NaN / 0

Wholesale Lug Type Knife Gate Valve Dn100 Cast Steel WCB Flanged Manual Slurry Knife Gate Valve

Get Latest Price

US$ 199

≥1 Sets

US$ 19

≥100 Sets

Quick Details

Port Size:

DN50-DN1200mm

Warranty:

1 year

Place of Origin:

Jiangsu, China

Model Number:

PZ43W-10P

Product Details

Product Description

|

Material of main parts

|

|

|

|

|

||||

|

Valve body and bonnet: stainless steel, carbon steel, gray cast iron

|

|

|

|

|

||||

|

Valve seat: carbon steel, stainless steel

|

|

|

|

|

||||

|

Stem: stainless steel

|

|

|

|

|

||||

|

Sealing surface:Rubber, PTFE, stainless steel, cemented carbide

|

|

|

|

|

||||

Knife gate valve:

there are plate gate valve, knife mud gate valve, knife slag discharge gate valve and single clip slag mud gate valve

And manual single clip knife gate valve.

Type of gate valve: according to the configuration of sealing surface, it can be divided into wedge gate valve and parallel gate valve.

Wedge gate valve can be divided into: single gate pole type, double gate plate type and elastic gate type.

Parallel gate valves can be divided into single gate plate and double gate plate.

According to the thread position of the valve stem, it can be divided into rising stem gate valve and Non rising stem gate valve.

Structural features:

The valve has the advantages of light switch, reliable seal, good elastic memory and long service life. It can be widely used in tap water, sewage, construction, petroleum, chemical industry, food, medicine, light textile, electric power, shipbuilding, metallurgy, energy systems and other body pipelines as regulating and intercepting devices.

Characteristics of knife gate valve:

1. The ultra short structure length saves materials and greatly reduces the overall weight of the pipeline system.

2. It takes up less effective space, can effectively support the strength of the pipeline, and can reduce the possibility of pipeline vibration.

3. The ram is made of austenitic stainless steel, with greatly improved corrosion resistance, which can effectively prevent seal leakage caused by ram corrosion.

4. The upper sealing packing adopts flexible PTFE, which has reliable sealing and light and flexible operation.

5. The ram has the function of knife switch, which can effectively cut off all kinds of sundries in the medium.

6. If the valve disc is made of hard sealed stainless steel and spray welded, the requirements for temperature and pressure of the valve can be well expanded.

Advantages of gate valve:

1. The fluid resistance is small, and the sealing surface is less scoured and eroded by the medium.

2. Opening and closing is labor-saving.

3. The flow direction of the medium is unrestricted, without disturbing the flow and reducing the pressure.

4. Durable and easy to use.

5. Simple shape, short structural length and wide application range.

Disadvantages of gate valve:

1. It is easy to cause erosion and abrasion between the sealing surfaces, and it is difficult to maintain.

2. The overall size is large, which requires a certain space for opening and closing, and the opening and closing time is long.

3. The structure is complex.

Main specifications and performance:

1. Nominal pressure (MPA) shell test (MPA) seal test (MPA)

1.0 1.6 1.5 2.4 1.1 1.8

2. Working temperature

≤ 900 ℃

3. Applicable medium:

pulp, sewage, coal slurry, ash, slag water mixture

4. Main parts:

sealing surface of valve rod of cutting body and cutting cover RAM

5. Materials:

stainless steel, carbon steel, gray cast iron, carbon steel, stainless steel, stainless

steel rubber,

tetrafluorocarbon, stainless steel, cemented carbide, etc

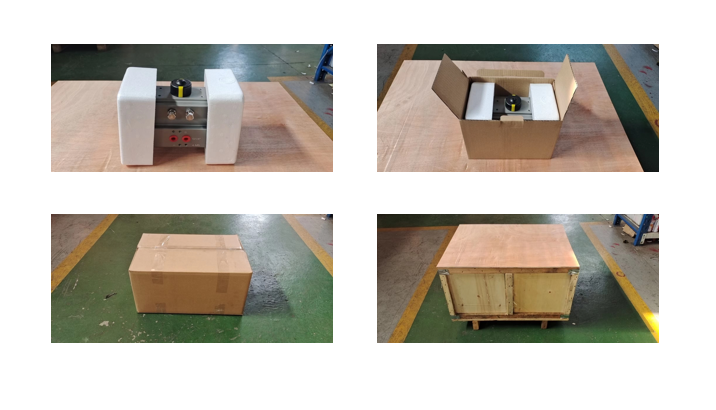

Packing & Delivery

Hot Searches