NaN / 0

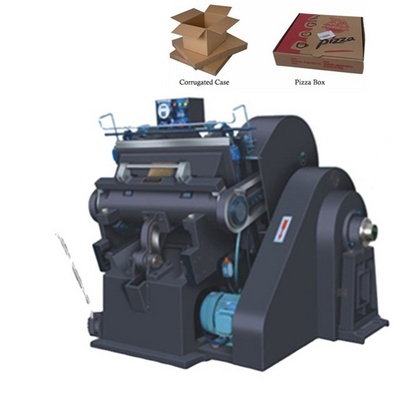

manual corrugated board die cutting and creasing machine /carton box making machine

Get Latest Price

US$ 6500

≥1 Sets

US$ 6400

≥2 Sets

Quick Details

Type:

Die-cutting Machine

Production Capacity:

30 m/min

Max. workable width:

1100mm

Place of Origin:

Hebei, China

Product Details

manual corrugated die cutter & creasing machine /

Product Description

Application

This series of die cutting and cresting machines are special equipments for die cutting and creasing a wide range of materials, such as cardboard, corrugated board, plastic and leather. They are applicable to the fields of printing, packaging, decoration industries.

This machine has four insurance, four function . I nsurance: Longmen insurance, Triangle insurance , Handle insurance , light-operated automatic insurance, This is more safe and reliable . F action: single cut, delay, continuation, numeration.

Another , brak ing clutch is electric chuck braking clutch, the feature are the sensitive brake, big insurance factor, strong safety performance, etc . The adjustable plate frame space template for upper, unloading board. And with standard: manual oil supply, concentration of oil supply or computer automatic injection allocation. We can manufacture variable frequency speed regulation

Structural Features

Sliding bearings are made of high quality alloy copper, thus to get effect of anti-friction and shake reduction .

High strength for one piece casing by using top-ranking material for machine body

With function of single, continuous cutting and opening delay operation, delay range is adjustable.

Safety system is reliable

Flywheel is with big moment of forth and large pressure.

Single plate electromagnetic clutch is sensitive and reliable

Operating position is reasonably arranged, moving-bed can be opened to its optimum

Standard configuration: manual oil-supplying device

Function: single cutting, time delay, continuous, numeration

Parameter

|

Model |

Max, Rule Area |

Working speed |

Creasing cutting length |

Motor |

Overall Dimensions(L×W×H) |

|

ML750 |

750×520mm |

28±2(strokes/min) |

< 15m |

2.2Kw |

1260*1350*1280 |

|

ML930 |

930*670 mm |

23±2(strokes/min) |

<25m |

4.0Kw |

1800*1350*1280 |

|

ML1100 |

1100 × 800mm |

20±2(strokes/min) |

< 30m |

5.5kw |

1900×1780×1700mm |

|

ML1200 |

1200×830mm |

20±2 |

< 35m |

5.5kw |

1920×2000×1800mm |

|

ML1300 |

1300×920mm |

18±2 |

< 40m |

5.5kw |

2000×2400×2000mm |

|

ML1400 |

1400×1000mm |

18±2 |

< 45m |

5.5kw |

2100×2400×1930mm |

|

ML1500 |

1500×1050m m |

18±2 |

< 45m |

5.5kw |

2100×2400×1930mm |

|

ML1600 |

1600×1250mm |

16±2 |

< 50m |

11kw |

2170×2560×2230mm |

|

ML1800 |

1800×1300mm |

16±2 |

< 62m |

15kw |

2240×2800×2130mm |

Wallboards and base: casting HT200, place of origin: Hebei

Electric Appliances: CHINT

Bearings: produced in Harbin, Luoyang or Wafangdian

The machine adopts chain transmission.

Motor: Hengshui Mengniu

Note: (equipped with vulnerable parts)

Payment terms:

30%T/T in advance, 70% before leaving factory.

Delivery:

Packaging Details: PE film and container

Delivery Detail: W ithin 30 workdays after receiving 30% advanced deposit

Notice:

1. Supervision of Erection: Buyers can be supervised before delivery

2. Startup and Guarantee Tests: Engineers available to service machinery overseas ,we have engineer to help with installation, the technician from seller will train the worker of buyer for operation of equipment, daily maintain, and have general technical training

3.After Sales Service: Supplier will assign technicians to coach installation and debugging, client will pay the piper round-trip, accommodation .

4. W arranty: one year

5. CE and ISO certificates

Certifications

Hot Searches