NaN / 0

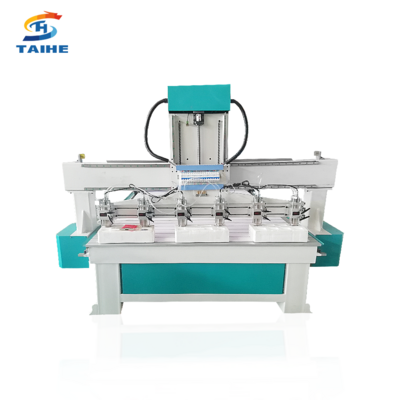

High Quality Multi BMG-1325M 3D CNC router machine price for woodworking advertisement sign metal engraver cutting

Get Latest Price

US$ 8990

≥1 Sets

US$ 8800

≥5 Sets

Quick Details

Working Table Size(mm):

1300*2500mm

Machine Type:

CNC Router

Range of Spindle Speed(r.p.m):

1 - 24000 rpm

Positioning Accuracy (mm):

0.05 mm

Product Details

High Quality Multi BMG-1325M 3D CNC router machine price for woodworking advertisement sign metal engraver cutting

Product Description

Application field and material :

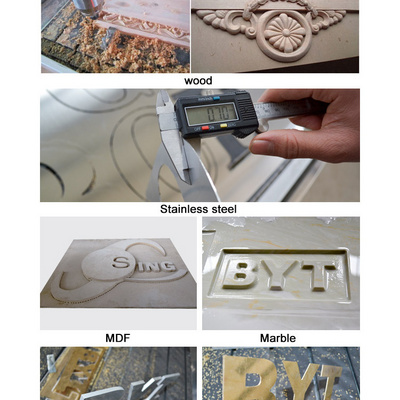

1. Advertising industry: Acrylic, two-color board, PVC, ABS board, aluminum-plastic board engraving and cutting, all kinds of signs, badges, signage, copper, fonts, all kinds of signs, trademarks and other materials.

2. Crafts industry: artificial stone crafts, souvenirs on the various types of text, graphics.

3. Mold processing: architectural model, physical model, bronzing mold, high frequency mode, micro injection mold, shoe mold, badge, embossing mold, biscuit, chocolate, candy mold.

4. Seal industry: E asily engraving on horns, plastics, organic boards, wood, storage mats, etc.

5. Woodworking industry: furniture decoration, musical instrument industry, wooden handicraft industry, large-area plate flat engraving, solid wood furniture, solid wood art murals, MDF paint-free doors, composite doors, cabinet doors, screen engravings, etc.

6. Mold industry: can engrave different molds, wood molds, aviation wood molds, propellers, automotive foam molds and so on.

Features:

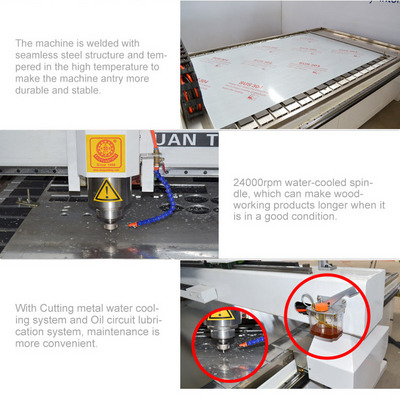

1. 4.5KW high-precision special engraving and milling water-cooled spindle, suitable for engraving and cutting of metal and non-metal materials.

2. Weihong NK105 handle control makes the work better and the operation is simpler.

3. Adopting imported linear guides, lead screws and special racks from Taiwan to ensure long-term high-precision operation of the equipment.

4. Install oil lubrication system for lubricate ball screws and rails easily.

5. With water cooling system for cutting metal .

6 . Professional custom-made heavy bed and gantry to ensure the stability of continuous cutting metal.

7. High precision r acks and pinion transmission ,with fast speed, and bear heavy press.

8. T-slot table, with anti corrosion water tank,easy to use clamp to fix material.

9. Good software compatibility , can use CAD/Artcam/Artcut software ,meantime we provide legitimate Artcut operating software and instructions.

