NaN / 0

100 liter cheese making processing machine Jacket Heated Cooking Kettle for making sauces tomato sauce making machine

Get Latest Price

US$ 1400

≥1 Sets

Quick Details

Marketing Type:

Hot Product 2022

Brand Name:

HunDom

Place of Origin:

Guangdong, China

Voltage:

220V-480V

Product Details

Product Description

100 liter cheese making processing machine Jacket Heated Cooking Kettle for making sauces tomato sauce making machine

The stainless steel jacket kettle can be applied to a wide variety of foods processing, such as candy, medicine, dairy, liquor,

cake, candied fruit, drink, canned goods, sauced meat etc.It also can be used in making soup, cooking stir-fry, stewing meat, cooking porridge and so on, and it is a wonderful equipment to improve quality, reduce time and improve working conditions during foods processing.

Optional Type of Jacket Kettle:

Gas Jacket Kettle

you can use natural gas, LGP and any other kind of heating medium that you have.To natural gas, liquefied petroleum gas as a heat source, full combustion, smoke-free dust-free,a small amount of carbon deposition, no environmental pollution.The use of powerful energy- saving burners, fire fierce, thermal efficiency than similar products increased by 25%, air consumption than similar products to reduce about 20%.

Gas Jacket Kettle

you can use natural gas, LGP and any other kind of heating medium that you have.To natural gas, liquefied petroleum gas as a heat source, full combustion, smoke-free dust-free,a small amount of carbon deposition, no environmental pollution.The use of powerful energy- saving burners, fire fierce, thermal efficiency than similar products increased by 25%, air consumption than similar products to reduce about 20%.

Steam Jacket kettle

with Dimple jacket inside the walls for steam inject and heating. It takes the steam as thermal source. The inner surface contacted with the product are all SUS304 Or SUS316.

Electrical Jacket Kettle

Compared with steam heating, the heating temperature of the electrical jacket kettle is higher than steam jacket kettle, Which can shorten the cooking time.

Also could be made according to customers' requirement

Main technical parameter

|

Model

|

|

HD-50

|

HD-100

|

HD-200

|

HD-300

|

HD-400

|

HD-500

|

|||||||

|

Equipment volume

|

|

50

|

100

|

200

|

300

|

400

|

500

|

|||||||

|

Working pressure in jacket

|

|

<0.2

|

|

|

|

|

|

|||||||

|

Evaporating quantity

|

|

30

|

40

|

65

|

75

|

100

|

150

|

|||||||

|

Heating area

|

|

0.4

|

0.45

|

1

|

1.15

|

1.44

|

1.9

|

|||||||

|

Energy consumption

|

|

33

|

44

|

72

|

90

|

110

|

165

|

|||||||

|

Weight of equipment

|

|

170

|

190

|

230

|

320

|

360

|

485

|

|||||||

|

Outline dimension

|

Length

|

720

|

800

|

1400

|

1450

|

1500

|

1600

|

|||||||

|

15000

|

Width

|

600

|

650

|

700

|

800

|

850

|

900

|

|||||||

|

20000

|

Height

|

830

|

950

|

1100

|

1110

|

1140

|

1150

|

|||||||

|

Can according to customer’s requirement customize.

|

|

|

|

|

|

|

|

|||||||

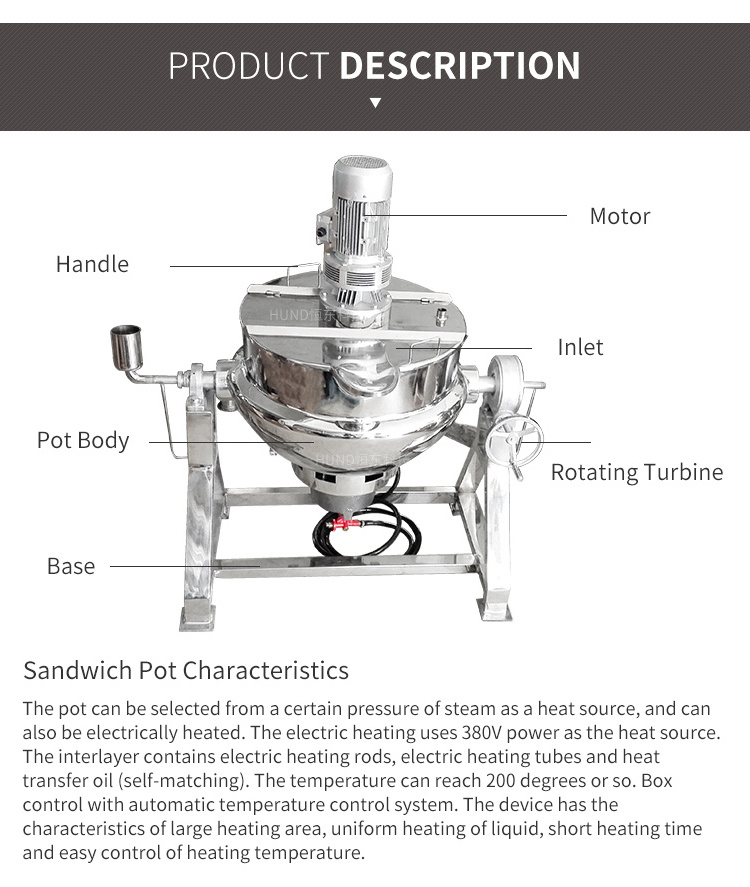

Structure:

Jacketed kettle can use steam with certain pressure as the heat source, or electric heating. The electric heating uses

220V/380V/415V(customized) power as the heat source. The jacket is equipped with electric heating rod, thermocouple and heat transfer oil (self-made), which can reach 200 degrees. It is controlled by an electric control box and has a built-in temperature control system. The equipment has the advantages of large heating area, uniform heating, short boiling time and easy control of heating temperature.

