NaN / 0

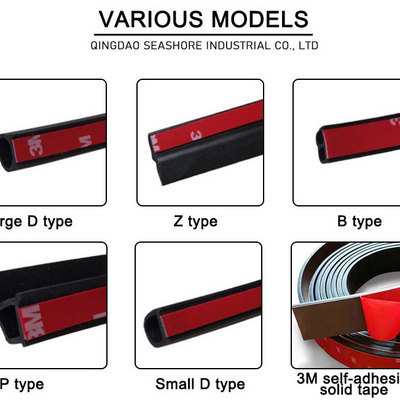

Self Adhesive automobile B Shape foam epdm Car Door Edge Trim with backed tape Rubber Seal protector Strip Weather stripping

Get Latest Price

US$ 1.8

≥100 Meters

US$ 1.2

≥10000 Meters

US$ 0.6

≥100000 Meters

Quick Details

Processing Service:

Cutting

Place of Origin:

Shandong, China

Brand Name:

SEASHORE

Model Number:

SH-01

Product Details

Self Adhesive automobile B Shape foam epdm Car Door Edge Trim with backed tape Rubber Seal protector Strip Weather stripping

Product Description

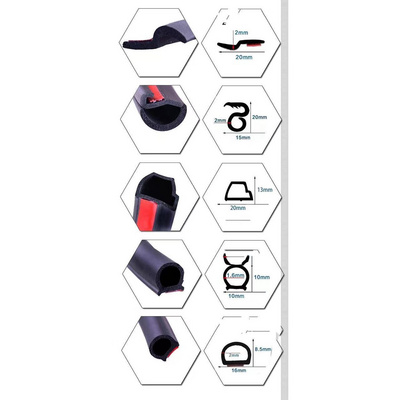

The self-adhesive foam rubber strip is made of a common material of EPDM. It is extruded in low or medium-density foam rubber. Different adhesive tapes on the back of the sponge rubber strip. EPDM rubber with many advantages. Such as excellent weather resistance, aging, ozone, chemicals, and good resistance to polar fluids such as acetone, methanol, etc. This rubber seal is applied to the car’s rear and front doors, for different types of cars. We provide custom shapes.

|

Material

|

sponge&foam EPDM rubber, neoprene, nitrile rubber

|

|

Color

|

Black, any other color is available

|

|

Hardness (Shore A)

|

25 ±5 as standard or per request

|

|

Specific gravity

|

0.5 to 0.7 g/cm³

|

|

Tensile strength

|

10MPA

|

|

Temperature Range

|

-40 °F – 248 °F (-40°C – 120°C)

|

|

Tolerance

|

RMA Standard Cross-sectional Tolerance E2, or per request

|

EPDM sealing strip

1. Seals and gaskets: EPDM rubber's weather resistance and chemical resistance make it suitable for manufacturing seals and gaskets in automotive, construction, and mechanical engineering.

2. Automotive components: EPDM rubber is extensively used in the automotive industry for manufacturing window seals, door trims, protective covers, rubber hoses, and other components.

3. Roofing and waterproofing materials: EPDM rubber's resistance to UV radiation and chemicals makes it suitable for roofing materials and building waterproofing membranes.

4. Cable insulation: EPDM rubber, being an excellent electrical insulator, is commonly used as insulation for cables and wires.These are just a few common advantages and applications of EPDM rubber.In reality, it finds widespread use in various other industries, such as industrial manufacturing, medical devices, and electronic equipment.

NBR rubber sealing strip

1. Seals and gaskets: Due to its excellent oil resistance and corrosion resistance, NBR material is widely used in the manufacturing of seals and gaskets for automotive, mechanical, engineering, and piping systems.

2. Automotive components: NBR material finds extensive application in the automotive industry for manufacturing fuel systems, braking systems, air conditioning systems, etc., including components such as oil seals, O-rings, and gaskets.

3. Industrial pipes and hoses: The oil resistance and corrosion resistance of NBR material make it an ideal choice for industrial pipes and hoses used for conveying petroleum, chemicals, lubricants, and other media.

4. Vibration isolation and cushioning materials: The elasticity and flexibility of NBR material make it suitable for manufacturing vibration isolation pads and cushioning pads, reducing the transmission of vibrations and impacts.These are just some common advantages and applications of NBR material.In reality, it finds widespread application in other fields such as aerospace, medical devices, and hydraulic systems, among others.

Silicone Rubber Sealing Strip

1. Encapsulation and sealing: Silicone material is widely used for encapsulation and sealing in electronics, optical devices, and electrical equipment, providing protection and insulation.

2. Medical devices: Due to its biocompatibility and high-temperature resistance, silicone material finds extensive application in medical devices, such as manufacturing surgical catheters, prosthetics, and medical seals.

3. Kitchenware and cooking utensils: The high-temperature resistance of silicone material makes it suitable for manufacturing kitchenware and cooking utensils, including baking pans, baking mats, and kitchen tool handles.

4. Automotive and aerospace: Silicone material is extensively used in the automotive and aerospace industries for manufacturing seals, thermal pads, soundproofing gaskets, cable protection sleeves, and more.

5. Construction and building materials: Silicone material can be used for construction sealing and themanufacturing of building materials, including glass curtain wall seals, waterproof coatings, insulation materials, etc.

Qingdao Seashore Industrial Co., Ltd is a joint-stock private enterprise that produces seal strips and seals for automobiles, doors and windows, construction machinery, ships, and rails. Since its establishment in 2000, it has been committed to the rubber and plastic sealing and shock absorption industry. The company’s main products include rubber, plastic extrusion seal strip and seals, door and window seals, automotive rubber seal strip, marine hatch seals, waterstop, rubber tubes, etc., and also provides sealing and vibration damping systems solutions for global customers.

Our Seashore company is headquartered in Licang District, Qingdao, and has a production base in Jimo District. The company has more than 100sets rubber and plastice equipments such as rubber extrusion lines, plastic extrusion lines, three (four) composite microwave vulcanization production lines, salt bath vulcanization production lines, steel edge rubber waterstop vulcanization production line etc. Our company’s R&D center is equipped with Mooney viscometer, rotorless vulcanizer, tensile testing machine, density tester, hardness tester, aging test chamber, ozone resistance test chamber, low-temperature brittleness tester Testing equipment such as test chambers and a complete set of chemical material analysis experimental instruments can conduct chemical analysis of purchased raw materials and test the performance of finished products.

FAQ

Q1: How soon can I get a precise quotation for custom rubber extrusion?

Please send us your inquiry by email or Alibaba TM message. Once we confirm the design (Feature details with parameters),material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.

Q4: What does your OEM service include?

We follow up your request from the design idea to the mass production.

1. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

2. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

3. You can also customize Logo on the product surface, package, color box or carton.

4. We also provide assembly service for the OEM parts.

Q5: What is your payment term?

A5: We accept T/T, Pay pal, Western Union, L/C, Alibaba Trade Assurance.

Hot Searches