NaN / 0

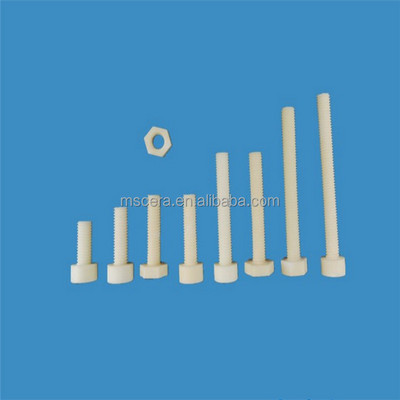

95 Ceramic Alumina Insulator Glazed Convex Porcelain Bead 15.2 Outer Diameter 6.5 x 10.9 Electrical Ceramics Glazed Porcelain

Get Latest Price

US$ 4

≥100 Pieces

US$ 3

≥5000 Pieces

Quick Details

Material:

Alumina Ceramic

Place of Origin:

Jiangsu, China

Brand Name:

Furuien

Product Details

Product Description

Alumina Ceramic

Aluminum oxide ceramics are divided into two types: high-purity type and ordinary type. The ordinary alumina ceramic system is divided into 99 ceramics, 95 ceramics, and other varieties according to the different Al2O3 content. Among them, 99 alumina ceramic materials are used to make high-temperature crucibles, refractory furnace tubes, and special wear-resistant materials,such as ceramic bearings, ceramic seals, and water valve plates; 95 alumina ceramics are mainly used as corrosion-resistant and wear-resistant components.

Advantages

1 High hardness

2 Excellent wear resistance

3 Corrosion resistance

4 High temperature resistance

2 Excellent wear resistance

3 Corrosion resistance

4 High temperature resistance

Product Paramenters

|

Properties

|

Units

|

Steatite Ceramic

|

Cordierite Ceramic

|

Mullite

Ceramic |

95%

Al2O3 |

99%

Al2O3 |

Zirconia

Ceramic |

Silicon

Nitride |

|

Colour

|

|

White

|

Yellow

|

White

|

White

|

Ivory

|

White

|

Grey

|

|

Density

|

g/cm3

|

2.7

|

1.9

|

2.6

|

3.5

|

3.85

|

6

|

3.2

|

|

Flexural Strength

|

Mpa

|

140

|

30

|

120

|

280

|

340

|

1150

|

600

|

|

Compressive Strength

|

MPa

|

900

|

350

|

500

|

2100

|

2200

|

2500

|

2500

|

|

Max Use Temperature

|

°C

|

1000

|

1200

|

1300

|

1400

|

1650

|

1500

|

1800

|

|

Thermal Condutivity

|

W(m.K)

|

2~3

|

1.3~1.8

|

2~6

|

16~28

|

19~30

|

2.5

|

20

|

|

Thermal Expansion Cofficient

|

10-6/°C

|

7 ~ 9

|

1.5~3.5

|

5~6

|

6.5~7.5

|

6~8

|

8~10

|

3~4

|

|

ThermalShock Resistance

|

△TC

|

100

|

300

|

150

|

140

|

150

|

250

|

600

|

|

Specific Heat

|

J/kg.K

|

850

|

800

|

900

|

950

|

950

|

500

|

500

|

|

Dielectric Strength

|

KV/mm

|

20

|

—

|

30

|

12

|

10

|

5

|

20

|

|

Dielectric Constant

|

Er

|

6

|

—

|

8

|

9

|

9

|

12

|

6

|

Hot Searches