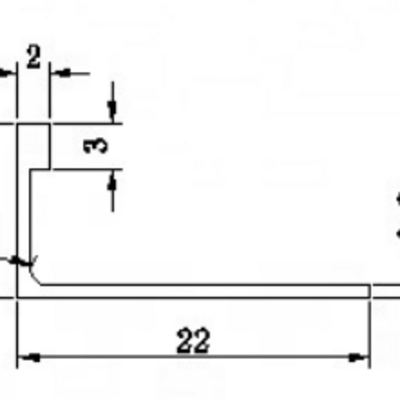

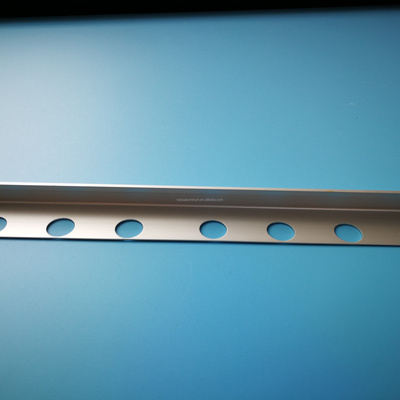

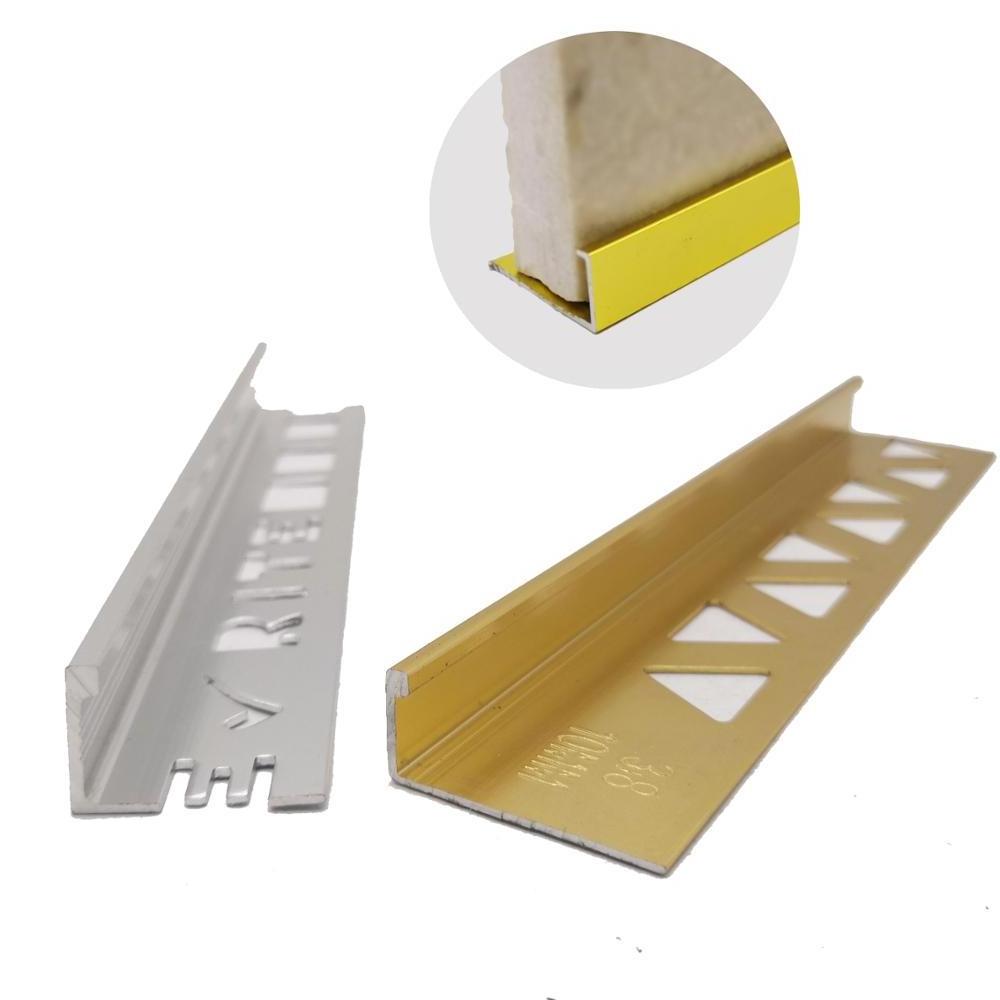

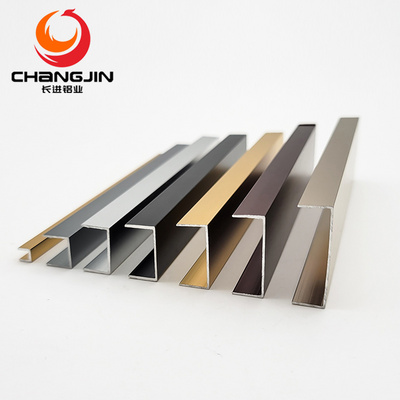

Extruded different shape and size Aluminum profile.

Use Primary aluminum to produce.

Special alloy: 6005. 6061. 6082. 7005.7075

Total have 12 Unit Aluminum extruded Line.