NaN / 0

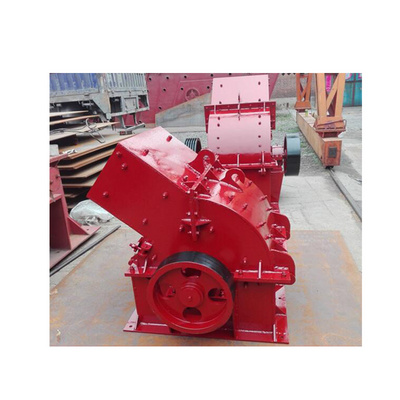

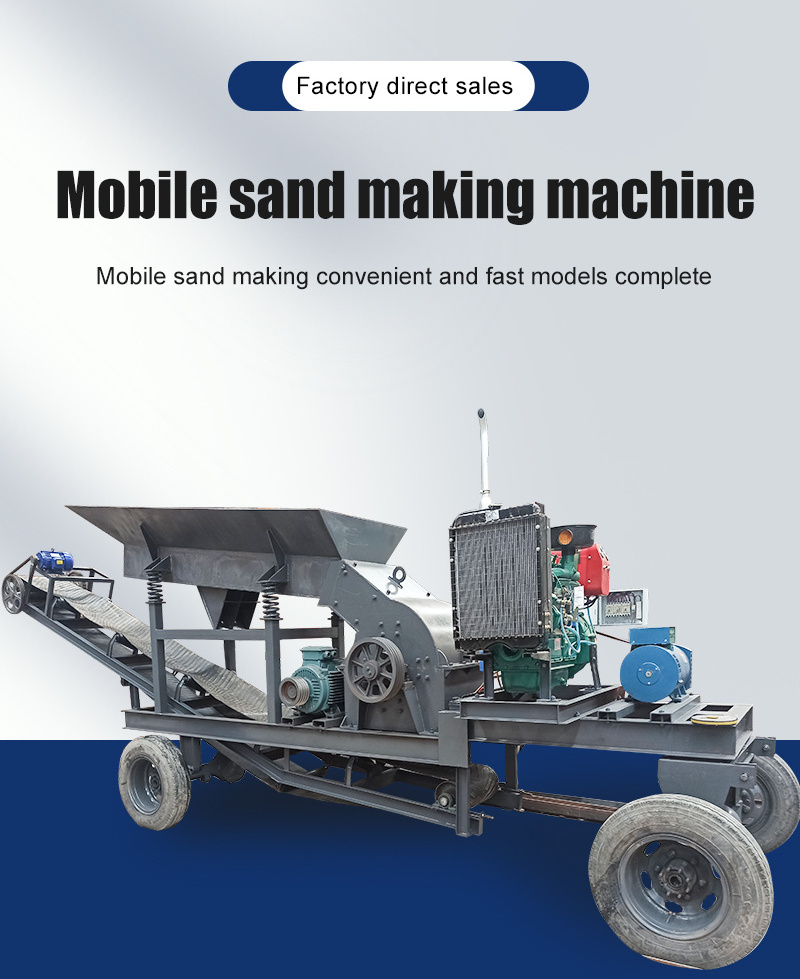

Diesel Powered Rock Crusher Gold Crushing Plant Hammer Breaking Sand Making Machine Mineral Grinding Hammer Mill

Get Latest Price

US$ 630

≥1 Pieces

US$ 620

≥5 Pieces

Quick Details

Marketing Type:

Hot Product 2024, New in 2024

Place of Origin:

Henan, China

Brand Name:

lingzhi

Voltage:

380V

Product Details

Who am I

Hammer sand making machine is a commonly used crushing equipment, mainly used to break large rocks, ores and other materials into the required particle size. It uses a high-speed rotating hammer head to impact the material, so as to achieve the crushing of the material. Hammer sand making machine is widely used in mining, construction, highway, railway and other industries.

The main components of the hammer sand making machine include rotor, hammer head, counter plate, bracket and so on. The rotor is the core component of the hammer sand making machine, which breaks the material through high-speed rotation. The hammer head is a part of the rotor that breaks the material by hitting it at high speed. The counter plate is used to adjust the particle size of the material, and the bracket plays the role of fixing the rotor and the hammer head.

The working principle of the hammer sand making machine: when the rotor rotates at high speed, the hammer head will rotate and impact the material at high speed. After the impact of the hammer, part of the material is broken into small particles, and the other part bounces back. Through the adjustment of the counter plate, the small particle material is broken into the desired particle size.

Advantages of hammer sand making machine:

Wide range of application: The hammer sand making machine is suitable for the crushing of various hardness materials, including limestone, granite, basalt and so on.

Low energy consumption: The hammer sand making machine uses a high-speed rotation method, and the material is faster when it is impacted, so the energy consumption is low.

Low noise: When the hammer sand making machine is running, the noise is small, and the working environment will not have much impact.

Simple maintenance: The hammer sand making machine has simple structure and is easy to maintain and maintain.

Disadvantages of hammer sand making machine:

1,Low yield: Due to the slow speed of the hammer when breaking the material, the yield is relatively low.

2,Wearing parts wear quickly: the service life of wearing parts such as hammer heads and counterattack plates is relatively short and needs to be replaced frequently.

3,High operation requirements: The operation requirements of the hammer sand making machine are high, and it needs to be mastered to ensure normal operation.

Working principle

Hammer sand making machine is a commonly used crushing equipment, mainly used to break large rocks, ores and other materials into the required particle size. It uses a high-speed rotating hammer head to impact the material, so as to achieve the crushing of the material. Hammer sand making machine is widely used in mining, construction, highway, railway and other industries.

The main components of the hammer sand making machine include rotor, hammer head, counter plate, bracket and so on. The rotor is the core component of the hammer sand making machine, which breaks the material through high-speed rotation. The hammer head is a part of the rotor that breaks the material by hitting it at high speed. The counter plate is used to adjust the particle size of the material, and the bracket plays the role of fixing the rotor and the hammer head.

The working principle of the hammer sand making machine: when the rotor rotates at high speed, the hammer head will rotate and impact the material at high speed. After the impact of the hammer, part of the material is broken into small particles, and the other part bounces back. Through the adjustment of the counter plate, the small particle material is broken into the desired particle size.

Specifically, when the rotor starts to operate, the hammer head rotates and hits the material at high speed. After the impact of the hammer, part of the material is broken into small particles, and the other part bounces back. Then, the small particle material is broken into the desired particle size through the adjustment of the counter plate. At the same time, the rotor is constantly rotating, and the material is constantly broken until the required particle size is reached.

In short, the hammer sand making machine impacts the material through the high-speed rotating hammer head to achieve the crushing of the material. It has the advantages of wide application range, low energy consumption, low noise, simple maintenance, etc., but the output is low, the wearing parts wear fast, and the operation requirements are higher.

If you are interested with our products, please don't hesitate to contact us now!

You can tell me the following questions and then I can send you an accurate quote, including additional discounts!

1. Which machine do you need? Such as small mining crusher, mill or separator.

2. What kind of raw materials do you plan to process? Such as limestone, granite or iron ore.

3. The capacity you need. Like 100 tons per hour or 2,000 tons per day.

4. Your contact information. Both an email and a phone number are required so that we can contact you more easily.

Hot Searches