NaN / 0

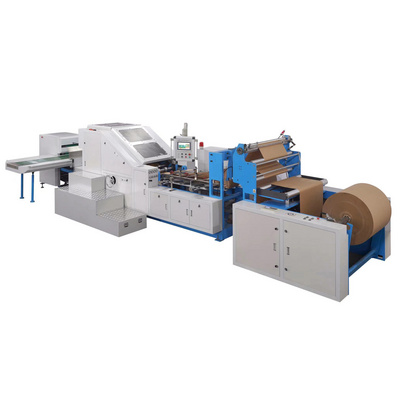

Product V-bottom Hand Holding Paper Bag Making Machine with Flexo Printing Machine Cement Bag Kraft Paper Bag Machinery Paper

Get Latest Price

US$ 78000

≥1 Pieces

Quick Details

Machine Type:

Bag Forming Machine

Bag Type:

Shopping Bag

Material:

Paper

Place of Origin:

Zhejiang, China

Product Details

Product Description

Performance and use:

This machine is used for roll primary color paper or printing roll paper such as kraft paper. Paper rolls such as food paper are completed by this machine at one time. Automatic center gluing, raw material into tube, cut to length, bottom indentation, bottom folding. Glue on the bottom and shape the bottom of the bag. Finished bag finishing is completed at one time. This machine is more convenient to operate, more efficient and more stable. It is an environmentally friendly paper bag machine equipment that produces various paper bags, snack food bags, bread bags, dried fruit bags, etc.

Main feature:

1.Using Willon touch screen man-machine interface, the operation function is clear at a glance, easy to control

2.Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability

3.Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size

4.The raw material loading and unloading adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic constant tension control.

5. The raw material correction adopts brushless servo motor to reduce the adjustment time of paper roll alignment.

Main feature:

1.Using Willon touch screen man-machine interface, the operation function is clear at a glance, easy to control

2.Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability

3.Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size

4.The raw material loading and unloading adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic constant tension control.

5. The raw material correction adopts brushless servo motor to reduce the adjustment time of paper roll alignment.

Technical parameters:

|

Model

|

XL-FD450

|

|

Cutting Length

|

270-530mm

|

|

Paper Bag Width

|

210-450mm

|

|

Bottom width

|

90-180mm

|

|

Paper bag thickness

|

80-150g/㎡

|

|

Mechanical speed

|

30-220pcs/min

|

|

Paper bag speed

|

30-150pcs/min

|

|

Paper roll width

|

660-1290mm

|

|

Paper diameter

|

1300mm

|

|

Inner diameter of paper

|

76mm

|

|

Total power

|

380V 3phase 4line 15kw

|

|

Total Weight

|

9000kg

|

|

Overall size

|

10000*3800*2200mm

|

|

Total weight

|

Total weight

|

|

outline

|

outline

|

Related Products

Packing&Shipping

Company Introduction

Founded in 2019, Wenzhou Xinlei Machinery Co., Ltd. is located in the beautiful city of Rui 'an, Wenzhou city, Zhejiang

Province.The factory area is 2100 cubic meters. Wenzhou Xinlei Machinery Co., Ltd. is a collection of production, scientific

research,sales as one, specializing in the production of a series of mask machine, spot welding machine, mask packaging machine, paper straw packaging machine, paper cup packaging machine, wipes packaging machine and other machinery. Since its establishment, the company has developed its own scientific research team, debugging team and sales team with high technology and high quality as the starting point and independent innovation. We adhere to the principle of "quality first, customer satisfaction". We sincerely provide customers with high-quality mask machine and packaging equipment, technology, raw materials one-stop service, and responsible for equipment installation, commissioning and technical personnel training.

Province.The factory area is 2100 cubic meters. Wenzhou Xinlei Machinery Co., Ltd. is a collection of production, scientific

research,sales as one, specializing in the production of a series of mask machine, spot welding machine, mask packaging machine, paper straw packaging machine, paper cup packaging machine, wipes packaging machine and other machinery. Since its establishment, the company has developed its own scientific research team, debugging team and sales team with high technology and high quality as the starting point and independent innovation. We adhere to the principle of "quality first, customer satisfaction". We sincerely provide customers with high-quality mask machine and packaging equipment, technology, raw materials one-stop service, and responsible for equipment installation, commissioning and technical personnel training.

FAQ

Q:Are you factory or trading company?

A: We are factory and manufacture.

A: We are factory and manufacture.

Q:The Lead time about one set?

A:about 7- 10 days

Q:what is the type about face mask ?

A:3-layer to 5-layer disposable face mask

Q:How about production speed?

A:80-100pcs/min

Q:How many workers need to operate the equipment?

A:need only 1 worker to operate

A:about 7- 10 days

Q:what is the type about face mask ?

A:3-layer to 5-layer disposable face mask

Q:How about production speed?

A:80-100pcs/min

Q:How many workers need to operate the equipment?

A:need only 1 worker to operate

Hot Searches