NaN / 0

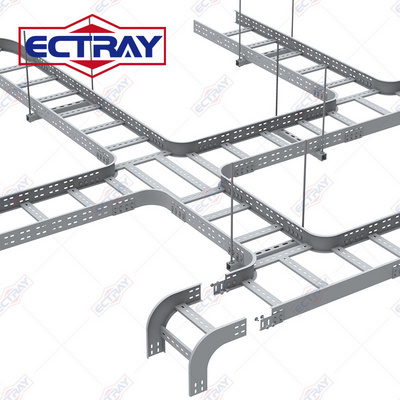

Galvanized Cable Ladder, ladder cable tray, Ladder Type Cable Tray

Get Latest Price

US$ 1

≥1 Meters

Quick Details

Type:

Ladder Tray

Material:

Steel

Width:

100-1200mm

Length:

3000/6000mm

Product Details

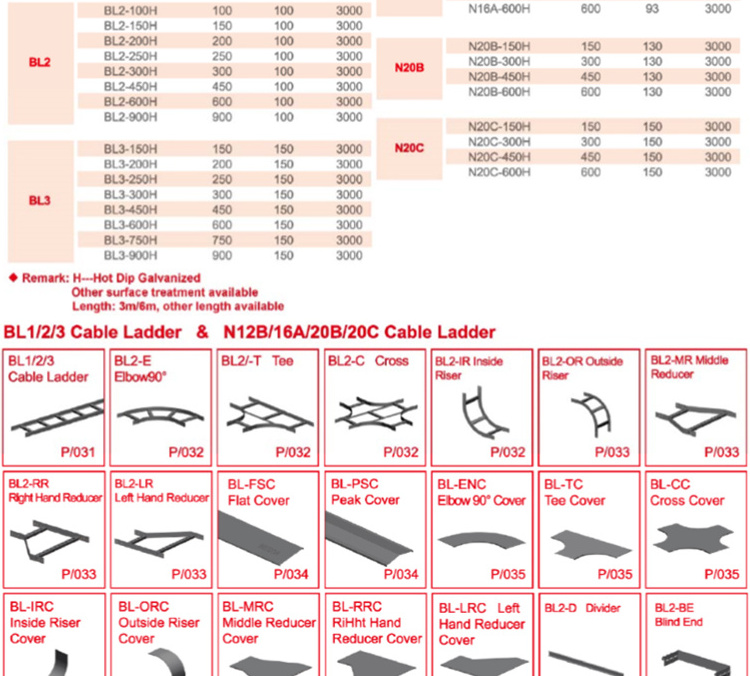

Cable Ladder Detailed Specification:

4. Cable Ladder Tray Provides Electro Galvanized cable tray ladder manufacturer

a. Solid side rail protection and system strength with smooth radius fittings and a wide selection of materials and finishes.

b. maximum strength for long span applications standard widths of 6,12,18, 24, 30, and 36 inches

c. standard depths of 3, 4, 5, and 6 inches

d. standard lengths of 10, 12, 20 and 24 feet

e. rung spacing of 6, 9, 12, and 18 inches

Ladder cable tray is generally used in applications with intermediate to long support spans 12 feet to 30 feet.

Advantage of cable tray ladder :

♦ Full free air rating of cables, results in smaller conductors vs. conduit

♦ Greater fill volume allowed, results in less space

♦ Used in all locations except elevatorshafts (the only prohibition on cable tray use)

♦ Used as an equipment grounding conductor

♦ Less stress on cables during installation and operation

♦ Increased safety, no moisture condensation problems nor transmission of corrosive or explosive gases, as with conduit

♦ Simplified maintenance with the flexibility of adding or changing circuits

♦ Simplified engineering and construction. Add, change, modify more easily

♦ Used with other wiring methods

♦ Longer support spans up to 55'

CABLE LADDER Surface Finish:

♥ Hot dip galvanized

♥ Pre galvanized

♥ Aluminum Alloy

♥ Stainless steel

♥ Epoxy Coated

♥ Polyester coated

When metal ladder cable trays came of age, they were used to support the new armored shielded power cables that were permitted outside the conduit environment. Utilities and industrial companies initiated the use of expanded metal and solid trough-styled trays for supporting power and control cable.

Cable trays quickly proved their worth as a safe, dependable and cost-effective solution to routing and supporting cables. Installed cost savings of over 50% on project after project drove the market for metal cable trays to over 80 million dollars.

Cable Tray is NOT A WIREWAY and is viewed as a support for cables. This provides the designer and user ma ny benefits.

cable tray ladder specification:

| Model No. | Width | Height | Rung Space | Length | Thickness |

| BLC1505015 | 150 | 50 | 300 | 3000 | 1.5 |

| BLC2005015 | 200 | 50 | 300 | 3000 | 1.5 |

| BLC1507515 | 150 | 75 | 300 | 3000 | 1.5 |

| BLC2007515 | 200 | 75 | 300 | 3000 | 1.5 |

| BLC1501002 | 150 | 100 | 300 | 3000 | 2.0 |

| BLC2001002 | 200 | 100 | 300 | 3000 | 2.0 |

| BLC2001252 | 200 | 125 | 300 | 3000 | 2.0 |

| BLC2501252 | 250 | 125 | 300 | 3000 | 2.0 |

| BLC2001502 | 200 | 150 | 300 | 3000 | 2.0 |

| BLC2501502 | 250 | 150 | 300 | 3000 | 2.0 |

| BLC10001502 | 1000 | 150 | 300 | 3000 | 2.0 |