NaN / 0

Full Automatic Crispy Maize Chocos Corn Flakes Breakfast Cereals Processing Production Line Making Machine

Get Latest Price

US$ 25000

≥1 Sets

Quick Details

Applicable Industries:

Corn flakes factory

Marketing Type:

Hot Product 2020

Place of Origin:

Shandong, China

Brand Name:

KLD

Product Details

Full Automatic Crispy Maize Chocos Corn Flakes Breakfast Cereals Processing Production Line Making Machine

Product Description

Introduction:

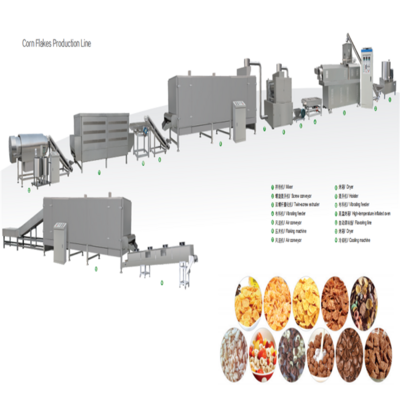

Full Automatic Crispy Maize Chocos Corn Flakes Breakfast Cereals Processing Production Line Making Machine is a fullly automatic line which combines our professional team with the European advanced technology; It is a breakthrough to solve the problems regarding to sticky material on the roller,low output of flakes pressing ,low shaping rate ,poor taste and so on .Resonable equipments collocation and realizable process control ensure high quality and delicious corn flakes production.The processing line not only reduces costs by improving efficiency, but also improves market competitiveness.

Sample:

Flow

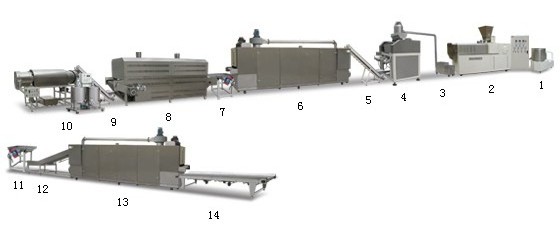

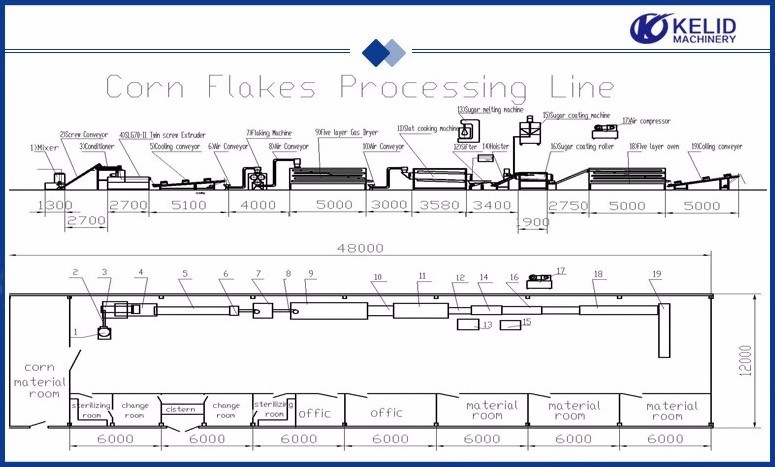

Corn——Miller——Mixer——Screw Conveyer—— Twin Screw Extruder——Cooling Conveying——Air Conveyer——Flaking Machine——Air Conveyer——Three-layer Oven —— Hoister ——Cooker——Sifter——Melting Sugar Machine ——Sprayer Sugar ——Hoister ——Roller ——Air Compressor——Five-layer Oven——Cooling Machine

Euipment Parameters:

|

Model

|

KLD65

|

KLD70

|

KLD85

|

|

Installed power

|

76kw

|

95kw

|

178kw

|

|

Power consumption

|

54kw

|

66kw

|

125kw

|

|

Capacity

|

120- 160kg/h

|

200- 260kg/h

|

300-400 kg/h

|

|

Dimension

|

1700*2000*2500mm

|

2200*2000*2500mm

|

2600*2000*3500mm

|

Parts details:

Our Services

1. Free consultation service before, during, and after sales;

2. Free Project planning and design services upon clients' special demands;

3. Debugging and inspecting of equipment until everything is functional before leaving the factory;

4. Overseas installation and training of equipment maintenance and operating personally;

5. Provide basic production techniques and formulas;

6. 1 year complete warranty.

Packaging & Shipping

Packaging: Inside ( Plastic film ) / Outside ( Wooden case )

Transportation: Shipping, train, express or upon your demands.

Hot Searches