NaN / 0

Custom Liquid Detergent Making Machine Cosmetic Lotion Shampoo Liquid Soap Making Machine Blending Tank Mixing

Get Latest Price

US$ 2000

≥1 Sets

US$ 1850

≥3 Sets

Quick Details

Barrel Volume (L):

20000

Max. Loading Volume (L):

5000 L

Range of Spindle Speed(r.p.m):

50 - 70 r.p.m

Weight (KG):

500 KG

Product Details

Product Description

customisation Liquid Detergent Making Machine Cosmetic Lotion Shampoo Liquid Soap Making Machine Blending Tank Mixing

|

Profile/type

|

Single layer tank

|

Double layer tank

|

Three layer tank

|

|||

|

Material

|

SS304 or SS316L

|

|

|

|||

|

Volume

|

100L-30000L (Customized)

|

|

|

|||

|

Tank Type

|

Vertical type/Horizontal type/Mobile type

|

|

|

|||

|

Structure

|

One layer

|

Inner layer+jacket

|

Inner layer+jacket+insulation

|

|||

|

Heating way

|

Electric/Steam Heating

|

|

|

|||

|

Interior finish surface

|

Mirror polished Ra<0.4um

|

|

|

|||

|

Outside surface

|

2B or Satin Finish

|

|

|

|||

|

Stirrer type

|

Impeller, Anchor , Turbine , High shear, magnetic mixer, Anchor mixer with scraper

|

|

|

|||

|

|

|

|

|

|||

|

Power

|

0.55~55KW

|

|

|

|||

|

Voltage

|

110V~480V

|

|

|

|||

|

Top Head type

|

Dish top, Open lid top, Flat top

|

|

|

|||

|

Bottom type

|

Dish bottom, Conical bottom, Flat bottom

|

|

|

|||

|

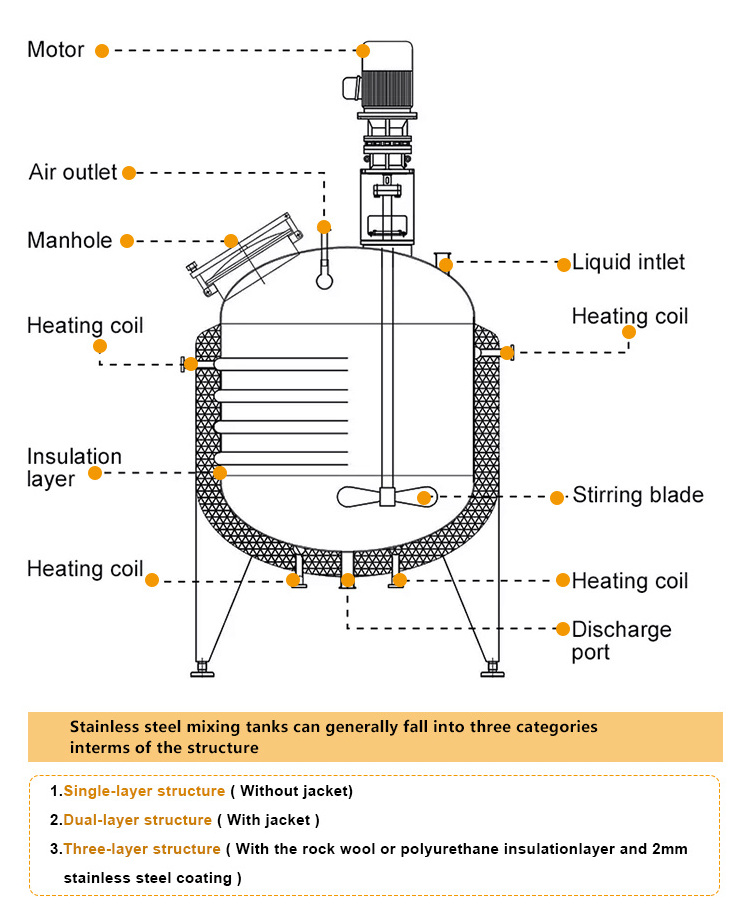

Parts Details

|

1.Quick open manhole / Pressure manhole 2.Various types of CIP cleaners 3.Sterile respirator 4.Adjustable Legs 5.Inlet and Outlet sanitary valve 6.Thermometer (According to customer requirements ) 7.Paddle blender .(According to customer requirements) 8.Liquid level meter and lever controller (According to customer requirements) 9.Ladder

|

|

|

|||

|

We can customize the mixing equipment according to customer requirements.

|

|

|

|

|||

OEM/ODM

application

Product details

Main Features

1) Full of SUS304, contact materials parts SUS316L, GMP standard.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Double jackets and insulation provide electric heating or steam heating.

4) High effection mixer and homogenizer emulsion products 2μm.

5) Apply to cosmetics, shampoo, liquid soap, detergent, dish washing etc products.

1) Full of SUS304, contact materials parts SUS316L, GMP standard.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Double jackets and insulation provide electric heating or steam heating.

4) High effection mixer and homogenizer emulsion products 2μm.

5) Apply to cosmetics, shampoo, liquid soap, detergent, dish washing etc products.

Product Photograph

Related products

About us

Henan Zhongyilong machinery is a high-tech manufacturing enterprise focusing on automatic packaging production equipment for food, beverage, water. We can customize beverage production line process and formula according to customer's demand. Our company have been specializing in food&beverage processing line for over many years and successfully set up 300 factories for demestic and international customers. People all over the world consume products packaged by Zhongyilong machinery solutions every day. Each of those packaging solutions is developed according to our goal to deliver the highest quality standards to consumers. We are a leading provider of equipment, services and complete solutions for packaging liquids, foods, home and personal care products in

PET, can, glass and other materials. Zhongyilong machinery is the A to Z turnkey plant provider,We are committed to our customers success. When you partner with us , you can be sure of solutions that optimise your product packaging, boost line performance and help you grow your business. we lead the market in the field of liquid bottling ,blow molding,labeling,packing machinery and process technology for water,juice,carbonated drinks,edible oil,dairy and daily care products etc.We can provide fully automatic or economic solution for every customer. We provide one-stop service to help customers build food and beverage plants: process formula, plant guidance equipment selection, installation and commissioning, technical training, after-sales service.

PET, can, glass and other materials. Zhongyilong machinery is the A to Z turnkey plant provider,We are committed to our customers success. When you partner with us , you can be sure of solutions that optimise your product packaging, boost line performance and help you grow your business. we lead the market in the field of liquid bottling ,blow molding,labeling,packing machinery and process technology for water,juice,carbonated drinks,edible oil,dairy and daily care products etc.We can provide fully automatic or economic solution for every customer. We provide one-stop service to help customers build food and beverage plants: process formula, plant guidance equipment selection, installation and commissioning, technical training, after-sales service.

We look forward to your inquiry and exchange cooperation. Welcome to inquire and visit our factory

FAQ

Q1: Where is your factory? How can I visit your factory?

A: Our factory is located in Henan Province. If you have a travel plan, we warmly welcome you to visit our factory

Q2: Can you send me a video to show me how the machine works?

A: Of course, we made videos of each machine

Q3: How do I know your machine is designed for my product?

A: You can send us your product samples, and we will test them on the machine

Q4: How do I pay for my order?

Answer: Usually we accept L/C, D/A, D/P, T/T, Western Union, MoneyGram and cash payment

Q5: Do you have a Ce certificate?

A: For each model of machine, it has CE certification