2. Easy Identification of Product

Tilt and Surface Defects: Achieves comprehensive detection without blind spots.

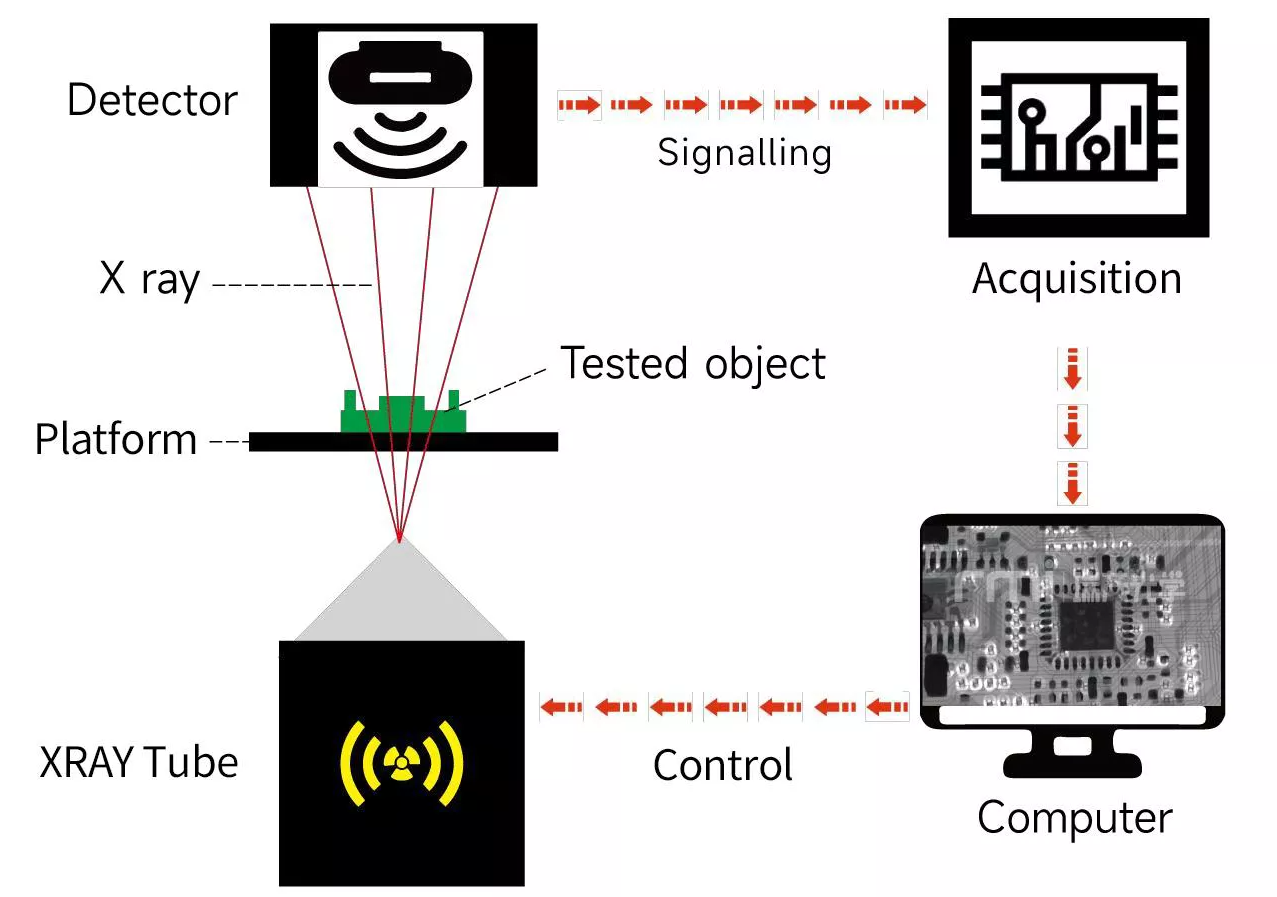

3. Utilizes Top-tier HAMAMATSU × X-ray Source from Japan: Incorporates cutting-edge smt X-ray machinetechnology for precision.

4. Effortless Detection of Semiconductor Package Wire Bending and Breakage: Detects bent or broken semiconductor package wires with ease.

Tilt and Surface Defects: Achieves comprehensive detection without blind spots.

3. Utilizes Top-tier HAMAMATSU × X-ray Source from Japan: Incorporates cutting-edge smt X-ray machinetechnology for precision.

4. Effortless Detection of Semiconductor Package Wire Bending and Breakage: Detects bent or broken semiconductor package wires with ease.