NaN / 0

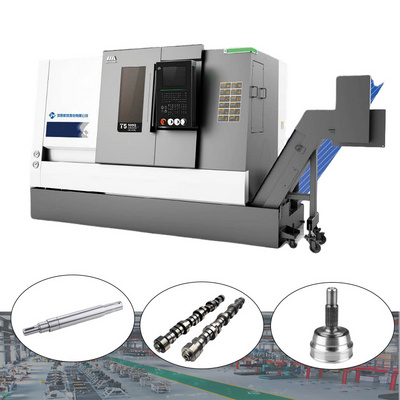

CNC Lathe Machine Training Equipment Mini CNC Lathe Machine 4 Axis Spindle CNC Lathe

Get Latest Price

US$ 10999

≥1 Sets

Quick Details

Type:

Horizontal

Max. Length of Workpiece (mm):

300

Max. Spindle Speed (r.p.m):

4000 r.p.m

Spindle Bore(mm):

46

Product Details

|

Product Description

The SL-X is a CNC turning and milling machine that provides various possibilities of tooling combinations with a more powerful spindle (7.4 HP). It is the best solution to satisfy the diverse demand for metalworking and the goal to minimize the tool change time.

Features

Standard Configuration

Optional Accessories

Applications

Competent in handling the turning process with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with bars diameter up to φ45 mm or single workpieces up to φ350mm.

Demo Services

After-sales Services

FAQ

1: How can I choose machines?

A: for the model selection, please send us the drawing of the turning part, and our engineer will evaluate it and provide the suitable configuration of the CNC lathe fit for your needs. 2: What are the main products of your company? A: SmartLathe concentrated all its resources to develop successfully the SL series of CNC slant bed lathes including the SL-07, SL-25, SL-36, SL-46, and the CNC Turning-Milling machines to help our customers in the field of prototyping, entry-level business, and the craftsman with a bootstrap budget. 3: Where is our factory located? How can I visit there? A: Our factory is located in Foshan City, Guangdong Province, 528300 China. You are warmly welcome to visit our factory. 4: What are the Trade & Payment Terms? A: FOB, CFR, and CIF are all acceptable. T/T,30% initial payment when order,70% balance payment before shipment; Irrevocable LC at sight. 5: What's the MOQ? A: 1 set. We will offer you a better price if you order more. 6. What is the delivery time? A: The full series of standard models are in stock. For a customized one, it depends. 7. Do you have any certificates? A: Yes, our machine is CE-compliant, and our factory is ISO 9001 accredited. 8. What is the warranty period? A: The warranty period is generally 13 months after the B/L date. 9. Machine installation. A: SmartLathe could assign the technician to the place for the on-site installation if requested by the purchaser. 10. Technical Support A: The technical response is available within 12 hours while the solution for the troubleshooting is provided within 48 hours. 11. Demo and Testing A: SmartLathe built a training center for the clients and employees to study the operation of the machine. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could demo per your drawing of turning parts. |

Hot Searches