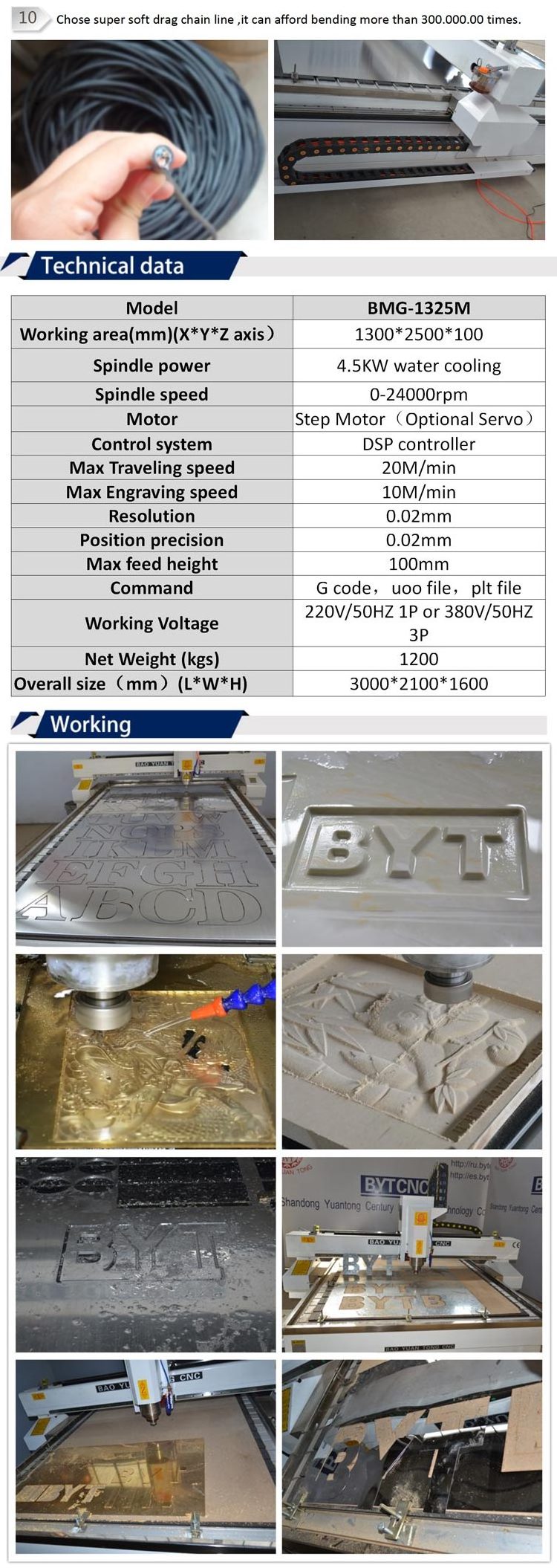

10.Chose super soft drag chain line ,it can afford bending more than 300.000.00 times.

Technical data:

|

Model |

BMG-1325M |

|

Working area(mm)(X*Y*Z axis) |

1300*2500*100 |

|

Spindle power |

4.5KW water cooling |

|

Spindle speed |

0-24000rpm |

|

Motor |

Step Motor( Optional Servo ) |

|

Control system |

DSP controller |

|

Max Traveling speed |

20M/min |

|

Max Engraving speed |

10M/min |

|

Resolution |

0.02mm |

|

Position precision |

0.02mm |

|

Max feed height |

100mm |

|

Command |

G code, uoo file , plt file |

|

Working Voltage |

220V/50HZ 1P or 380V/50HZ 3P |

|

Net Weight (kgs) |

1200 |

|

Overall size( mm ) (L*W*H) |

3000*2100*1600 |

Packaging & Shipping

For the Package usually Most of time we use plywood case package , but only few customer choose PE film package . However, no matter which kind of packing is used, we must ensure the safety of the equipment in transportation.Here is the America customer feedback on our package:

Feedback

Our responsibility -- provide stable and reliable performance of the equipment and provide high-quality service, let every user satisfaction. Contact with us get video feedback

Why us

Company Experience

1.Founded in 1996, with registered trademarks "BAOYUANTONG" and "BYT".

2.Own more than 30 patents for invention, utility model and design.

3.Passed the "SGS certification" for 9 consecutive years, and all products have obtained the " Europe CE certification"

4.Exported to over 150 countries including the North America, Europe, South America, the Middle East,and have more than 2000 clients.

5.Provide one-stop procurement ,let customer’s purchase more efficient and safety.

6.According the customer different requirements ,provide equipment customized solved plan and sample making .

Sales Service

1.Technical people have professional english ability and directly with customer communication.

2.24H/7D on line service , when you need we all will be here .

3.Before delivery , accept the international third party finish inspection .

4.Regular return visits to customers for technical guidance, and get high praise from customers.

5.For the products making , have professional technical engineer provide process guide .

Various Training Service

1.Provide U disk with detailed operation manual and video.

2.Via on line chat way service(QQ,whatsapp,wechat) for customer in any time.

3.Via teamviewer remote control software to provide on line guidance.

4. Customer come to our factory for learning how to operate the machines.

5.Engineer can go aboard for training if customer needed

Hot Searches