NaN / 0

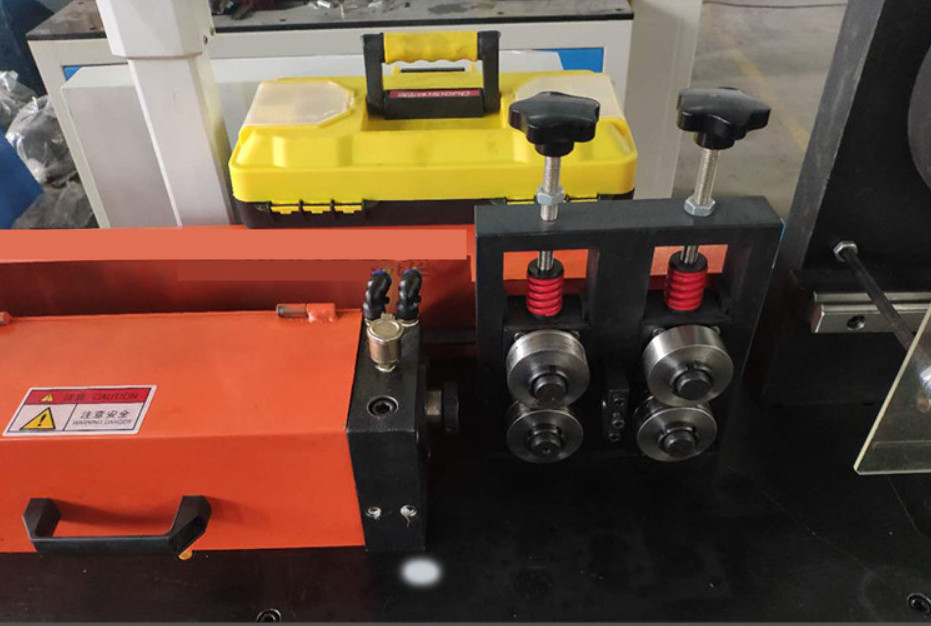

CNC steel metal wire straightening and cutting machine wire straightening steel wire straightening and cutting machine

Get Latest Price

US$ 6260

≥1 Pieces

Quick Details

Place of Origin:

Shanghai, China

Brand Name:

Qipang wire straightening and cutting

Weight (KG):

800

Marketing Type:

wire straightening and cutting

Product Details

Product Description

CNC steel metal wire straightening and cutting machine wire straightening steel wire straightening and cutting machine

Specifications

Configuration parameters of straightening and cutting automatic metal iron wire :

1 two servo motors, 1.5 kw traction and 1:10 planetary reducer, cut off 1.5 kw,

2 cut off the PLC touch screen electronic CAM system,

3 servo motor brand, servo motor straightening and cutting machine,

4 fuselage length 1850mm wide 780mm total height 1300mm.It weighs about 498 kilograms,

5 the total weight of the automatic spreader is 90kg,

6. The control mode includes inverter analog control system,

7. Minimum diameter: 250mm; maximum diameter: 500mm,

8 the weight of the spreader is about 90kg.

Configuration parameters of straightening and cutting automatic metal iron wire :

1 two servo motors, 1.5 kw traction and 1:10 planetary reducer, cut off 1.5 kw,

2 cut off the PLC touch screen electronic CAM system,

3 servo motor brand, servo motor straightening and cutting machine,

4 fuselage length 1850mm wide 780mm total height 1300mm.It weighs about 498 kilograms,

5 the total weight of the automatic spreader is 90kg,

6. The control mode includes inverter analog control system,

7. Minimum diameter: 250mm; maximum diameter: 500mm,

8 the weight of the spreader is about 90kg.

|

Type and wire diameter: |

QP-φ0.2-1mm

|

QP-φ1-6mm

|

QP-φ7-12mm

|

||

|

Cutting range: |

10mm – 99999mm straightening and cutting automatic metal iron wire

|

|

|

||

|

Max cutting speed: |

200pcs/min

400 pcs/min |

|

|

||

|

Wire feeding speed: |

20-60m/min

|

20-80m/min

|

20-60m/min

|

||

|

Length error: |

±0.2mm straightening and cutting automatic metal iron wire

±0.2mm for uniform speed |

|

|

||

|

Wire material: |

Common carbon steel wire and stainless steel wire |

|

|

||

|

Accessories: |

Withdrawable wire rack, Movable receiving pocket, Recommended automatic wire rack for lines above 3.0 |

|

|

||

|

Feeding stand: |

1000*300*150 straightening and cutting automatic metal iron wire

|

|

|

||

|

Feeding motor: |

2.0kw servo motor straightening and cutting automatic metal iron wire |

|

|

||

|

Straightening motor |

Custom adjustable speed motor 3KW/2880r |

|

|

||

|

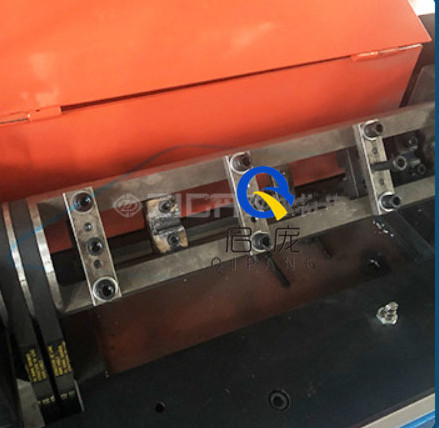

Cutting shear motor: |

2.8KW Cut off servo motor straightening and cutting automatic metal iron wire |

|

|

||

|

Rail module: |

Nextron straightening and cutting automatic metal iron wire |

|

|

||

|

Number of feeding rollers: |

2 group (4 pairs rollers) straightening and cutting automatic metal iron wire |

|

|

||

|

HMI: |

7 inch touch screen straightening and cutting automatic metal iron wire |

|

|

||

|

Number of straightening rollers: |

8 pcs straightening and cutting automatic metal iron wire |

|

|

||

|

Material of shear: |

Cr12 Steel, partly made by Nextron straightening and cutting automatic metal iron wire |

|

|

||

|

Electric box brand:

|

Relay—IDEC,

contactor--CHINT switching power supply—DELTA, Motion Controller—Guangzhou shifu |

|

|

||

|

Measurement(length*width*height)

|

1700*700*1350(mm) straightening and cutting automatic metal iron wire

|

|

|

||

Specification

Package

Other product

CNC steel metal wire straightening and cutting machine cutting machine wire straightening wire straightening and cutting

For more details, please contact:

WhatsApp: +86 15001830288 Wechat: 18136540512 Email:

shanghaixj123@yeah.net

Hot Searches