NaN / 0

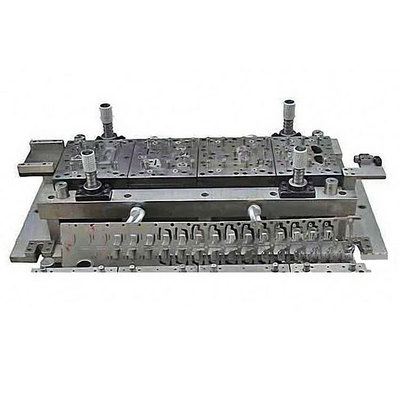

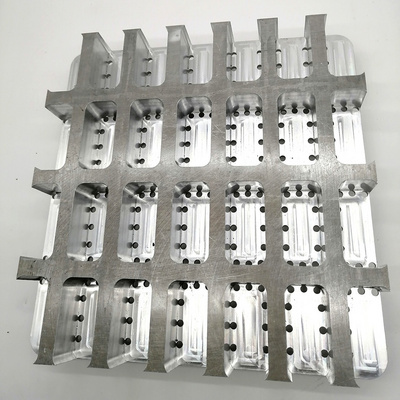

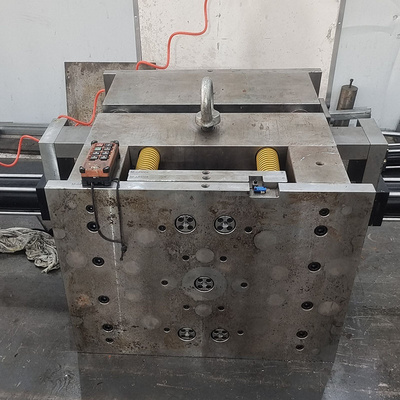

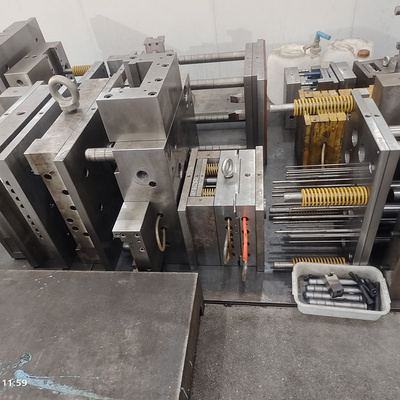

OEM stamping part stamping moulds punching dies mould stamping die stamping metal mould

Get Latest Price

US$ 50

≥1 Sets

US$ 30

≥5 Sets

Quick Details

Shaping Mode:

Punching Mold

Place of Origin:

Fujian, China

Brand Name:

Wisely

Model Number:

WM-5

Product Details

Product Description

|

High Precision Mold

|

|

|

|

|

||||

|

Core/cavity material:

|

S136, P20, 718, 8407, NAK80, H13 etc.

|

|

|

|

||||

|

Mould base material:

|

LKM, HASCO, DME

|

|

|

|

||||

|

Runner:

|

Cold/ hot runner

|

|

|

|

||||

|

Sprue gate:

|

Pinpoint gate, submarine gate etc...

|

|

|

|

||||

|

Cavity qty.:

|

Single or multiple

|

|

|

|

||||

|

Mould life:

|

300,000~1,000,000 shoots

|

|

|

|

||||

|

Size/Tolerance:

|

According to customer's 2d drawing

|

|

|

|

||||

|

Monthly capacity:

|

500000pcs

|

|

|

|

||||

|

Design Software:

|

PROE, UG, CAD,Solidwork

|

|

|

|

||||

|

Order processing procedures

|

|

|

|

|

||||

|

1. Confirm drawing, order qty, surface treatment, packing, shipping and price.

|

|

|

|

|

||||

|

2. Make pre-production samples.

|

|

|

|

|

||||

|

3. Mass production.

|

|

|

|

|

||||

|

4.Customer inspection or self-inspection as customer's requirements.

|

|

|

|

|

||||

|

5. Arrange shipment. We can provide shipping assistants, customers can also arrange shipments themselves.

|

|

|

|

|

||||