NaN / 0

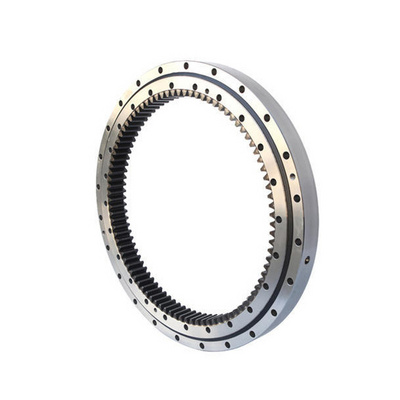

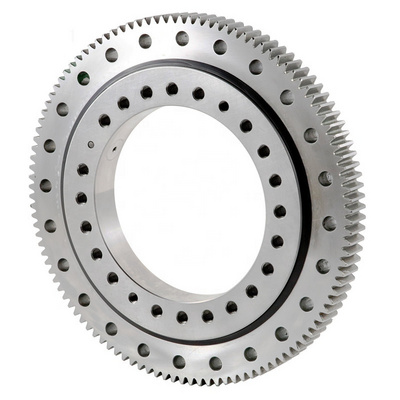

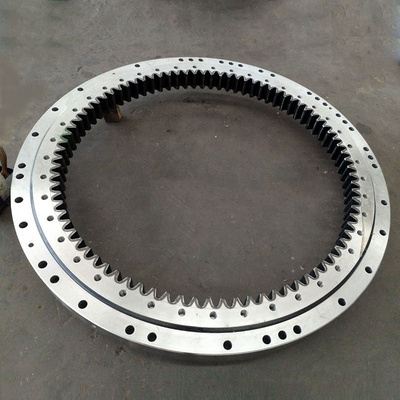

PC220 20Y-25-22200 Replacement Slewing Bearing Ring Turntable Swing Bearing For Excavator or crane

Get Latest Price

US$ 400

≥2 Pieces

Quick Details

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Other

Feature:

Four Point Contact

Seals Type:

According to the model

Brand Name:

LYJW

Product Details

Product Description

LYJW slewing bearings can be divided into single-row four-point contact ball slewing bearings, single-row cross roller slewing bearings, double-row different ball diameter slewing bearings, three-row cylindrical roller slewing bearings and ball combined slewing bearings according to their structure. The product diameter ranges from 100-15000 mm.

This type of bearing can be divided into no-gear bearings, external gear bearings and internal gear bearings.

The bearings we produce have the characteristics of reasonable design, light weight, high carrying capacity, and wide application range.

This type of bearing can be divided into no-gear bearings, external gear bearings and internal gear bearings.

The bearings we produce have the characteristics of reasonable design, light weight, high carrying capacity, and wide application range.

|

Cooperative Brands

|

Excavator Model

|

|

1

|

CAT70B CAT120B CAT215 CAT311 CAT305.5 CAT306 E307 E70 E120 CAT308 CAT311 CAT312 CAT315 CAT320 CAT323 CAT324 CAT325 CAT326 CAT330 CAT336 CAT345 CAT349 CAT365 CAT374 CAT385 CAT390 ect.

|

|

2

|

PC30 PC45 PC50 PC55 PC56 PC60-5-6-7 PC60-8 PC70-8 PC78 PC100-3 PC120-6 PC130-7 PC150 PC160 PC200-7/8 PC220 PC228 PC270 PC240 PC300-6/7 PC360 PC400-6/7/8 PC450-6 PC600-6 PC650-3 PC650 PC800 PC1000 PC1200 PC1250 ect.

|

|

3

|

UH025 UH045 UH063 UH083 EX35 EX40 EX55 EX60 EX60-3 EX120 EX200 EX300 EX310 ZX60 ZX70 ZA80 ZX110 ZX120 ZX200 ZX210 ZX240 ZAX250 ZAX270 ZX290 ZX330 ZX470 ZX870 EX300 EX310 EX1000 EX1200 ZX225UR ZX520 ZX870ect.

|

|

4

|

SK35 SK50 SK60 SK75 SK100 SK120 SK200-1-2-3-4-5-6 SK210 SK220 SK230 SK235 SK250 SK260 SK280 SK300 SK330 SK330-6 SK350 SK400 SK450 SK480 RK200 ect.

|

|

5

|

SH55 SH60 SH75 SH50 SH100 SH120 SH125 SH135 SH140 SH145 SH200 SH200-3-5 SH220-2-3 SH240 SH225 SH260 SH265 SH280 SH300 SH340 SH350 SH400 SH430 SH450 SH40T ect.

|

|

6

|

R55 R60 R80 R130LC-3-5 R150 R190 R200 R200-5 R210 R215-7/9 R220 R225LC-7/9 R245 R260 R265 R280 R290 R290LC-7 R300LC R305LC R320 R335 R330LC R340 R370 R375 R360LC-7 R390 R450LC R470 R485 R500 R450 ect.

