NaN / 0

Wholesale Cheap T-shaped Aluminum Roof Sheet Panels for Factory Wall Construction

Get Latest Price

US$ 580 - 650

Min.Order: 5 Tons

Quick Details

Model NO:

JFHJ

Transport Package:

Carton

Origin:

Zhejiang China

Material:

AluminumMetal

Product Details

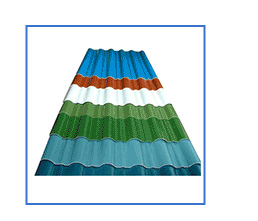

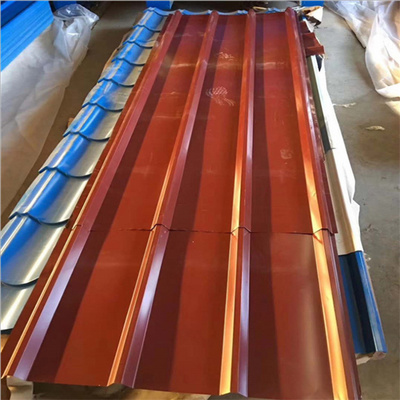

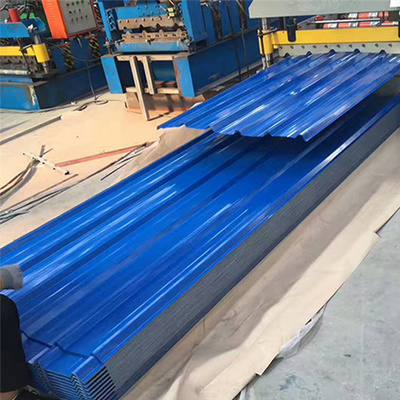

Corrugated Roofing Sheets Description

Product Description:

Our color coated steel roofing sheets are designed to provide long-lasting performance and aesthetic appeal for your roofing needs. Made from high-quality steel and coated with a protective layer of color, these sheets offer superior strength, durability, and corrosion resistance.

Key Features:

- Versatile Applications: Suitable for a wide range of roofing projects, including residential, commercial, industrial, and agricultural buildings.

- Superior Strength: The corrugated design provides enhanced structural integrity, withstanding heavy loads and extreme weather conditions.

- Long-Lasting Protection: The color coating safeguards the sheets against rust, corrosion, and fading, extending their lifespan and reducing maintenance costs.

- Excellent Weather Resistance: Impenetrable to water and moisture, effectively preventing leaks and protecting your interiors from the elements.

- Lightweight and Easy to Install: The sheets are lightweight, simplifying installation and reducing the overall weight on your building structure.

- Customizable Options: Available in various colors, thicknesses, and lengths to meet your specific project requirements.

Processing Services:

We offer a range of processing services to customize your color coated steel roofing sheets, including:

- Welding: Joining sheets together to create larger panels or complex roof structures.

- Punching: Creating holes for fasteners, ventilation, or other purposes.

- Cutting: Precisely tailoring sheets to specific dimensions for a perfect fit.

- Bending: Shaping sheets to meet architectural requirements or curved roof designs.

- Decoiling: Straightening and uncoiling sheets for easy handling and installation.

Technical Specifications:

- Product Name: Color Coated Steel Roofing Sheet

- Tolerance: ±1%

- Keyword: PPGI Corrugated Plate

- Type: Wave Tile

- Surface Treatment: Color Painted

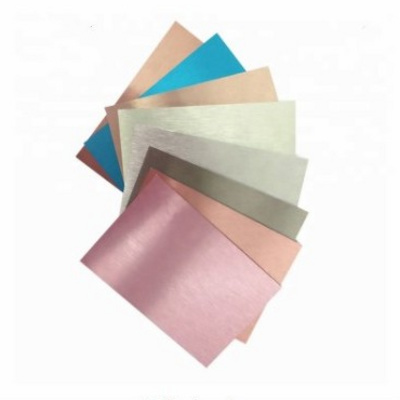

- Color: Customized

- Shape: Corrugated Wave

- Packing: Standard Seaworthy Package

- Material: ASTM/AISI/SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+Z Q195-q345

- Length: 1400-1799mm, 1800-2000mm, 2001-3600mm, 3601-3660mm, Customization

Contact us today to learn more about our color coated steel roofing sheets and discuss your specific project requirements.