Mirror polishing, electric control box and bracket are made of stainless steel SS304; the brand of electrical components is Chint or Schneider.

Capacity, jacket working pressure, motor power, heating power and mixer structure can be customized.

Wall scraper:: using whole piece of Teflon material, easy to clean and replace, less dead angle, reduce material sticking to the wall.

Semicircle design of discharge outlet: it is convenient to put materials upside down without dead angle.

Rotating device: the cast iron integral worm gear is adopted, which meets the safety standard (SUS 304 hygienic food grade).

Oil filling inlet: 102 pipe diameter, convenient and not easy to flow out.

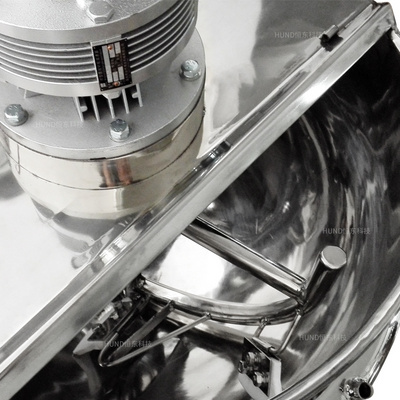

Mixing device:

1. The reducer is made of Taiwan brand;

2. Detachable frame;

3. Stainless steel bearing;

4. High temperature resistant sealing ring (preventing steam from entering the bearing and reducer);

5. No positioning at the bottom of shaft (reducing residue).

Electric control box:

1. Temperature controller to control temperature

2. Split PT100 thermocouple

3. Schneider electrical components

4. Stainless steel 304 box.

Stainless steel small oil cup : heat transfer oil inlet, when the jacket kettle tilts and rotates, the oil in the oil cup will not

leak out.

Electric heating rod: it is easy to disassemble with threaded connection, and the gasket is made of Teflon material, which can withstand 300 degrees without leakage.

Tilting support: stainless steel 304 material is used as a whole.

Jacketed kettle can use steam with certain pressure as the heat source, or electric heating. The electric heating uses

220V/380V/415V(customized) power as the heat source. The jacket is equipped with electric heating rod, thermocouple and heat transfer oil (self-made), which can reach 200 degrees. It is controlled by an electric control box and has a built-in temperature control system. The equipment has the advantages of large heating area, uniform heating, short boiling time and easy control of heating temperature.

Mirror polishing, electric control box and bracket are made of stainless steel SS304; the brand of electrical components is Chint or Schneider.

Capacity, jacket working pressure, motor power, heating power and mixer structure can be customized.

Wall scraper:: using whole piece of Teflon material, easy to clean and replace, less dead angle, reduce material sticking to the wall.

Semicircle design of discharge outlet: it is convenient to put materials upside down without dead angle.

Rotating device: the cast iron integral worm gear is adopted, which meets the safety standard (SUS 304 hygienic food grade).

Oil filling inlet: 102 pipe diameter, convenient and not easy to flow out.

Mixing device:

1. The reducer is made of Taiwan brand;

2. Detachable frame;

3. Stainless steel bearing;

4. High temperature resistant sealing ring (preventing steam from entering the bearing and reducer);

5. No positioning at the bottom of shaft (reducing residue).

Electric control box:

1. Temperature controller to control temperature

2. Split PT100 thermocouple

3. Schneider electrical components

4. Stainless steel 304 box.

Stainless steel small oil cup : heat transfer oil inlet, when the jacket kettle tilts and rotates, the oil in the oil cup will not

leak out.

Electric heating rod: it is easy to disassemble with threaded connection, and the gasket is made of Teflon material, which can withstand 300 degrees without leakage.

Tilting support: stainless steel 304 material is used as a whole.

Company Introduction

Guangzhou HUNDOM Machinery Equipment Technology Co., Ltd is a high-tech enterprise integrating R&D, manufacture and sales, with more than 18 years of mechanical manufacturing experience. Main production: Stainless steel mixing tank, in-line high shear mixer, transfer pumps, colloid mill etc. HUNDOM has mature technology, professional engineer team and high quality products to meet various requirements in the field of food, pharmaceutical and household chemical industries. We provide a full range of effective solutions and after-sales service for customers, machines are hot sell all over the world. The mature technology and rigorous attitude are the guarantee of HUNDOM Technology’s product quality.

FAQ

Q1 Are you trade or manufacturer?

A: We are a factory with import and export rights, specializing in supporting for global distributors and end users. Also are able to customize your machines according to your requirment.

Q2 How can i trust you when starting our first deal?

A: We can provide the company certification and deal through Alibaba Assurance order, it can guarantee your capital security .

Q3 How to choose the shipment way?

A: By sea, by air and by land are optional, it is according to the order quantity, delivery time, costs and customs policy etc. (Or decide by customers)

Q4 How about the after-sales service?

A: We are able to discuss technical details and offer suggestions online first and over the phone in English.You can get the answers in minutes, instead of days.

Hot Searches