|

|

7

|

DH35 DH55 DH60 DH55 DH60 DH80 DH80-7 DH80GOLD DH150 DH200 DH220-3-5 DH225 DH280-5 DH300 DH258 DH370 DH340 DX60-DX200-DX225 DX260 DH290 DH360 DH420 DH500 ect.

|

|

8

|

EC55 EC60 EC140BP EW145BP EW160BB EC210 EC240 EC290 EC360LC EC380 EC460 EC480 EC700 ect.

|

|

9

|

SY55 SY60 SY65 SY70 SY75 SY85 SY95 SY115 SY135 SY155 SY195 SY200 SY205 SY215 SY220 SY225 SY235 SY245 SY285 SY300 SY305 SY310 SY335 SY365 SY375 SY395 SY415 SY420 SY485 ect.

|

|

10

|

HD100 HD250 HD450 HD512 HD513 HD516 HD550 HD700 HD770 HD800 HD820 HD880 HD900 HD1023 HD1430 HD2045 ect.

|

|

11

|

CLG904 CLG905 CLG906 CLG907 CLG908 CLG915 CLG150 CLG920 CLG921 CLG922 CLG924 CLG925 CLG933 CLG936 CLG939 CLG942 CLG948 CLG950 CLG952 CLG200 CLG205 CLG220 CLG225 ect.

|

|

12

|

XE55 XE60 XE65 XE75 XE80 XE85 XE135 XE150 XE155 XE200 XE205 XE215 XE225 XE245 XE270 XE305 XE335 XE370 XE380 XE400 XE470 XE490

XE700 ect.

|

|

13

|

YC13 YC15 YC20 YC18 YC18-3 YC35 YC45 YC55 YC65 YC65-2 YC85 YC85-3 YC135 YC210 YC225LC YC230 YC350 YC400ect.

|

|

14

|

U15 KX41 KX41-2 KX135 KX185 KX155 KX161 KX163 KX165 KX183 ect.

|

|

15

|

8045 8055 8056 8060 8061 8065 JS130 JS140 JS200 IS210 JS220 ect.

|

|

16

|

R914 R924 R944 R944CLC ect.

|

|

17

|

ViO35 ViO55 ViO75 ect.

|

|

18

|

CX50B CX55 CX210 CX210B CX460 ect.

|

|

19

|

JCB220 JCB8056 JCB8045 JCB8055 JCB8060 JCB8061 JS130 JS200 JS210 JS220

|

|

20

|

XG60 XG808 XG815 XG820 XG822 XG823 XE60 XE210 XE215 XE150 XE230 XE370

|

Four-point contact ball slewing bearing

Double-row ball slewing bearing

Three-row cylindrical roller slewing bearing

Cross roller bearing

Raceways

The raceways of slewing rings are quenched on the surface. Its quenching hardness is HRC55-62, making sure that its effective hardening depth is enough.

Production Process

Raw material

LYJW bearing rings are made of high quality 42CrMo/50Mn and the raceway surface is quenched. We can provide rings of other materials according to customer’s specific requirements.

Rough turning

* After rough turning, the workpiece is detected by an ultrasonic flaw detector to examine cracks or other flaws and ensure the bearing’s stable quality and normal service life.

Heat treatment

* Perform medium frequency hardening on the surface of bearing raceway to form a hardened layer with hardness≥55HRC, depth≥4mm and the width of soft zone is≤50mm with a “S” mark on it.

Gear Processing

For bearings with external or internal gear, gear processing should be performed prior to grinding process to achieve the required

gear accuracy.

gear accuracy.

Drilling

Program on the CNC drilling machine according to the drawing and verify the size accuracy prior to drilling holes.

Grinding

Fine grinding: 46 or 60 grit resin grinding wheel is used to finely process the slewing bearings and achieve the required surface finish and size accuracy.

Assembly

After grinding, pre-assembly is carried out to calculate and adjust the clearance.After adjusting the clearance, check the start friction torque. If it is not acceptable, adjusting the race way and clearance again to achieve the required value.

Inspection- Calipers

LYJW performs strict quality control in compliance with ISO9001-2015 Quality Management System. Every process from materials to finished products is inspected and documented to control the quality of every piece of bearing.

Dial indicator

LYJW performs strict quality control in compliance with ISO9001-2015 Quality Management System. Every process from materials to finished products is inspected and documented to control the quality of every piece of bearing.

Altimeter

LYJW performs strict quality control in compliance with ISO9001-2015 Quality Management System.

Quenching hardened layer depth tester

LYJW performs strict quality control in compliance with ISO9001-2015 Quality Management System.

Packaging & Shipping

The qualified products are cleaned, greased, packaged, crated, and shipped to the customer with related certifications.