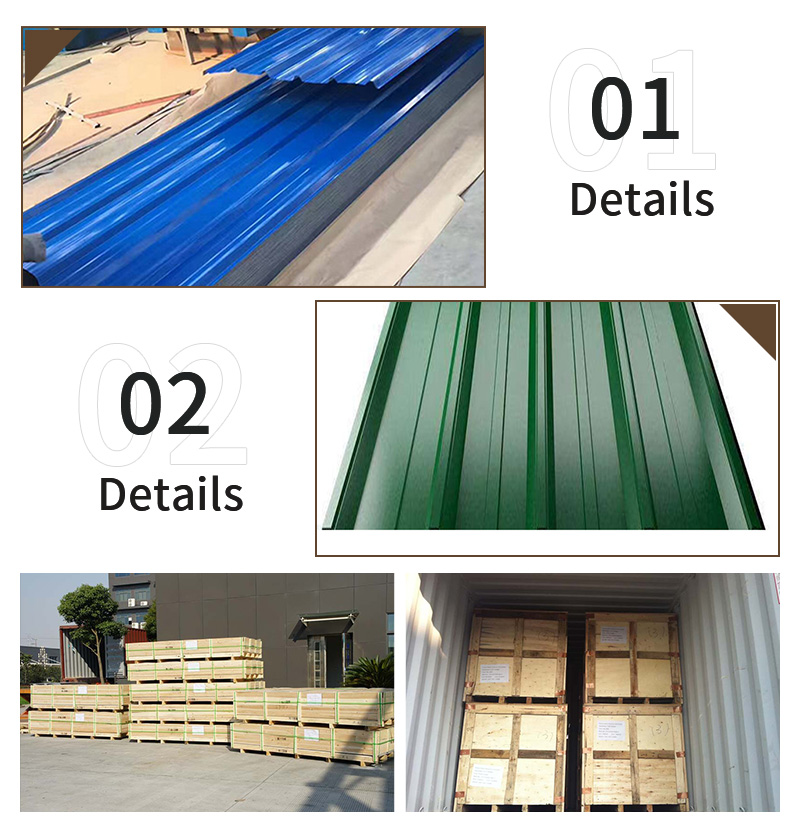

Corrugated Roofing Sheets Detail Show And Packing

Corrugated metal sheets are also called color steel plates, which are rich in color and easy to construct. There are many colors of prepainted tiles, you can contact us at any time to choose the style you need.

Corrugated Roofing Sheets Application

Fence:

Corrugated panel is used a lot as fencing panel due to its durable and long lasting features. As every one need their fence that can be used for long time and with low maintenance cost . The corrugated metal panel will easily stand up even under tough environment, can meet the requirement where rain a lot and get a lot of wind.

Roof:

Due to anti-siphon groove , some of corrugated metal sheets can help protect against leaks for a lifetime , they are considered as perfect choice for many types of applications. Including siding , roofing and decking , thanks to its exposed fastener , which make it easy to install . In addition , the long lines also create an aesthetically pleasing appearance in modern building application.

Corrugated Roofing Sheets Production Process

1.Raw Materials:

The first step is to convert raw material into your needed form. Usually the raw materials will be aluminum, zinc , copper and also stainless steel. So firstly need to purify and melt raw materials down to form the metal coil.

2.Coatings:

Put the coil into the coil coater , and then coat it. The substance is placed on a continous coating line where it is cleaned and specially treated with paint and baked at a high temperature. At the end of each coating of paint , then it will be checked for quality assurance.

3.Roller former:

The coated metal coil will enter the roller press , the roller former is an important equipment that turn metal coil into metal sheets and panels. In this step our purpose is to reduce tits thickness and achieve the desired grade. Then the shape and bend we desired will be formed by the successive roll of roller.

4.Computer control unit:

Then it comes to the computer control, the computer control unit will make changes in speed,control,operation and panel length.The engineers will adust roller machine and cutting of panel into a specific length.

5.Post -process:

The remnants are collected, bundled, and sold back to the mill to and re-used as metal coils. These scraps are re-used in the manufacturing process continuously for better results.

Our Service

| Pre-sales Service 1.Keep in touch with you closely, keep you posted for all the line of your goods. 2.Do our best to cooperate with you from the enquiry to order to the shipment arrangement. |

After-Sales Service 1.Supply competitive price and heart to heart service for our customer. |  |

Shipping&Payment

FAQ

1.What types of building materials do you supply?

Answer: We offer a wide range of building materials, including but not limited to steel, glass, tiles, roofing materials,and insulation.

2.Can I request product samples before placing a bulk order?

Answer: Yes, we encourage clients to request samples to assess the quality, specifications, and suitability of our building materials for their projects.

3.What is the minimum order quantity (MOQ) for your building materials?

Answer: The MOQ varies depending on the type of building material and specific product. Please contact our sales team for detailed information about MOQs.

4.Are your building materials compliant with international standards?

Answer: Yes, our building materials comply with relevant international standards and certifications. We can provide documentation upon request.

5.Can you customize building materials to meet specific project requirements?

Answer: Yes, we offer customization options for certain building materials. Contact our sales team to discuss your specific requirements and customization possibilities.

6.What is your lead time for production and delivery?

Answer: Production and delivery times depend on the type and quantity of building materials ordered. We provide estimated timelines upon order confirmation.