NaN / 0

Sheller Processing Plant Commercial Automatic Pecan Nuts Shelling Cracker Walnut Crusher Machine

Get Latest Price

US$ 20000

≥1 Sets

US$ 17000

≥3 Sets

US$ 15000

≥5 Sets

Quick Details

Type:

Walnut Processing Machine

Use:

Walnut Shelling Cracking

Production Capacity:

500kg/h

Place of Origin:

Henan, China

Product Details

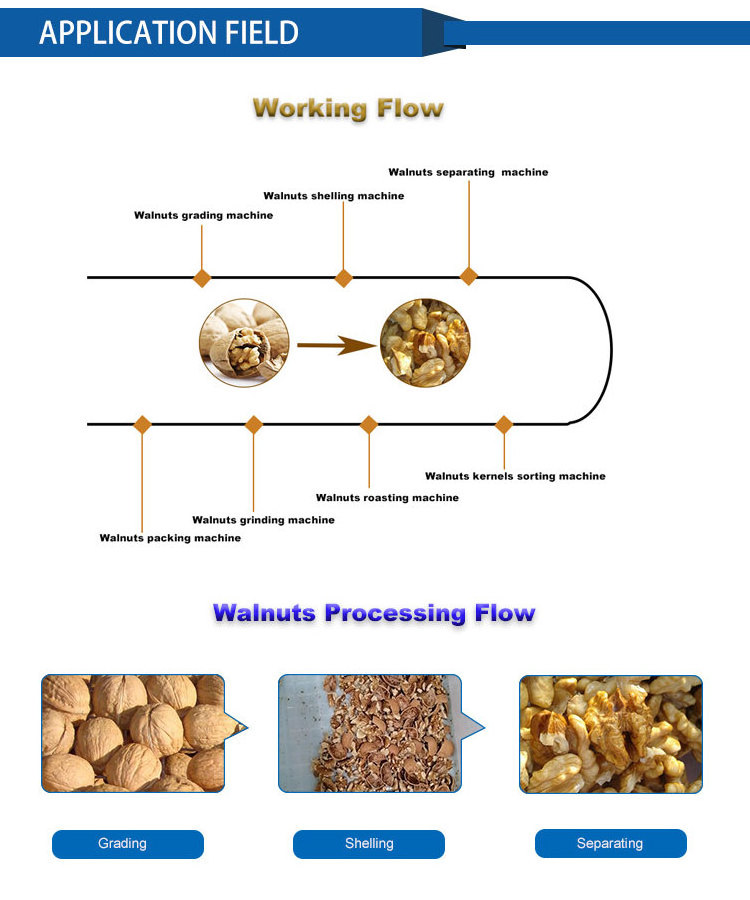

Walnut shelling machine is composed of frame, rotor, motor, fan, screen, feeding hopper, triangle belt wheel and its transmission triangle belt. After the normal operation of the machine, the walnuts will be put into the feeding hopper evenly and continuously,and the walnuts will be broken under the repeated striking, friction and collision of the rotor, and the kernels and the broken shells will be crushed in the rotating rotor. Crushed shells in the rotor's rotating wind pressure and under the blow, through a certain aperture of the screen from the large-hole screen, after screening the small skinned fruit to replace the small-hole screen for the Second shelling filtering, separation. Walnut shells, grains in the rotating fan under the action of the blowing force, so that the light weight of the shells blown out of the body, the heavier weight of the fruit through the vibration of the The heavier fruit will be screened by vibrating sieve to achieve the purpose of clearing。

1) This Automatic walnut Kernel Dehusker Walnut Cracker Shelling Machine is mainly used for the different sizes of walnut, different nuts, beans and so on.The whole process of walnut shelling can be lifted by conveyor belt. Realizing automatic production.

2) Screen is divided into three levels or medium level, more easy to store sales.

3) By one, two, tertiary of vibrating screen, a screening classification at the same time, the live screen surface mesh type 6 -- 10 mm, according to different varieties, replacing sieve to separate the size of the qualified level.

4) Design reasonable low broken rate, nuclear class is by far the most ideal processing equipment.

This machine is mainly used for breaking nuclear hard shell. The level of processing hulling roller, vibration sieve,a stripping level specifications of the walnuts, and other hard shell,adjusting the processing roller gap after the removal of other specification,and so on. Rational design of the low rate of broken makes it currently the most ideal nuclear processing equipment.

