NaN / 0

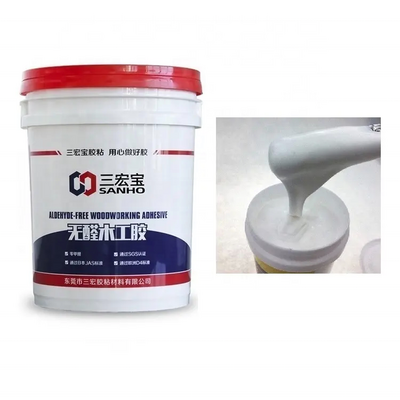

White PVCA Latex Glue Vinyl acetate and polyvinyl alcohol polymers wood glue

Get Latest Price

US$ 29

≥30 Pieces

US$ 28.5

≥100 Pieces

US$ 28

≥500 Pieces

Quick Details

CAS No.:

none

Place of Origin:

Shandong, China

Brand Name:

DM

Model Number:

DM-310

Product Details

Product Description

【product description】

High-performance dispersed single-component adhesive, suitable for indoor bonding of homogeneous or composite PVC coils or sheets, stone-plastic sheets, foam-backed vinyl floors, PVC floors pasting on facades and walls as panels,etc. Also suitable for bonding on non-absorbent substrates such as tiles. For various elastic floor backings, it has high initial

and final adhesive strength and reliable performance, and can be used for pasting elastic floors of hot water pipe geothermal heating floors. On the base layer that has not been self-leveled but relatively flat, it can also stick to the above-mentioned types of floors with deeper scrapers such as A2.

and final adhesive strength and reliable performance, and can be used for pasting elastic floors of hot water pipe geothermal heating floors. On the base layer that has not been self-leveled but relatively flat, it can also stick to the above-mentioned types of floors with deeper scrapers such as A2.

【Scope of application】

Indoor and outdoor.

Indoor and outdoor.

【Pasting method】

• Stir evenly before use, and spread evenly on the base house with A1 or A2 scraper. • Semi-wet application of all types of floor coverings on absorbent surfaces such as finished sanded self-leveling substrates, i.e. to dry glue after 10-25 minutes, the rubber belly is semi-dry and semi-wet, touch the rubber surface with your fingers, it is sticky, and when the glue can also stick to your fingers, you can lay the floor. After paving, use metal rollers or other tools to compact the floor to remove the air under the floor. The open time for working is 60 minutes. •Dense non-absorbent floor such as tiles, etc., use pressure-sensitive method to paste PVC or vinyl floor with foam bottom, that is, to dry glue 60-120 after 10 minutes, wait for the adhesive film to dry completely and then paste the floor. After laying, use metal rollers or other tools to compact the floor to remove the air under the floor. The open time for working is 60-90 minutes. • Paste on the facade, use the contact paste method. That is to say, glue on the back of the floor and the facade respectively, and stick it when the first side is dry and the last side is half dry and half wet. Press again. In actual ground construction, the method of gluing on one side is also often used. Can be determined by trial paste.

【Precautions】

1. It is necessary to ensure the best temperature and humidity conditions for ventilation and construction. If the temperature is too low or the humidity is too high, it will prolong the drying time and delay the development of bond strength.

2. This product should be protected from severe cold and sunlight during transportation, storage and construction.

【Coating rate】

On the polished self-leveling base, about 5 square meters per kilogram of

glue can be coated with A1 scraper teeth, and about 4.5 square meters per kilogram of A2 scraper teeth can be coated. On ceramic tiles, about 6 square meters per kilogram can be coated with A1 scraper.

glue can be coated with A1 scraper teeth, and about 4.5 square meters per kilogram of A2 scraper teeth can be coated. On ceramic tiles, about 6 square meters per kilogram can be coated with A1 scraper.

【Precautions】

1. It is necessary to ensure the best temperature and humidity conditions for ventilation and construction. If the temperature is too low or the humidity is too high, it will prolong the drying time and delay the development of bond strength.

2. This product should be protected from severe cold and sunlight during transportation, storage and construction.

【Coating rate】

On the polished self-leveling base, about 5 square meters per kilogram of glue can be coated with A1 scraper teeth, and about 4.5 square meters per kilogram of A2 scraper teeth can be coated. On ceramic tiles, about 6 square meters per kilogram can be coated with A1 scraper.

Product Applications

【Pasting method】

1.Stir evenly before use, and spread evenly on the base house with A1 or A2 scraper. • Semi-wet application of

all types of floor coverings on absorbent surfaces such as finished sanded self-leveling substrates, i.e. to dry glue after 10-25minutes, the rubber belly is semi-dry and semi-wet, touch the rubber surface with your fingers, it is sticky, and when the glue can also stick to your fingers, you can lay the floor. After paving, use metal rollers or other tools to compact the floor to remove the air under the floor. The open time for working is 60 minutes.

all types of floor coverings on absorbent surfaces such as finished sanded self-leveling substrates, i.e. to dry glue after 10-25minutes, the rubber belly is semi-dry and semi-wet, touch the rubber surface with your fingers, it is sticky, and when the glue can also stick to your fingers, you can lay the floor. After paving, use metal rollers or other tools to compact the floor to remove the air under the floor. The open time for working is 60 minutes.

2.Dense non-absorbent floor such as tiles, etc., use pressure-sensitive method to paste PVC or vinyl floor with foam bottom, that is, to dry glue 60-120 after 10 minutes, wait for the adhesive film to dry completely and then paste the floor. After laying, use metal rollers or other tools to compact the floor to remove the air under the floor. The open time for working is 60-90 minutes.

3.Paste on the facade, use the contact paste method.

That is to say, glue on the back of the floor and the facade respectively, and stick it when the first side is dry and the last

side is half dry and half wet. Press again. In actual ground construction, the method of gluing on one side is also often used. Can be determined by trial paste.

That is to say, glue on the back of the floor and the facade respectively, and stick it when the first side is dry and the last

side is half dry and half wet. Press again. In actual ground construction, the method of gluing on one side is also often used. Can be determined by trial paste.

Certifications

Recommend Products

Packing & Delivery

【Packaging】

Net weight 20KG/drum

Net weight 20KG/drum

Hot Searches