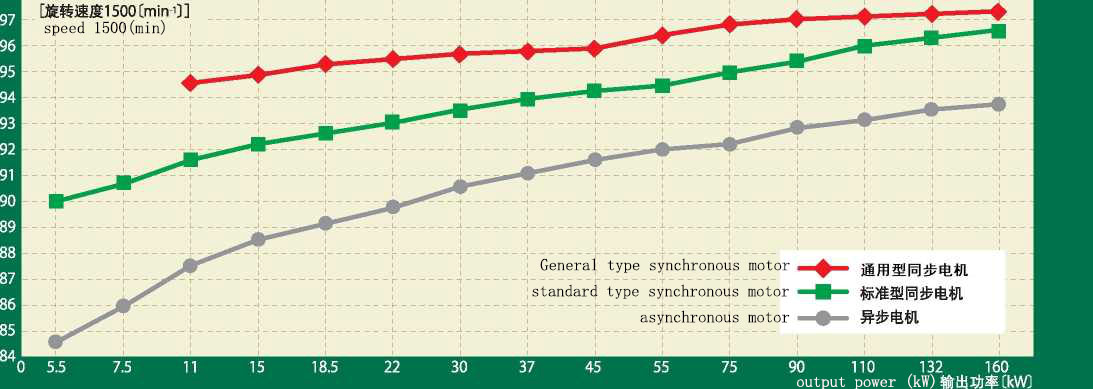

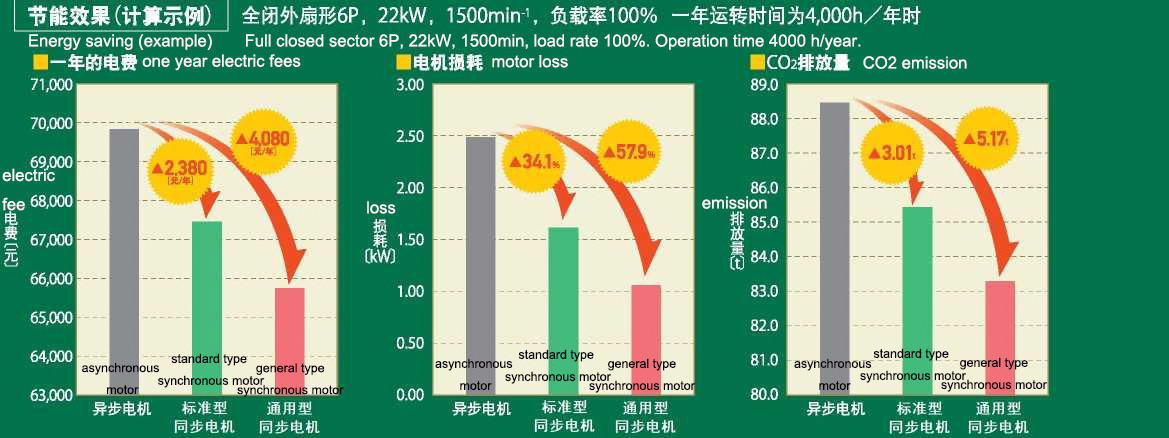

More energy saved by combined operation

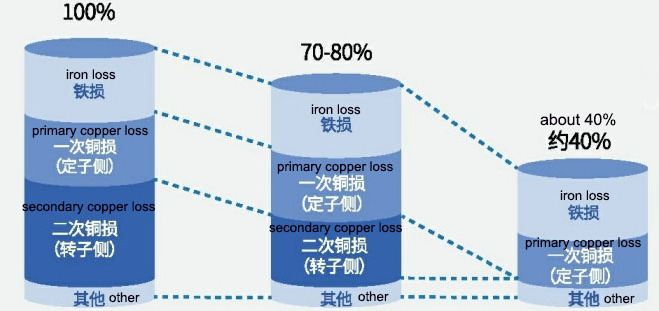

By combining the synchronous motor with an independent frequency converter for energy-saving control, the power loss can be reduced and further high efficiency operation can be realized.