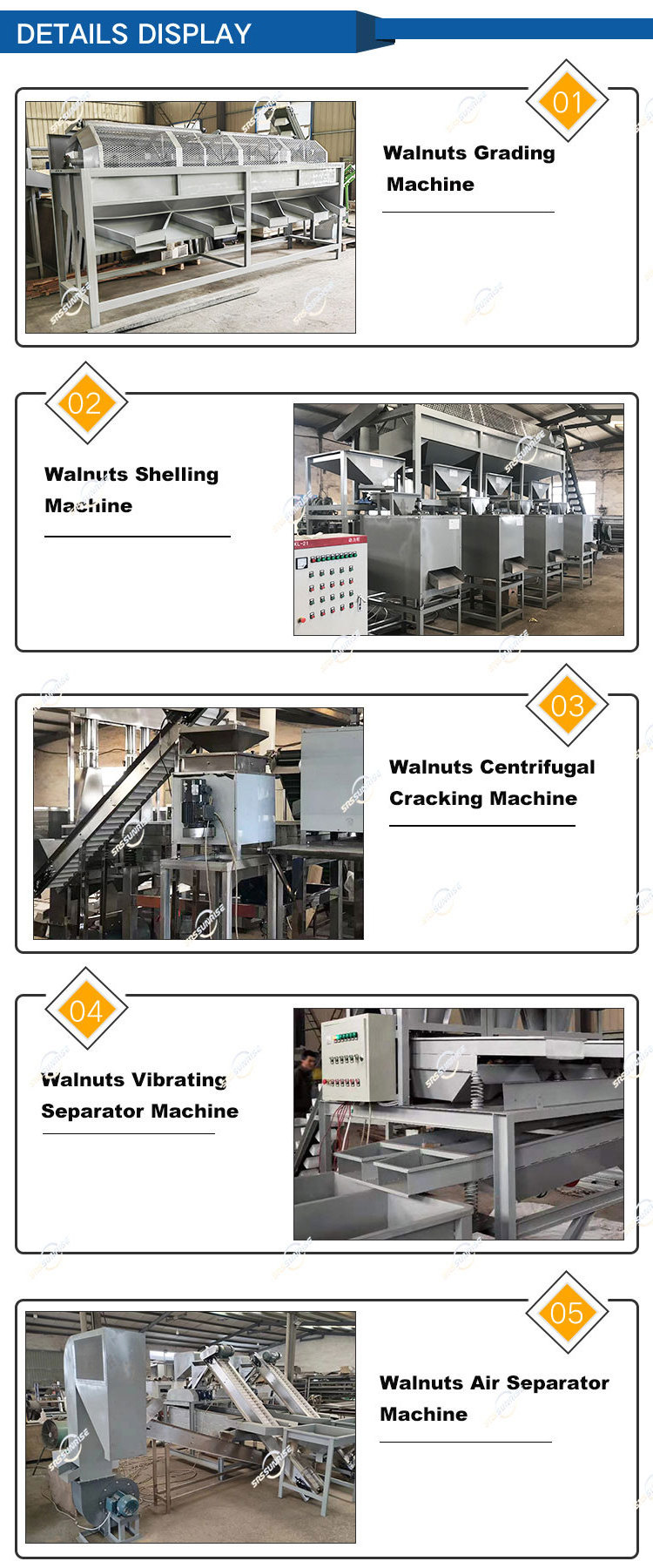

1. This walnut shelling machine is mainly used for walnut hard shell.

2. Capacity and nuts integrity rate will be different for different varieties of walnuts.

3. This machine feeds from upper part and finish the shelling inside.

4. There are two control measures during shelling. The first is adjusting the motor speed to comply with the internal wind. The second is adjusting the internal space.

Product Details

|

Item

|

Walnuts Shelling Machine

|

|

Capacity

|

200-400kg/h

|

|

Voltage

|

380v

|

|

Integrity rate

|

70%

|

|

Dimensions

|

1.15*0.75*1.2m

|

|

G.W.

|

160kg

|

|

Item

|

Walnuts vibrating separator machine

|

|

Power

|

0.5kw

|

|

Voltage

|

380v

|

|

Frequency

|

50hz(Adjustable)

|

|

Dimensions

|

2.4*1.4*1.8m

|

|

G.W.

|

600kg

|

|

Item

|

Walnuts centrifugal cracking machine

|

|

Capacity

|

200-400kg/h

|

|

Voltage

|

380v

|

|

Integrity rate

|

70%

|

|

Power

|

1.1kw

|

|

Dimensions

|

1.15*0.75*1.2m

|

|

G.W.

|

160kg

|

Q1: What power do you use in your factory?-V,-Hz, 3 phase or single phase?

(Like 220 V , 50 Hz , single or 380 V, 50 Hz ,3 phase...etc)

Q2: Can I Put my Logo on the machine?

Yes, Sure .

Q3. How can I trust you for the first-time business?

We can supply the business license and certificates. if you still worry about our company,

Q2: Can I Put my Logo on the machine?

Yes, Sure .

Q3. How can I trust you for the first-time business?

We can supply the business license and certificates. if you still worry about our company,

we suggest using Alibaba trade assurance service for all transactions to protect your money

and ensure our service for you.

Q4. How can you ensure the machine's quality after we purchase the order?

Before delivery, we will produce the equipment according to the agreed requirements, and

Q4. How can you ensure the machine's quality after we purchase the order?

Before delivery, we will produce the equipment according to the agreed requirements, and

after production, we will provide detailed operating instructions, testing videos, certification

documents, etc. Alternatively, you can arrange a third-party inspector to do inspection and

give you report.

Q5: How about the after-sale service and guarantee period?

1. 18-month warranty period for whole machine except for human factors etc. and 18 months’

1. 18-month warranty period for whole machine except for human factors etc. and 18 months’

after-sale service starts from the date when you receive machine .

2. Consultation services for whole machine life, and 24 hours technical support by email or video on line.

3.English software, user manual and the installation & debugging by our experienced technicians.

2. Consultation services for whole machine life, and 24 hours technical support by email or video on line.

3.English software, user manual and the installation & debugging by our experienced technicians.

Hot Searches