NaN / 0

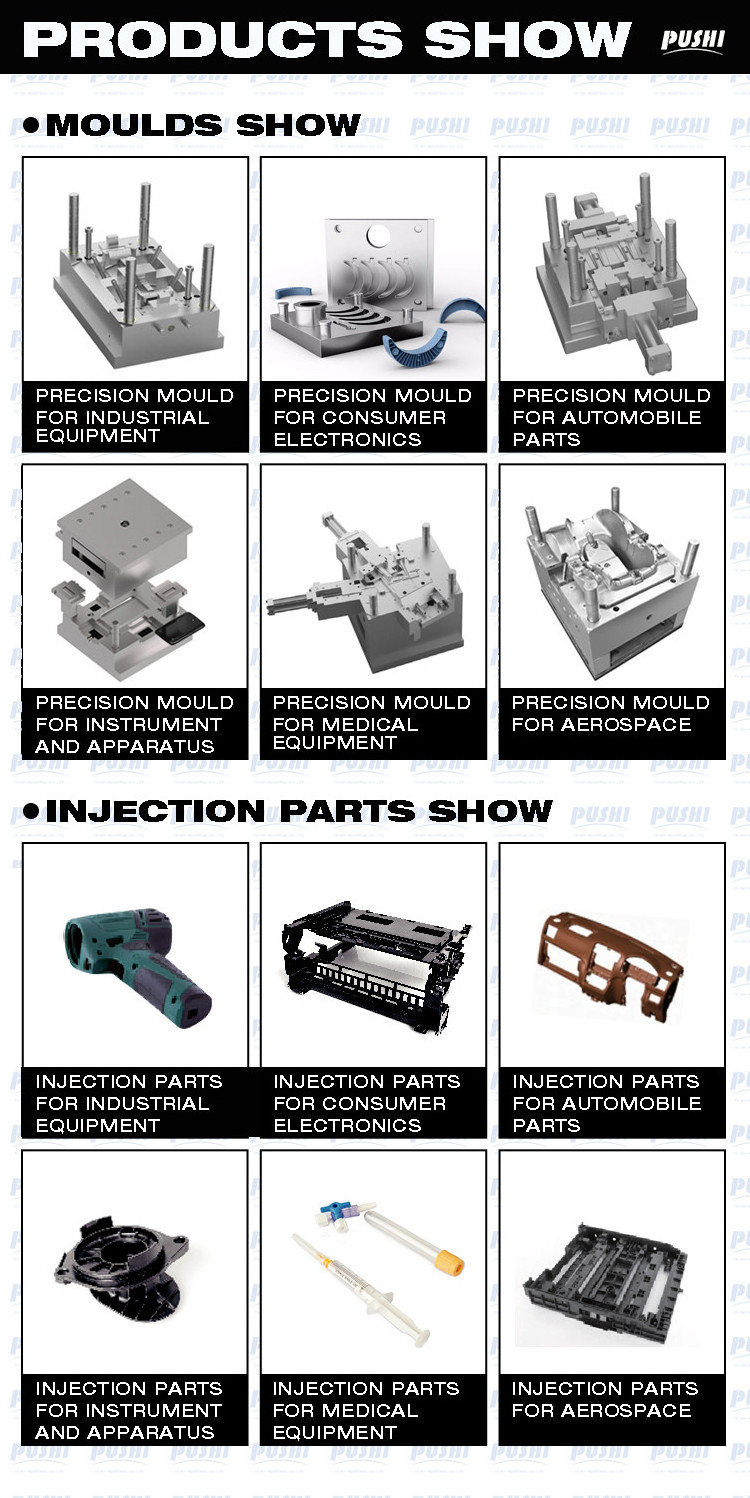

Precision Plastic Injection Mould Molds Split Air Conditioner Refrigerator Support Stand Bracket Base Moulds Mold Molding Parts

Get Latest Price

US$ 2600

≥1 Sets

US$ 2200

≥2 Sets

US$ 1600

≥3 Sets

Quick Details

Shaping Mode:

Plastic Injection Mould

Injection mold standard:

HASCO,DME,MISUMI,China lKM Standard.

Please provide:

2D, 3D, samples, or the size of the multi-angle pictures.

Mould material:

45#, 50#, P20, 738, 738H, 718, 718H, NAK80, 2316, 2316A, S136 etc.

