NaN / 0

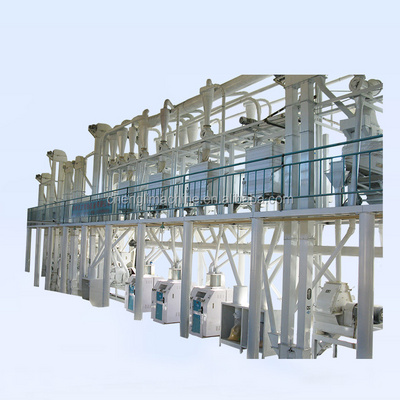

10-100 TPD wheat flour milling machine /High efficient wheat flour mill plant/ Wheat grinding machine

Get Latest Price

US$ 56000

≥1 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

HNLY

Production Capacity:

According to Customers' Need

Voltage:

220V/380V

Product Details

10-100 TPD wheat flour milling machine /High efficient wheat flour mill plant/ Wheat grinding machine

product Description

Product description

This set of machines has high efficiency and low energy consumption, which is designed by our professional engineers. The machine has high output rate with good quality flour.

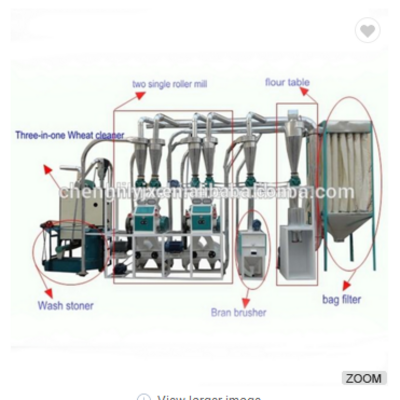

Complete set of wheat or maize flour machine can be divided into THREE parts:

1. cleaning part

2. milling part

3. packing part

1. Cleaning part

to clean out the middle and small impurity from wheat. e.g., dust, stone, magnetic material, wheat was bitten by insect and so on. Includes beating, screening, destoner, magnetic separator and dampening. This section is to prepare for milling part and to protect the machinery as well.

2. Milling part

The second step, to mill the grain and separate the flour, bran and other by-product:

(1) Mill: mill the grain to break the integrity by the roller moving.

(2) Sifter: to separate the flour,bran and other by-product, also separate large size and small size to ensure flour quality.

3. Packing part

The third step, the packing machine can be manual or automatic weighting and packing.

4. PLC controlling system

To controlling the whole set of machinery to work well and showing the process of working.

Features of wheat flour mill machine

1. Roller mills are manufactured precisely and controlled by manual or pneumatic mode. It can make better grinding effect comparing with other ordinary mills.

2. Complete sets of large wheat flour mill machine adopt various configuration modes for different choices. There are streamlined design, reasonable layout, beautiful performance .

3. It can be installed on a steel frame structure or in a concrete building.

4. The large wheat flour mill machine is with advanced technical process and flexible adjustment.

5. Good after-sales service and spare parts is supplied for complete set of large wheat flour mill machine.

Note

- The detailed cleaning and milling flow sheets could be designed following customers’ special requirement and the plant location.

- The wheat silos and flour and bran warehouse are excluded in the above.

- For more information or other model, please contact us.

Packaging & Shipping

Packaging

Packaging: all machines covered by plastic film firstly and then packed in wooden case to best protect the machine during long time transportation.

shipping

Shipping: All machines will be sent by sea, if you need other kind of transportation, please inform us in advance. And all machines would be shipped in 7 days after the receipt of payment. Before and after shipping, we will take photos of machines and send photos to client.

Our Services

Our service

1. One year quality warranty for the machine and spare parts

2 . Overseas engineers service for installation

3 . Whole-life after-sales service and free consultation

4 . Customized requirements available

5 . Technician guide at the site.

6 . 24Hr online service

FAQ

1.Q :Are you the factory?

A:Yes, We are a professional manufacturer for several years.

2.Q: Where is your factory located?

A:Our factory is located in Jiaozuo, Henan Province.

3. Q:How about the INSTALLATION?

A:Engineers available to service machinery overseas,including installation,commission and training,etc.

4. Q:Can your company accept the customized product?

A:Yes,OEM &ODM service is available.We can make the products according to your size,design,color, It will be better if you can send us the product pictures for our reference.

5.

Q: How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

Any questions, please don't hesitate to contact us!

Buyer Feedback

Our Factory aid Zambia 240TPD Maize Flour Mill Plant

Customer visit

Hot Searches