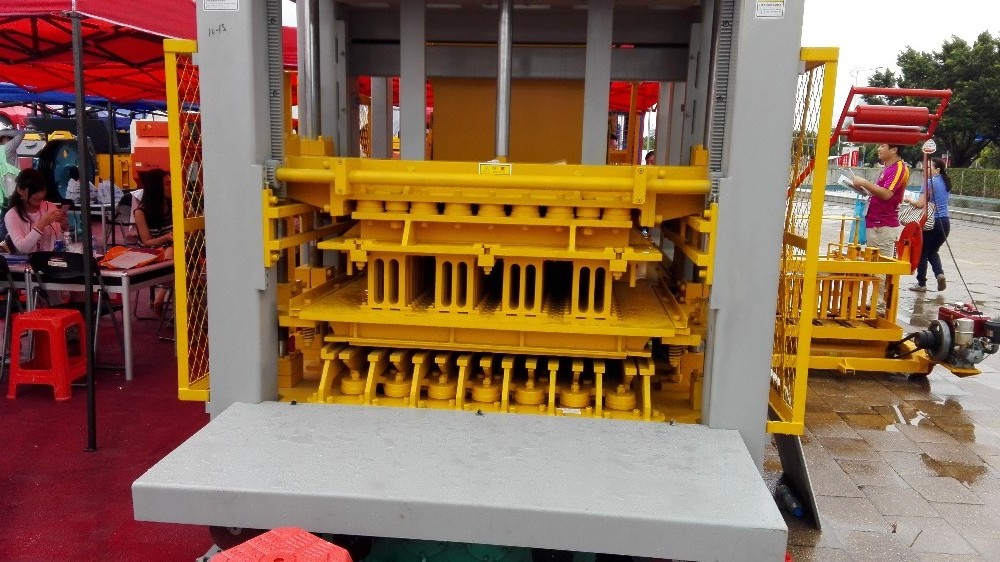

Name: Block making machine

Brand: HONGFA

Original: China

SIEMENS engines, large productivity, long in service life about 10 years. 200x200 square ipipe steel more stable

|

Host machine technical parameter

|

|

|

Item

|

details

|

|

Overall Dimension

|

9350×3200×2900(mm)

|

|

Rated pressure

|

21MPa

|

|

Main vibration form

|

Platform vibration

|

|

Acceleration of vibration

|

15-20g

|

|

Exciting force

|

110kn

|

|

Cycle Time

|

15-25 seconds

|

|

Vibrating Frequency

|

2800-4500 rolls/minute

|

|

Overall weight

|

12300kgs

|

|

Motors Power

|

67.18kw

|

|

Pallet Size

|

1300x900x30mm

|

|

Raw Materials

|

crushed stone, sand, cement, dust and coal fly ash, cinder,

slag, gangue, gravel, expanded perlite, and other industrial wastes |

|

Applied Products

|

concrete blocks, solid/hollow/cellular masonry products,

paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc |

|

|

|

Name: Block making machine

Brand: HONGFA

Original: China

SIEMENS engines, large productivity, long in service life about 10 years. 200x200 square ipipe steel more stable

Name:

PLC control

Brand:

SIEMENS

Original:

China

International famous PLC. Rich in functions, large in capacity, simple in operation and long in service life, ensure our machine work stably and continuously

Name:

Mould

Brand:

HONGFA

Original:

China

Raw meterial is manganese steel, its biggest advantage is wear resistance, treatment process is Carburization process with heat treatment, wire cutting, promise our mould can use 100000 times, not deformed

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

|

Packaging

|

|

|

|

Size

|

123 (L) * 456 (W) * 789 (D)

|

|

|

Weight

|

12.3 T

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Shandong Hongfa Machinery Co., Ltd is a construction and building materials equipments manufacturer mainly produce all kinds of AAC block making machine, concrete mixing plant, mixer, concrete block making machine, concrete tile making machine and concrete pipe making machine with more than 20 years experience and being the biggest manufacturer in China at present. All the products are conformity with the standard of the state, and gets the ISO9001-2008 Quality System Certificate, also honored as 'One of the Top Ten Famous Brands of Bricks & Tile Field in China' and other honors.

Office building

Our office building provides our staff with a comfortable working environment, thus we can keep improving our AAC

Machines and related service with higher productivity.

Block machine Components warehouse

Factory environment

Product inspection

Production technology

Welding workshop

CNC machining center

Assembly workshop

Finished product area