NaN / 0

KIE-C700 All in one curve and straight edge banding machine curved panel edge bander desk banding machinemachine

Get Latest Price

US$ 6350

≥1 Sets

US$ 5583

≥3 Sets

Quick Details

Place of Origin:

Guangdong, China

Brand Name:

Holyiso

Voltage:

220 V/380V /415V / Customize

Dimension(L*W*H):

1550*1400*1350mm

Product Details

Products Description

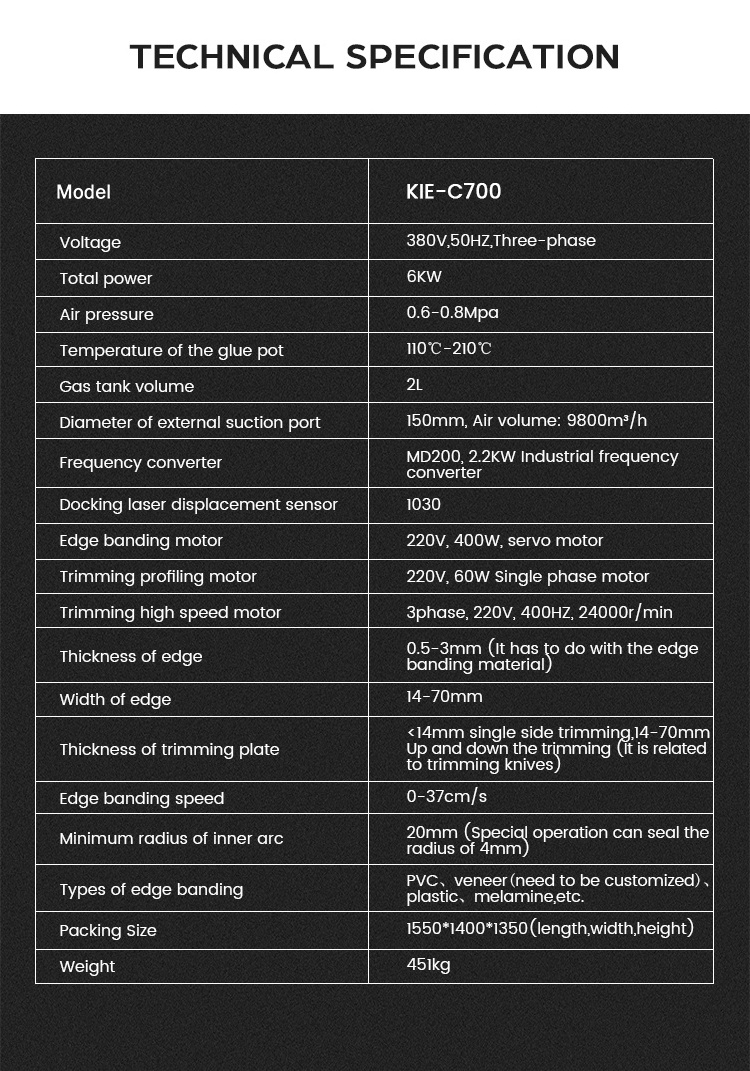

KIE-C700

Curve and Straight Edge Banding Trimming Machine

Application:

The machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, plywood etc,straight line edging and trimming. Edging smoothly and edging line is straight. The machine is stable, reliable and durable, with favorable price. It is especially suitable for large and medium-sized furniture manufacturers.

Features:

