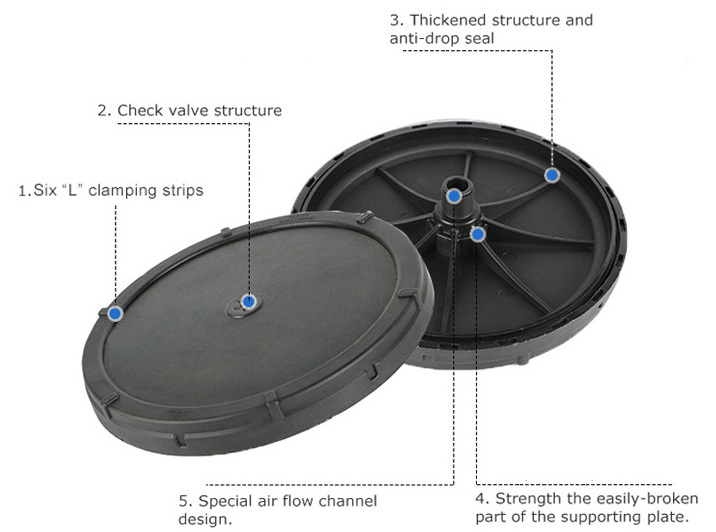

2.Check valve structure. When operation stops, the membrane covers the structure under the action of rebound force and water depth pressure to prevent the backflow of mud water.

3.Mechanical assembly production line, hot welding instead of adhesive process, to ensure adequate supply, uniform productquality, stable and reliable.

4.The spanner position is designed. Spanner is used to replace the traditional hand-twist installation, avoid membrane damage. And installation is convenient and reliable.

5.Product adopts single-ear pole clamp which make product bear 360 degree uniform stress. Under heat expansion and contraction as well as vibration, it can play a spring regulating effect. All single-ear clamps are 316 stainless steel material. It is more reliable in sewage.

6.Six channel design, increase ventilation cross - sectional area, reduce resistance, efficient and energy - saving. The multiple positions of the membrane jointly bear air friction, reduce local wear and extend aerator membrane service life. Also, promote product 360 ° aeration, improve the product efficiency.