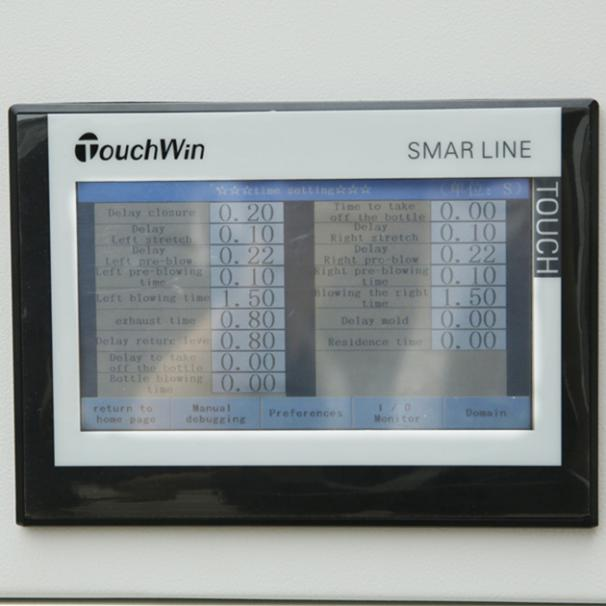

The Programmable Logic Controller (PLC) with a touchscreen display provides all key parameters on a single page for easy operation.

|

Model

|

SC-100 Semi Automatic PET Bottle Blowing Machine

|

|

|

|

Theoretical output

|

100--350 pcs/h

|

|

|

|

Finished bottle

|

Max. bottle volume

|

10L-20L

|

|

|

|

Neck diameter

|

38-160mm

|

|

|

|

Max. bottle diameter

|

270mm

|

|

|

|

Max. bottle height

|

520mm

|

|

|

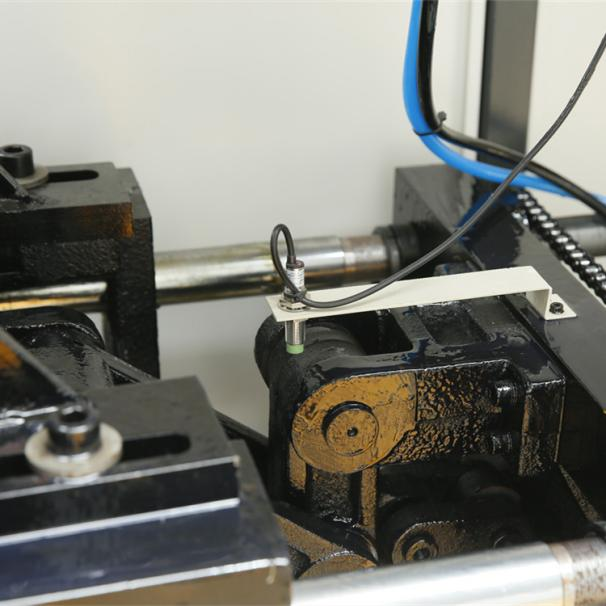

Mold specifications

|

Cavity

|

1 cavity

|

|

|

|

Mold thickness

|

200mm-360mm

|

|

|

|

Open stroke

|

350mm

|

|

|

Electrical system

|

Power voltage

|

380v/3Phase/50HZ

|

|

|

|

Installation power

|

36kw

|

|

|

|

Actual power consumption

|

11kw

|

|

|

Air source

|

Recommend air compressor

|

1.6m³/min 30Kg

|

|

|

Cooling water

|

Recommend water chiller

|

5HP

|

|

|

Blowing machine size

|

Length*width*height/weight

|

2190*740*1900mm/950kg

|

|

|

Auto Loader size

|

Length*width*height/weight

|

2800*670*1600mm/550kg

|

|

|

Components

|

Brand

|

|

PLC

|

Xinje

|

|

Touch Screen

|

Xinje

|

|

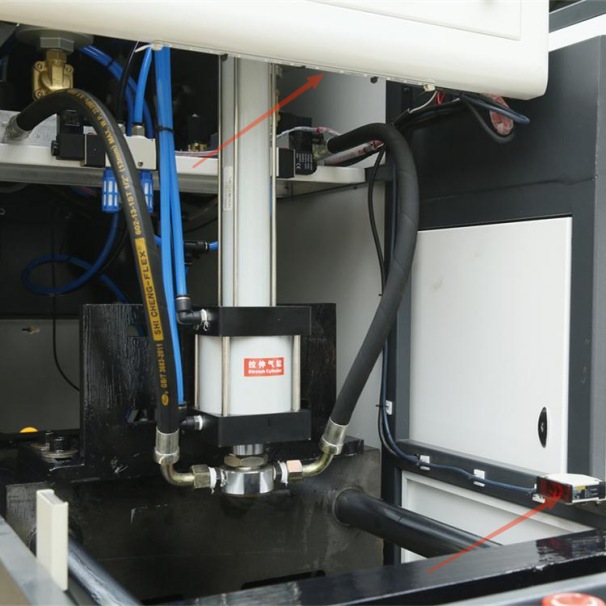

Cylinder

|

Yongcheng

|

|

Blowing Valve

|

Sinopc

|

|

Action valve

|

Festo

|

|

Circuit Breaker

|

Schneider

|