NaN / 0

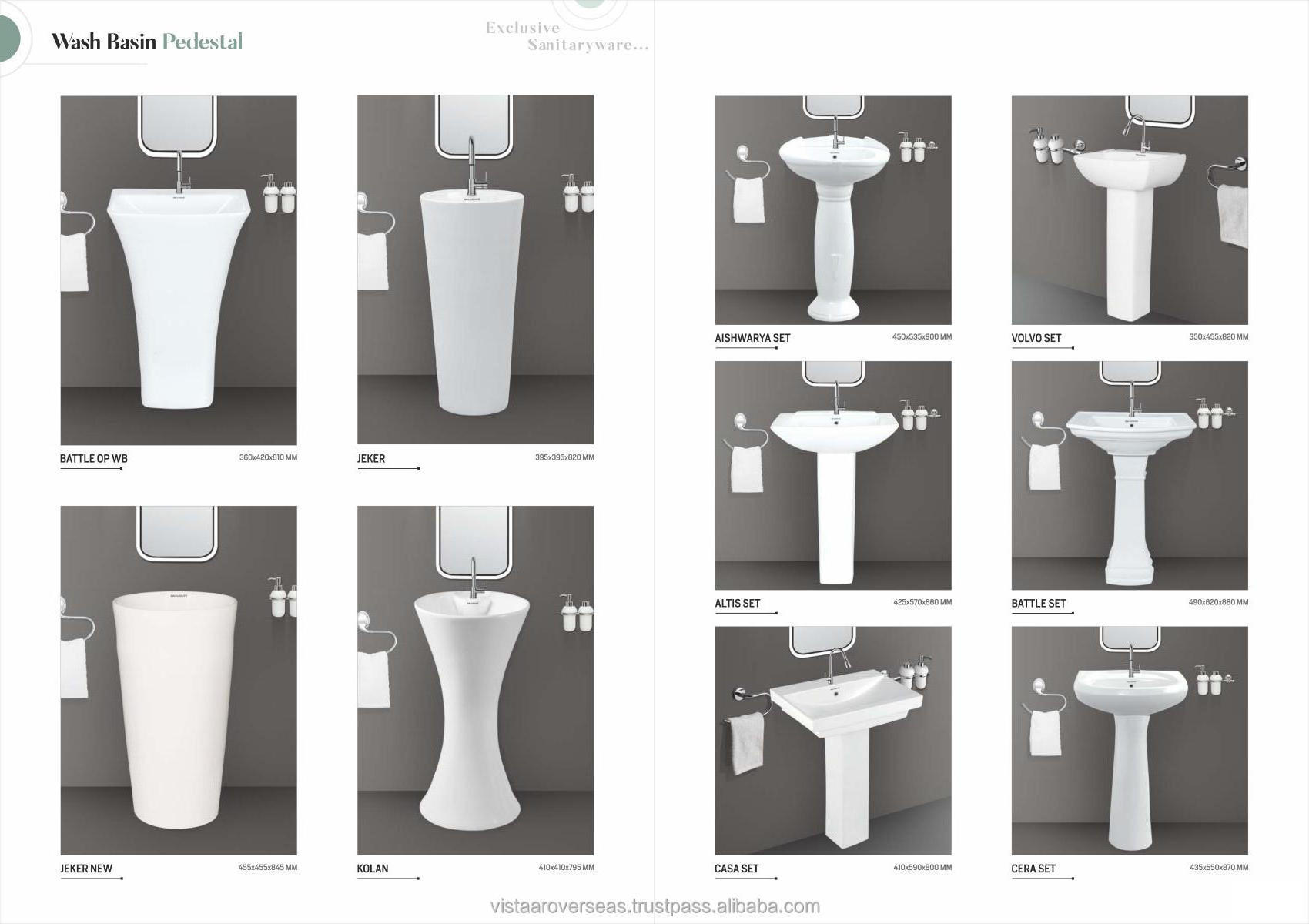

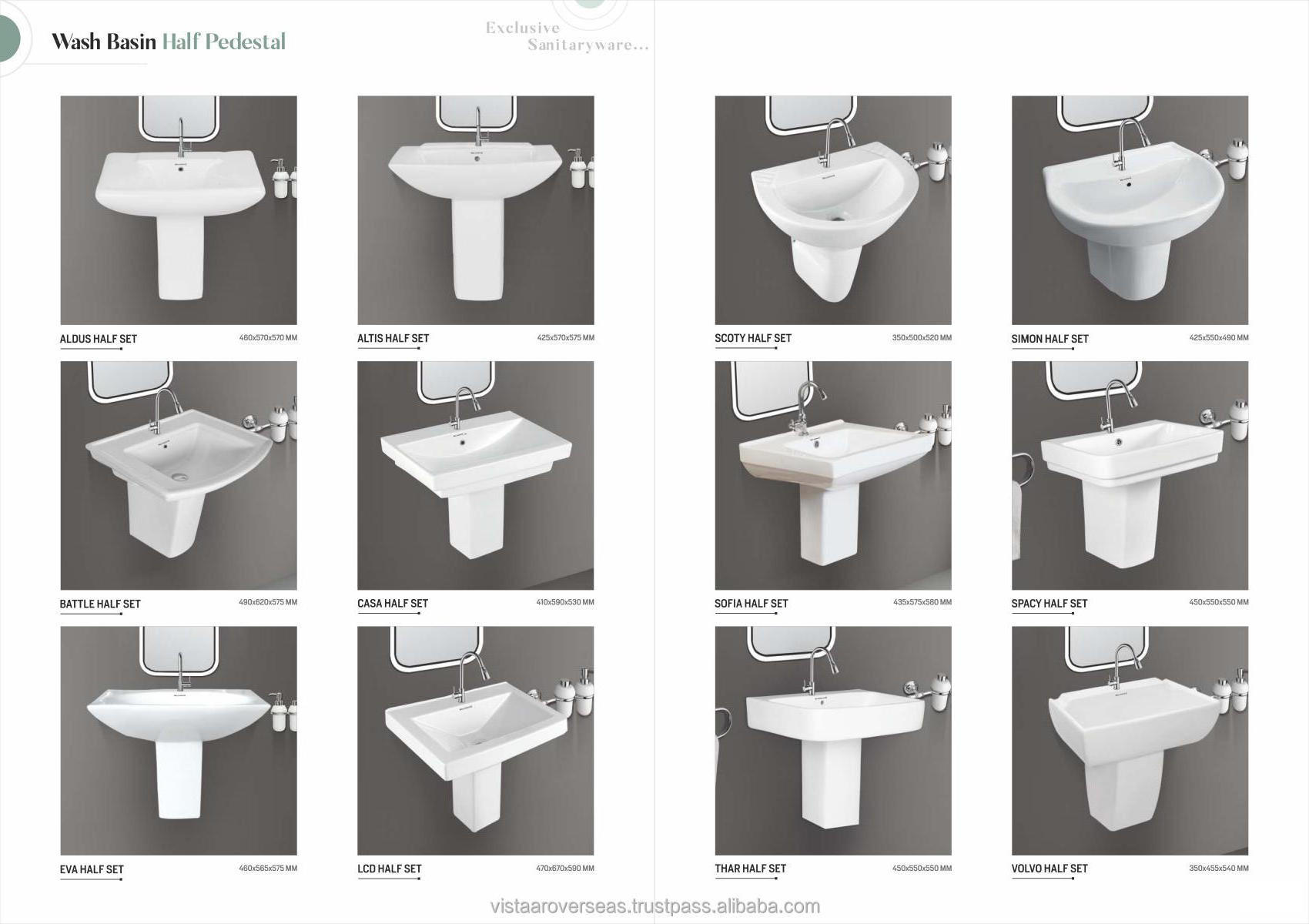

Modern European Style Bathroom Wash Basin Sink Marble Pedestal Basin Lavabo Pedestal Stand Ceramic Sanitary Ware for Export