Product Details

PRODUCT DESCRIPTION

|

SPECIFICATIONS FOR PUSHI INJECTION MOULDS

|

|

|

|

|||

|

Injection mold standard

|

HASCO, DME, MISUMI, China lKM Standard

|

|

|

|||

|

Please provide

|

2D, 3D, samples, or the size of the multi-angle pictures

|

|

|

|||

|

Mould material

|

45#, 50#, P20, 738, 738H, 718, 718H, NAK80, 2316, 2316A, S136, S136H etc

|

|

|

|||

|

Product material

|

ABS, PA6, PA66, PP, PC, TPU, POM, PBT, PVC, TPE, TPV, TPO, TPR, PE, HDPE etc

|

|

|

|||

|

Cavity

|

Single-cavity, Multi-cavity or by requested

|

|

|

|||

|

Runner system

|

Cold runner or Hot runner

|

|

|

|||

|

Mould precision

|

±0.01mm

|

|

|

|||

|

Mould Life

|

50-100 million shots

|

|

|

|||

|

Software

|

CAD, PRO-E, UG, Rhinoceros etc

|

|

|

|||

|

Design Time

|

1-3 days (normal circumstances)

|

|

|

|||

|

Main thechnology

|

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes etc

|

|

|

|||

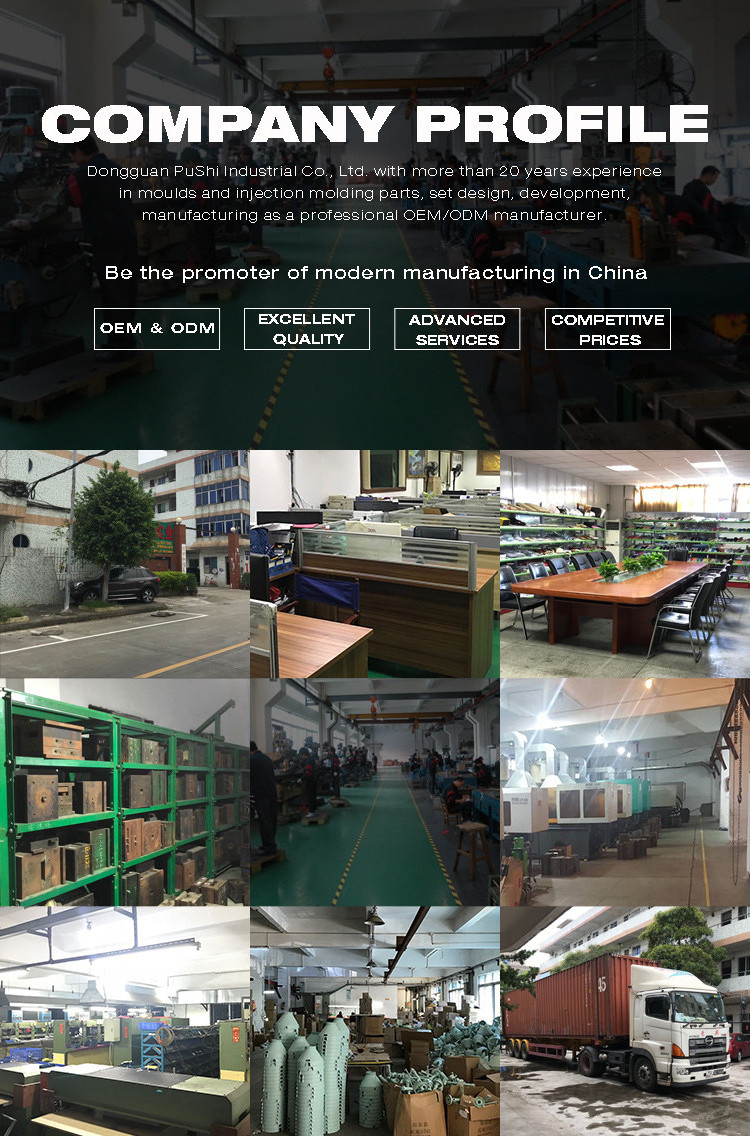

CUSTOM PROCESS

Customized injection mold steps

1. Customers will provide 3D drawings or sample inquiry, and we will quote according to 3D drawings or samples.

2. Negotiations include mold price, mold quality, mold material, mold cavity material, mold size, surface effects, technical requirements, mold life, warranty period, product weight, product cost, delivery time, logistics mode, payment mode, etc.

3. Confirm the order. Proforma invoice or commercial invoice.

4. T/T deposit. 50% T/T in advance ,balance before shipment.

5. DFM (Design For Manufacturing), Ensure quality. Mould design, mould drawing confirmation.

6. Mold processing. Feedback the processing progress every week, we will show you the pictures of mold processing.

7. Sample confirmation. Express sample, confirm sample, mass production.

8. Product packaging. Wooden case, carton or custom made.

9. Delivery. By Sea, By air, etc. Pay the balance.

CONTACT SUPPLIER