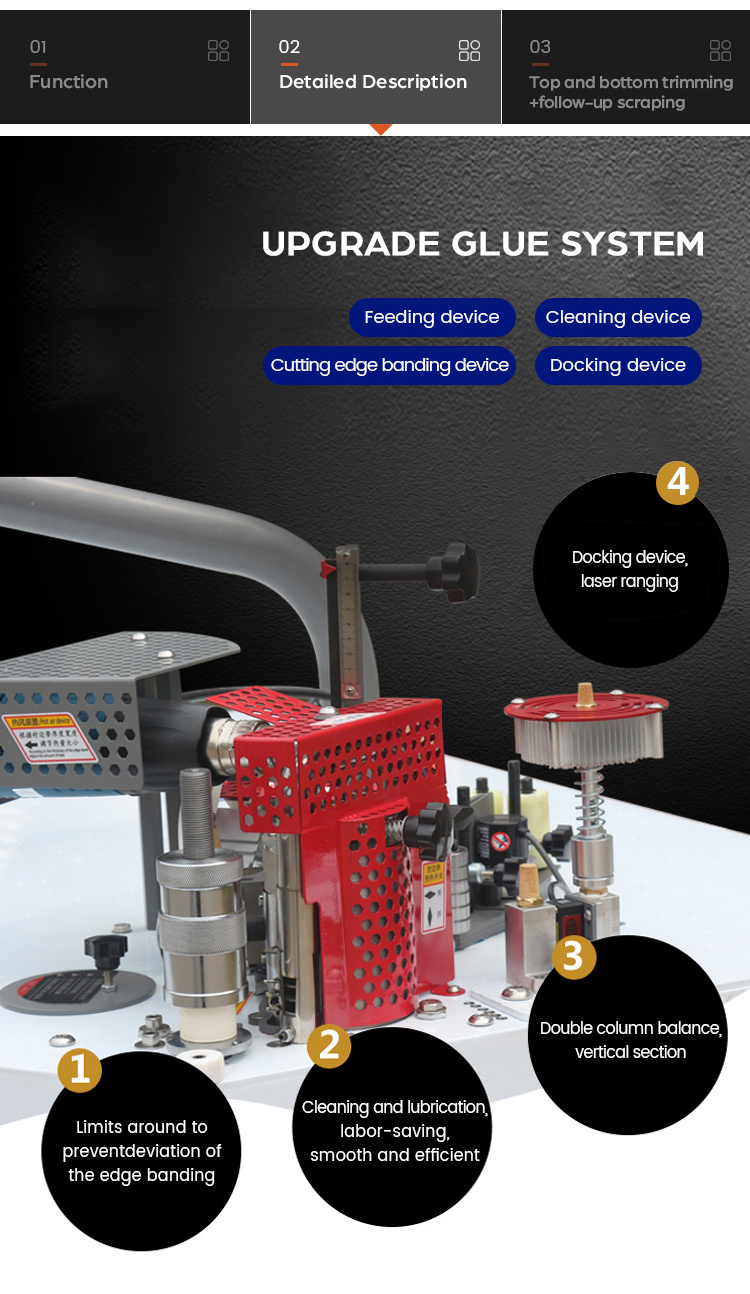

1. Limits around to prevent deviation of the edge banding

2. Cleaning and lubrication, labor-saving, smooth and efficient

3. Double column balance, vertical section

4. Docking device, laser ranging

Advantage:

1.Adopt domestic famous motor and high quality electrical components.

2.The fuselage is firm and steady,thus increasing the stability of the whole machine.

3.Aluminum alloy beam is a relatively advanced method, its precision and straightness are far superior to cast iron.

4.Auto cleaning, high precision, high efficiency.

5.The machine can be customized.

6.Automatic and precise gluing procedure as well integrated double finishing side within one workflow .The end cutting can be done at the rear side of the machine.

7.Multiple Air cylinder will assembled on the machine, mainly used for positioned location assured the panel materials processing accuracy in a very high level.

The machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, plywood etc,straight line edging and trimming. Edging smoothly and edging line is straight. The machine is stable, reliable and durable, with favorable price. It is especially suitable for large and medium-sized furniture manufacturers.

Features:

1. Limits around to prevent deviation of the edge banding

2. Cleaning and lubrication, labor-saving, smooth and efficient

3. Double column balance, vertical section

4. Docking device, laser ranging

Advantage:

1.Adopt domestic famous motor and high quality electrical components.

2.The fuselage is firm and steady,thus increasing the stability of the whole machine.

3.Aluminum alloy beam is a relatively advanced method, its precision and straightness are far superior to cast iron.

