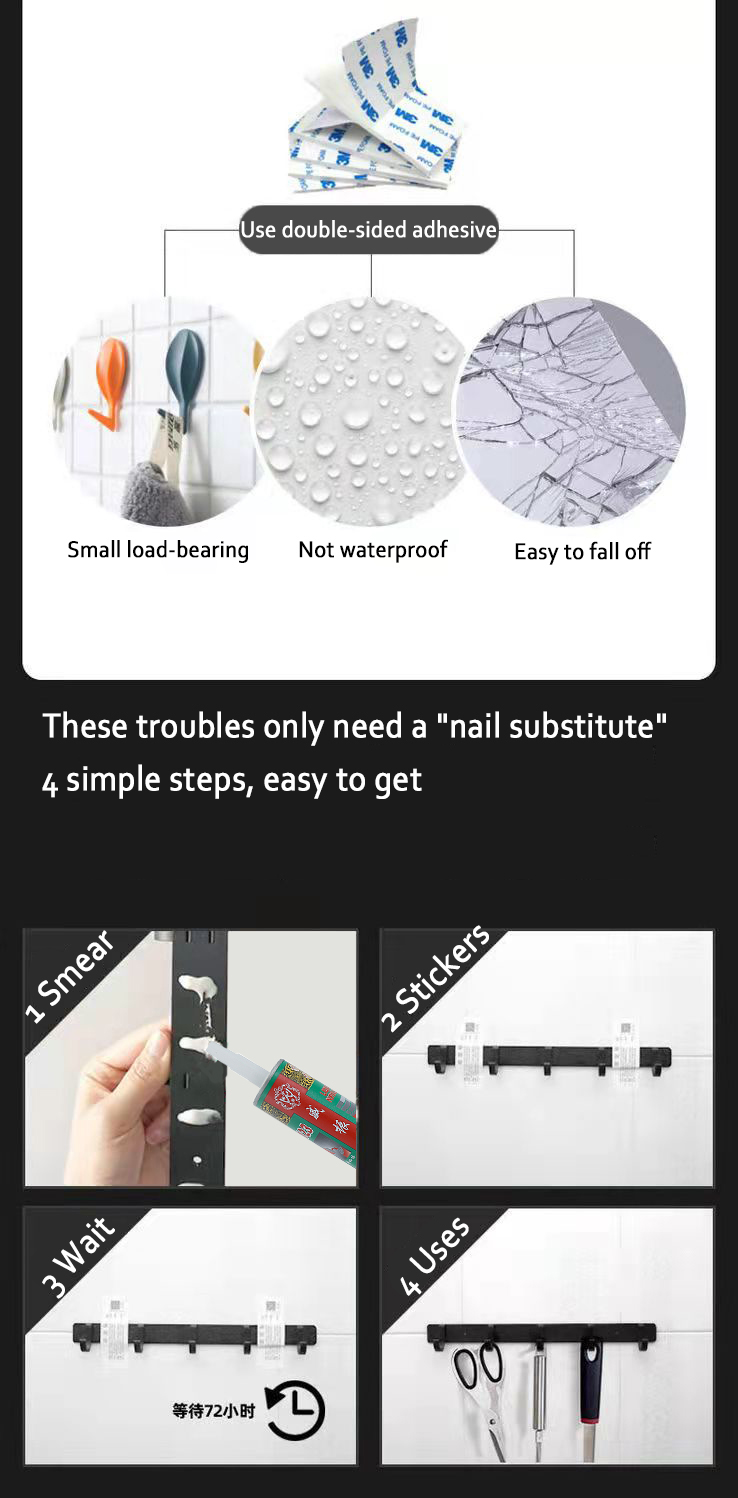

1. Surface preparation: Bonding surface should be clean and free of dust and rust.

2. Cut up the tube top, put the adhesive mouth and squeeze out the adhesive by sealing gun.

---Dry Bonding: (suitable for light materials & joints for light pressure)

Squeeze out the adhesive in form of "Z" ,line distance about 40cm.

Apply to material A, then press to bonding area B lightly, wait for a few minutes about 5~8 minutes, then press the two surfaces with strong pressure.

---Wet Bonding: (Suitable for heavy materials)

Apply the adhesive same way as above, then clamp or fasten up the two materials by tools like pliers, screws to maintain maximum surface contact at bonded interfaces. Fix and wait for 24 hours till the adhesive dries, then remove the fixing tools.

---Wet Bonding: (Suitable for heavy materials)

Apply the adhesive same way as above, then clamp or fasten up the two materials by tools like pliers, screws to maintain maximum surface contact at bonded interfaces. Fix and wait for 24 hours till the adhesive dries, then remove the fixing tools.

The adhesive is movable within 20 minutes since bonding, becomes stronger 2~3 days after bonding, reaches best performance till 2-3 days.