NaN / 0

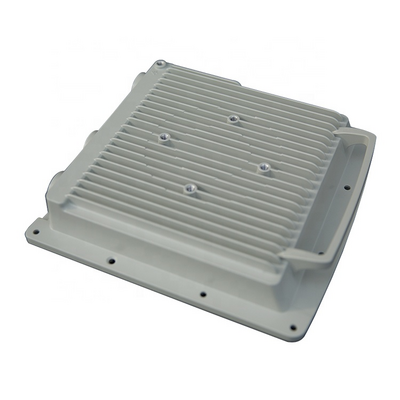

Custom Die Casting Custom Metal Aluminum Zinc Die Casting Services

Get Latest Price

US$ 11

≥1 Pieces

US$ 2

≥1000 Pieces

Quick Details

Place of Origin:

Guangdong, China

Brand Name:

customized

Model Number:

customized

Material:

Zinc Alloy

Product Details

|

Processing Technic

|

Die casting

|

|

|

|

|

|

Post treatment

|

Oil painting, powder coating, anodized, pickling, mirror polishing, etc

|

|

|

|

|

|

Part material

|

ADC12, A380, magnesium alloy, zinc alloy or other aluminum alloy all acceptable

|

|

|

|

|

|

Precision machining

|

Die-casting machine(180T----2000T), CNC, milling machine, drilling machine, numerical lathe, Shot blasting machine, Melting,Sawing machine, The air compressor and so on.

|

|

|

|

|

|

Application

|

Auto parts, machinery parts, household parts, Cooker parts, furniture parts, etc

|

|

|

|

|

|

Applied software

|

CROE/PROE, Auto CAD, Slid Work, CAXA, UG, CAD/CAM/CAE

|

|

|

|

|

|

Advantage

|

Advanced equipment and excellent R&D Team, Highly skilled manufacturing process, Strict quality Control System.

|

|

|

|

|

|

Specialized in

|

Processing precision parts according to customer’s 2D/3D drawings.

|

|

|

|

|

|

Packing

|

Usually carton packaging, or PVC bag with a label. Specifically per customer needs.

|

|

|

|

|

|

Service

|

High Quality & Competitive Price & prompt delivery. 24-hour service with prompt reply

|

|

|

|

|

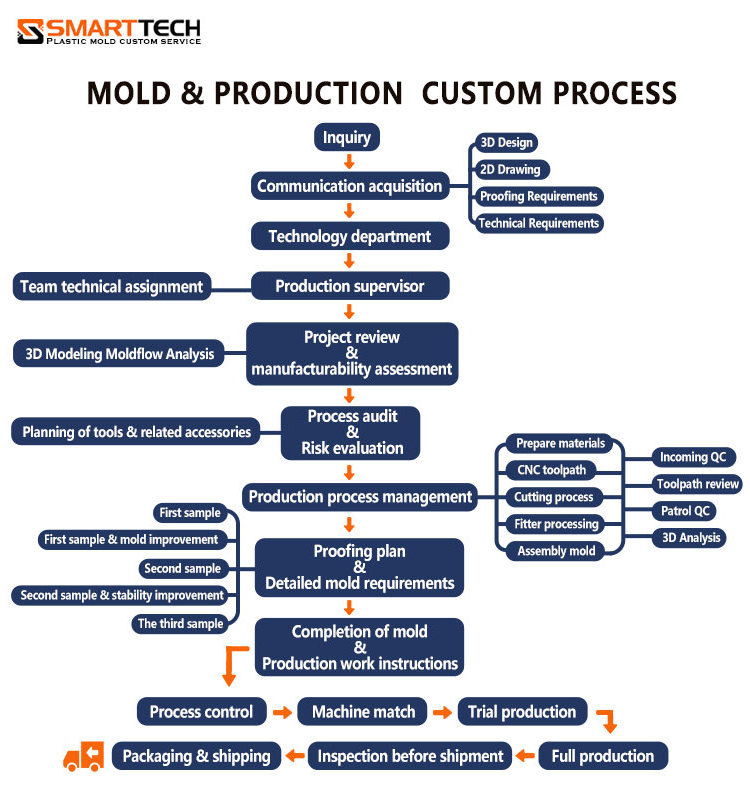

Production Information