NaN / 0

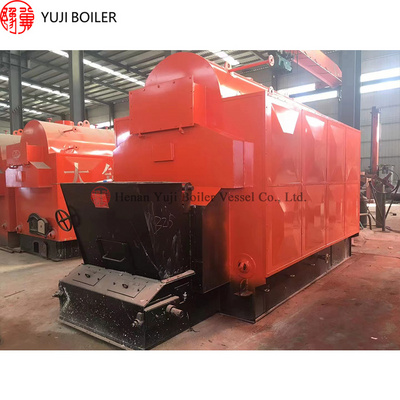

Fully Automatic Chain Grate Stoker Coal Fired Steam Boiler Supplier

Get Latest Price

US$ 5000

≥1 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

YUTONG

Dimension(L*W*H):

6000*2500*3400

Weight:

20ton

Product Details

Fully Automatic Chain Grate Stoker Coal Fired Steam Boiler Supplier

Product Description

|

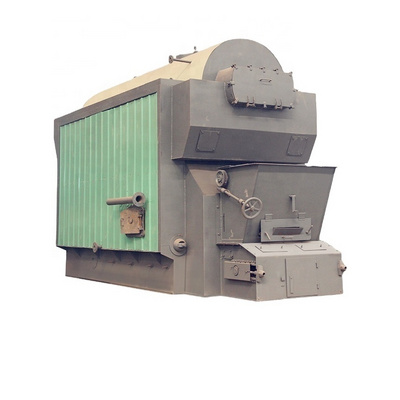

DZL Coal Biomass Fired Steam Boiler

Capacity: 0.5t/h-30t/h ¦ 0.7-5.6 MW

Pressure: 0.7Mpa-3.8Mpa

Fuel: Coal or Biomass

Structure:Water Fire Tube and Chain Grate Stoker

Application: Chemical industry, textile plant, rice mill, garment factory, livestock, farm, hotel, school, etc. |

|

Introduction of Fully Automatic Chain Grate Stoker Coal Fired Steam Boiler Supplier

| Sitong DZL seires coal/biomass fired steam boiler realizes almost zero pollution with the use of special dust collector solution (bag dust collector, double towers desulfurization, etc.), it is honored as Chinese famous brand. This series boiler is single drum horizontal type shell boiler, the combustion equipment is chain grate (small scale flaker is available), has the advantages of feed mechanically and strong adaptability of different fuels. The fuel could be II class bituminous coal, the diameter should be 6-25mm, and ash content should be less than 32.4%. Otherwise, DZL series boiler could also burn biomass fuel, including wood, straw, bagasse, rice husk, coconut shell, cotton seeds, peanut shell, etc. |

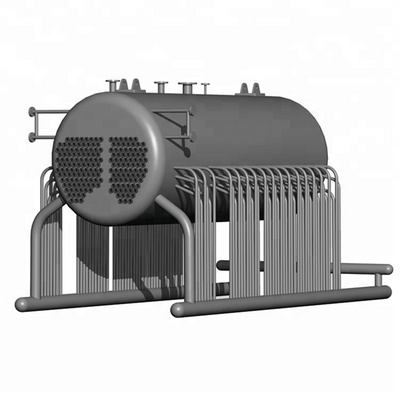

Features of Fully Automatic Chain Grate Stoker Coal Fired Steam Boiler Supplier

|

Advanced Design and Configuration |

Function / Advantage |

|

New Dust Collection |

Achieve almost zero pollution |

|

Smoke and Dust Separation Chamber |

Decrease the original emission concentration of smoke |

|

Splayed Wall |

Has the function of dust suppression, protect environment |

|

Small Scale Flaker Type Grate |

New metallurgy formulate make the grate withstand high temperature more than 1600 ℃, make sure running without stop even when repair . |

|

Spirally Corrugated Tube |

Improve heat transfer coefficient, thermal efficiency increase to 83%. |

|

Airfoil Shaped Flue |

Decrease the flue gas temperature in the area of high temperature tube plate, prevent tube plate cracking and swell. |

|

Spark R etaining W all in Furnace |

I mprove the combustion efficiency. |

|

New Type Furnace Arch |

Strength combustion, improve the adaptability of different coal types, and improve combustion efficiency |

|

Header Backwater Ejection |

Avoid water wall tube crack |

|

Large Heating Area |

Make sure excess output |

Technique Parameters

|

Model

|

DZL1-0.7-AII

|

DZL2-0.7-AII

|

DZL4-1.25-AII

|

DZL6-1.25-AII

|

DZL8-1.25-AII

|

DZL10-1.25

|

DZL15-1.6

|

DZL20-1.6

|

|

Rated evaporation

|

1 |

2 |

4 |

6 |

8 |

10 |

15 |

20 |

|

Working

|

0.7/1.0/1.25 |

0.7/1.0/1.25 |

1.25/1.6 |

1.25/1.6 |

1.25/1.6 |

1.25/1.6 |

1.6/2.5 |

1.6/2.5 |

|

Rated steam

|

170/184/194 |

170/184/194 |

194/204 |

194/204 |

194/204 |

194/204 |

204/226 |

204/226 |

|

Feed water

|

20 |

20 |

20 |

20 |

20 |

70 |

70 |

70 |

|

Effective area of

|

2.22 |

2.22 |

4.1 |

5.85 |

7.95 |

9.75 |

11.1 |

23.9 |

|

Fuel consumption

|

151 |

302 |

600 |

880 |

1150 |

1450 |

2200 |

1160 |

|

Exhaust flue gas

|

150 |

150 |

150 |

150 |

150 |

150 |

125 |

1265 |

|

Thermal Efficiency

|

82 |

82 |

82 |

82 |

82 |

82 |

83 |

83 |

|

Size(m) |

5.1x 2.2x 3.0 |

5.5x 2.3x 3.3 |

6.6x 2.6x 3.6 |

8.1x 2.9x 3.8 |

8.1x 3.1x 3.8 |

7.7x 3.2x 3.6

|

10x 3.24x 3.54

|

11x 3.24x 3.54

|

|

Weight (t) |

17 |

23 |

25 |

35 |

45 |

33

|

42

|

50

|