Get Latest Price

US$ 22.95

≥50 Sets

US$ 16.55

≥250 Sets

US$ 13.25

≥1000 Sets

Quick Details

Project Solution Capability:

graphic design, 3D model design, total solution for projects

Application:

Hall

Design Style:

Victorian

Type:

Pedestal Sinks

Product Details

Products Description

Product Gallery / Factory Display

Technical Specification

|

Name of Test

|

As Per IS 2556 (Part) 1994

|

Vistaar's Value

|

||

|

Water Absorption

|

Average value should not exceed more than 0.5 %

|

Max 0.30 % show better vitrification.

|

||

|

Crazing Test

|

No crazing up to 2 cycle up 5 hrs each cycle or 10 hrs at pressure 0.34 to 0.37 Mps.

|

No problem up to 4 cycle and no crazing.

|

||

|

Chemical Resistance

|

No loss of reflectivity of the glaze when compared with control sample.

|

No loss of reflectivity of the glaze when compared with control sample.

|

||

|

Modules of Repture

|

Not less than 60 Mpa.

|

Minimum 65 Mpa. / Minimum 80 Mpa.

|

||

|

Resistance to Staining and Burning

|

No stain shall remain on either of test piece.

|

No stain shall remain on either of test piece.

|

||

|

Discoloration

|

None on all visible surface.

|

None on all visible surface.

|

||

|

Wavy Finish

|

None on all visible surface.

|

None on all visible surface.

|

||

|

Note : All products dimension may vary 10 % to 15 % from the dimension given in the catalogue.

|

|

|

||

Trouble Shooting Guide

|

PRODUCT

|

PROBLEM

|

PROBABLE REASONS

|

CORRECTIVE ACTIONS

|

||

|

One Piece Water Closet

|

Water not coming in Bowl area while flushing.

|

Mechanism inside tank may not be working properly.

|

Change the center pump of mechanism.

|

||

|

|

Water is continuously leaking Inside the Bowl.

|

There is no water in tank.

|

Increase the ball cock height to the maximum level.

|

||

|

|

Water Quantity insufficient for effective Flushing.

|

Mechanism inside tank may not be working properly.

|

Change the center pump of mechanism.

|

||

|

|

Uneven flow of water from both side of Closet.

|

Ball Cock height adjusted at lower level.

|

Increase the ball cock height to the maximum level.

|

||

|

|

Overflow chocked and foul bad odour.

|

Waste coupling used may be full threaded.

|

Waste coupling should be replaced by slot cut coupling.

|

||

|

|

Water deposit on tap platform area and inside.

|

Basin is not flued in level or bracket is not in level.

|

Should be done by proper leveling.

|

||

|

|

There is no tap hole in Basin.

|

Tap hole can be semi punched from back side.

|

Tap Hole should be created by plumber from semi punched area.

|

||

|

|

|

|

Insert the flush pipe up to the end of inlet for Pan / Closet check whether flush pipe is not covering flush hole which is in both side of inlet.

|

||

|

|

|

Closet / Pan may not be Levelled.

|

Should be done by proper levelling.

|

||

|

AFTER SALES SERVICE :

|

|

AFTER RECEIVING THE PRODUCTS, IF YOU FOUND ANY QUALITY PROBLEM, PLEASE CONTACT US IN TIME BY EMAIL. WE WILL DEFINETLY FIND A MOST SUITABLE SOLUTIONS FOR IT.

|

|

||

Similar Wash Basin Models

Packing Details

Corrugated Box Packing Pictures of Wash Basin & Pedestal

Live Pictures During Container Loading

Certificates

Our Collection

Why Choose Us ?

Customer Reviews