NaN / 0

cookies making machine small automatic cookie filler machine fortune cookies making machine

Get Latest Price

US$ 16800

≥1 Sets

Quick Details

Marketing Type:

Hot Product

Place of Origin:

Guangdong, China

Brand Name:

skywin

Voltage:

220V/380V

Product Details

Product Description

400 MM Tray Type PLC Control Cookie Making Machine

Small mini Cookie machine can produce wire cut cookie ,deposit cookie ,double color cookie, different shape just need to change the mold ,we also can design depend on your requirement.

Main Features:

1. Conveyor drive roller: Nylon rubber material

2. Siemens Brand PLC Touch-screen control

3. Conveyor PU belt: non-toxic oil-resistant material

4. Conveyor plate Material:304 stainless steel

5. Two sets mold are free, one set for wire cutting and one set for deposit

6. PU conveyor belt thickness:1.4 mm

7. High transmission efficiency ,low noise ,work stable

8. Servo motor is by Chinese famous brand ,low noise,high efficiency ,long service life

9. Capacity : 50-150 kg/h

10. Machine working width :400 mm ,tray size:600*400 mm

11. Voltage: as per customer country

Depositing Cookies Sample:

Wire Cut Cookies Sample:

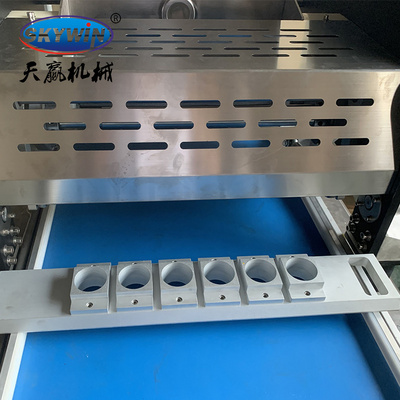

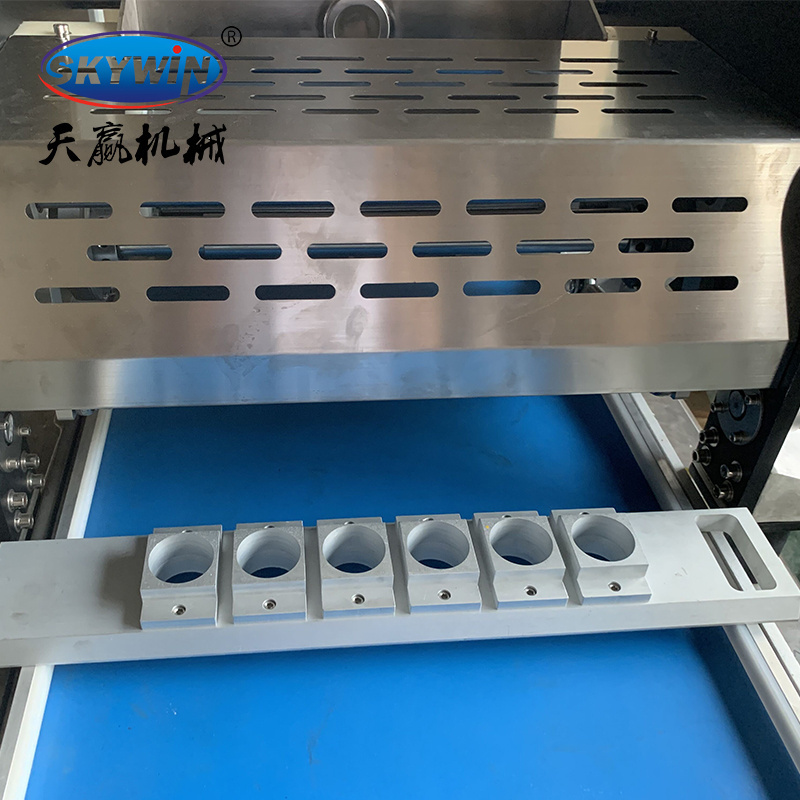

Cookies Mold:

* The video and pictures are for reference only

Specification

|

Tray Type Cookies Machine

|

|

|

|

Capacity

|

About 50kgs/hour~150kgs/hour

|

|

|

Produce speed

|

0-45 times/min

|

|

|

Dimension

|

1450*1350*1050 mm

|

|

|

Weight

|

390KG

|

|

|

Material

|

Covered by 304 Stainless steel

|

|

|

Touch Screen Control

|

Siemens brand

|

|

|

Serve Motor Control

|

Delta brand

|

|

|

Electrical Control Components

|

Delta brand

|

|

|

Warranty

|

1 year

|

|

Related Product

Packing & Delivery

Step 1: Mechanical surface coated with preservative solution (to protect stainless steel).

Step 2: The plastic cushion packing machine (prevent bump).

Step 3: Plastic film packaging (to prevent ventilation).

Step 4: Wooden case / frame packaging (easy to transport).

Step 5: Tie the bandage outside of the wooden case (reinforcement overall).

Step 2: The plastic cushion packing machine (prevent bump).

Step 3: Plastic film packaging (to prevent ventilation).

Step 4: Wooden case / frame packaging (easy to transport).

Step 5: Tie the bandage outside of the wooden case (reinforcement overall).

Hot Searches