NaN / 0

flow multifunctional water pump hydraulic control sus pressure reducing valve

Get Latest Price

US$ 52.65

≥1 Pieces

Quick Details

Port Size:

DN40-DN600

Warranty:

2 years

Place of Origin:

Anhui, China

Model Number:

JD745X-16Q

Product Details

Products Description

With the continuous development of modern high-rise buildings and the increasing demands of various users, our company combines the actual situation On the basis of the first generation hydraulic control valve, the second generation dual control room multifunctional hydraulic control valve has been successfully developed. It can automatically ensure the safe operation of the pipeline network according to different usage environments, even after one-time adjustment by previous users. The valve body adopts a streamlined design, all castings are treated with rust removal and spray painting, all moving parts are made of anti-corrosion materials, and all external conduits and guide valves are made of all copper or stainless steel materials. After assembly, the valve does not need to be painted again. All surfaces in contact with the medium have good corrosion resistance. By changing the connection form between the external guide valve and the conduit, it can be transformed into a water level control valve, a pressure reducing valve, a sound-absorbing/anti hammer/slow opening/slow closing check valve, a safety relief valve, an electric remote control valve, etc. According to the different media and pressure used, our company produces two types for users to choose from: piston type and diaphragm type. The main feature of this type of valve is to use the self pressure inside the pipeline to control the opening and closing of the main valve disc through the pressure difference between the upper and lower chamber control rooms, thereby achieving the goal.

Structural characteristics

1. It has a slow opening function, which can solve the traditional problem of manually closing valves and opening pumps

2. It has a slow closing function, and the closing time can be manually adjusted to automatically achieve slow closing and eliminate water hammer

3. It has good check function and uses rubber with good elasticity and high wear resistance as the sealing material, which can achieve no water leakage after closing.

4. The action is sensitive and there will be no loss of control.

5. No manual operation is required, and it operates automatically throughout the entire process of pipeline operation.

6. Convenient maintenance and repair, without the need to remove the entire valve from the pipeline. When repairing, identify the cause of the malfunction and only require partial maintenance.

7. The inside and outside of the valve, as well as all easily corroded parts, are treated with electrostatic spraying, which will not rust when used in sewage for a long time.

8. The performance remains unchanged when installed in a neutral or horizontal position in the pipeline.

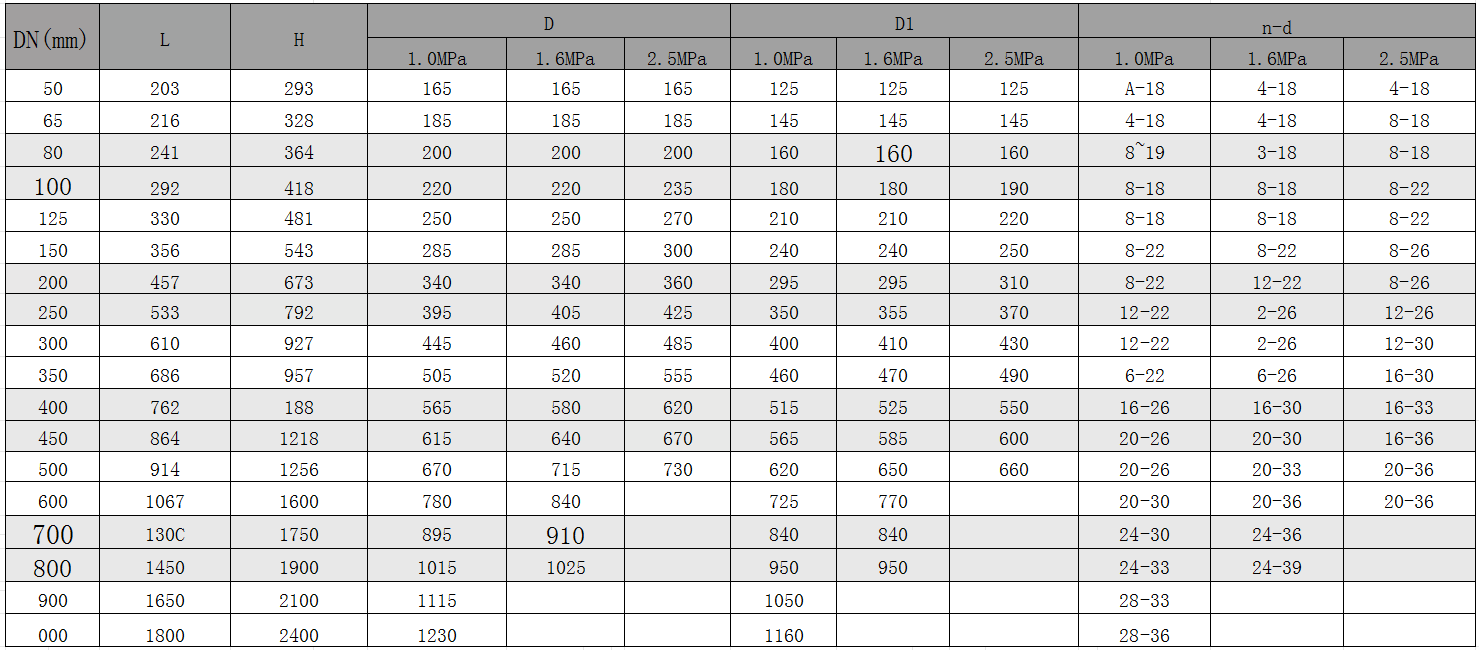

Technical parameter

Application Area

Factory Show

Hot Searches