4.Auto cleaning, high precision, high efficiency.

5.The machine can be customized.

6.Automatic and precise gluing procedure as well integrated double finishing side within one workflow .The end cutting can be done at the rear side of the machine.

7.Multiple Air cylinder will assembled on the machine, mainly used for positioned location assured the panel materials processing accuracy in a very high level.

Details Images

Finish Product

Send Inquiry

Why Choose Us

Packing&Shipping

1.Delivery:

We can guarantee delivery on time.

We can guarantee delivery on time.

We also can sign on-time delivery contracts. If we can’t deliver on time, we will give the product a corresponding discount.

2.Package:

We will take care of your machinery packages well like picture show.Our workers will make sure your machine clean before package. We will add stretchy film for the whole machine and spare parts for delicate protection.We will make export standard strong Wooden box case package as your request.

2.Package:

We will take care of your machinery packages well like picture show.Our workers will make sure your machine clean before package. We will add stretchy film for the whole machine and spare parts for delicate protection.We will make export standard strong Wooden box case package as your request.

3.Guarantee:

The machine is guaranteed for 12 months .Within 12 months under normal using and maintenance, if the machine has something problem,you will get spare part for free . More than 12 months,you will get the cost price for accessories. You will also get technical support and service all the time.

4.Technical support:

Technical support by Phone, Email, Wechat, WhatsApp and Skype, 24 hours online.

We provide English version manual and Operational video.

Engineer available to service machinery overseas.

The machine is guaranteed for 12 months .Within 12 months under normal using and maintenance, if the machine has something problem,you will get spare part for free . More than 12 months,you will get the cost price for accessories. You will also get technical support and service all the time.

4.Technical support:

Technical support by Phone, Email, Wechat, WhatsApp and Skype, 24 hours online.

We provide English version manual and Operational video.

Engineer available to service machinery overseas.

5.After sales services:

Our machine is installed and tested well before delivery. You can operate the machine immediately after receiving machine.If you don't know how to use the machine, we will offer you free training until you can use machine freely. And If there is stillhave any question, please contact us by Email, Skype, Wechat, WhatsApp, Phone and Trade Manager online service at any time.

Our machine is installed and tested well before delivery. You can operate the machine immediately after receiving machine.If you don't know how to use the machine, we will offer you free training until you can use machine freely. And If there is stillhave any question, please contact us by Email, Skype, Wechat, WhatsApp, Phone and Trade Manager online service at any time.

FAQ

1.What’s the different between Rough trim&Fine trim?

Rough trim&Fine trim can trim the exceeding edge on the top and bottom side of the panel to be more smooth.Fine trimming can be upgraded to pneumatic adjustment knife edge for increased productivity and precision.

2.Will the machine be debugged before leaving the factory?

Surely yes,our machines are commissioned before leaving the factory to ensure that every function is available. However, we suggestion that the machine be adjusted according to its actual panel after it arrives.

3.Can I pause some features if I don't want to use ?

In addition to the scraping function, most other functions can be pause.

4.Can I customize the features I want?

Of couse,we are special in woodworking manufacturer and exporter of quality woodworking machines in Guangzhou, China. We have been in this field for more than 20 years.We have the ability to provide professional services for you.

5.Can the edge banding machine only seal the edges straight?

We also have fully automatic Partial hypotenuse edge banding machine.

6.How much temperature reach can it work ?

Generally,when reaches 150 ° it can test the board .The best working temperature is 180°.

7.what features can be upgraded?

A.Full range of products can be customized to feed in the opppsite direction.

B.Pneumatic adjustment(Including trimming and scraping)

C.Heavy-duty pneumatic pre-milling function

D.Multi-cylinder adjustment function

E.Profile tracking chamfer

F.Double color plastic pot

G.Dual guide afst head and tail function

H.PUR glue supply system

I.Four polishing function

J.Rapid sol system

K.Six-wheel press function

L.Pneumatic flat wipe function (floating edge)

Hot Searches