NaN / 0

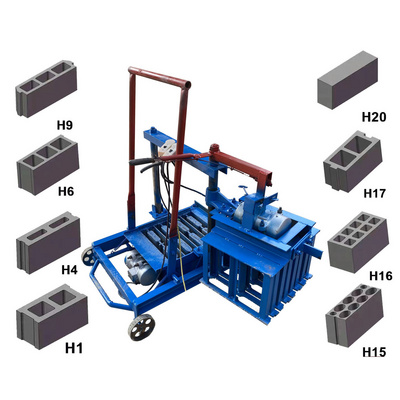

concrete block maker/brick making machine/pallet for concrete block

Get Latest Price

US$ 800

≥1 Sets

US$ 700

≥5 Sets

US$ 600

≥20 Sets

Quick Details

Type:

Hollow Block Making Machine, Paving Block Making Machine, Curbstone Block Machine

Brick Raw Material:

Cement

Production Capacity (Pieces/8 hours):

2500 pcs/8hours, 12000 pcs/8hours

Brick size:

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

Product Details

concrete block maker/brick making machine/pallet for concrete block

|

|

The small cement hollow block machine equipment mainly uses cement, stone, sand, fly ash, etc. as raw materials, scientifically proportioned, stirred, and pressed to form the mechanical equipment to produce concrete hollow blocks. The equipment is an environmentally friendly hollow block machine with excellent quality, low power consumption, easy operation and durability. It is very suitable for investors who initially enter the block industry or build a small hollow block factory.

|

|

| technical parameter | |

| technical parameter | 4-7(can be customized) |

| molding cycle | 35s |

| Total power | 4.8KW |

| Yield | 2500-3500 |

Features and configuration:

1. The body is all welded with strong square steel, which is extremely strong and resistant to vibration and has stable performance.

2. The mold box adopts column sliding, with compact coordination, synchronous and stable lifting, and the block forming rate is greatly improved.

3. The pressing head can slide and shift, which is convenient for mould box cloth and greatly improves the efficiency.

4. It is installed on the lifting part of the mold box to prevent the press head from damaging the machine in action.

5. When the vibration is applied, the vibration is excited at the same time, so that the four walls of the mold box are equally stressed, so as to achieve the forming effect, and ensure that the block density is high, and the edges and corners are neat and beautiful.

brick making machine in namibia/moving block machine

Hot Searches