NaN / 0

Drainage Gutter with Stainless Steel Grating Cover Price

Get Latest Price

US$ 39.5

≥50 Square meters

US$ 37.5

≥150 Square meters

US$ 35.5

≥300 Square meters

Quick Details

Warranty:

More than 5 years

After-sale Service:

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement, Other

Project Solution Capability:

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

Application:

Walkway, Floor, Trench Drainage Cover, Platform

Product Details

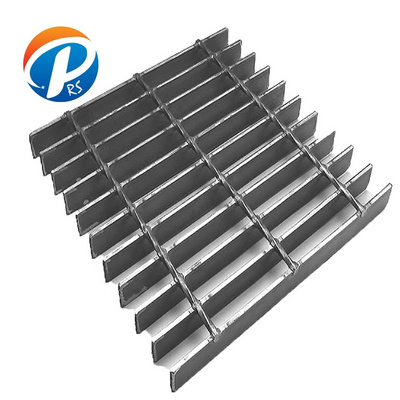

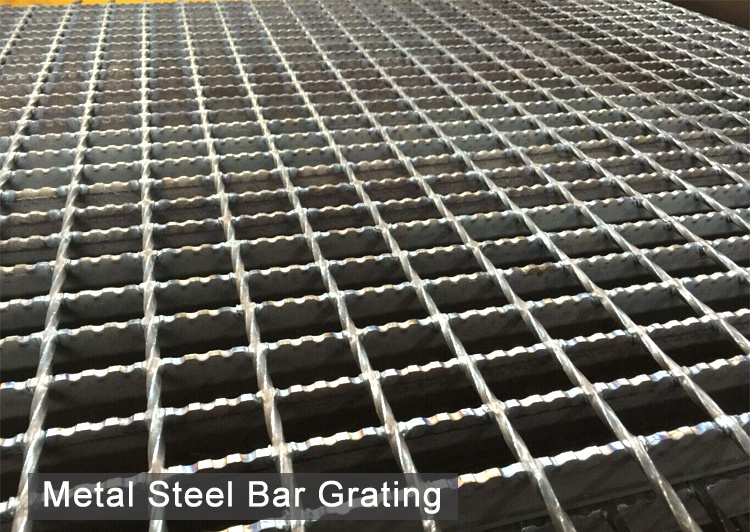

Metal Steel Bar Grating

Product Description

Steel bar grating with high strength and firm structure is made up of carbon steel, aluminum steel, or stainless steel. According to the manufacturing methods, it can be divided into four types: welded, press-locked, swage-locked, and riveted gratings. According to the surface shapes, it can be divided into smooth and serrated gratings. With various styles and sizes for choice, steel gratings are widely used in everyday life, such as stair treads, walkways, platforms, floors, various covers, wheeled equipment, security screens, heavy-duty constructions, and so on.

Learn more about the main components of metal bar grating |

|

| Span: | Total span. |

| Width: | Panel width. |

| Bearing Bars: | Load carrying main element. |

| Bearing Bars Spacing: | Measure from center-to-center of the bearing bars in 1/16″ increments. Standard spacing for industrial flooring is 19/16″(1-3/16″) on center. Other popular spacings are 15/16″, 11/16″, 1/2″, and 7/16″ on center. |

| Bearing Bars Depth: | Ranges from 3/4″ to 7″ depending on anticipated loads. |

| Bearing Bars Thickness: | Ranges from 1/8″ to 1/2″ depending on anticipated loads. |

| Cross Bars: | Used to Secure the position of bearing bars. |

| Cross Bar Spacing: | Measured from center-to-center of cross bars in 1″ increments. Standard spacing is 4″ or 2″ on center. |

Grating Manufacturing Methods

Surface Options (Bearing Bar Type)

Surface Treatment

We provide four finishes for anti-corrosion treatment of carbon steel bar grating:

- Black / Bare Steel: No finish, life is very short, but the price is the cheapest.

- Painted Coat: The anti-rust effect is general and can be any color.

- Electro-galvanized: A small amount of zinc coating, easy to cause slight corrosion in humid environment.

- Hot-dip galvanized: The most commonly used method to provide the best anti-rust effect, strictly in accordance with ASTM A123 or GB/T 13912-2002.

Due to discoloration during welding and manufacturing, stainless steel bar grating usually requires a second cleaning:

- Stainless steel pickling passivation: Soak the entire stainless steel grating in the stainless steel pickling passivation solution, provide a uniform silver-white matte surface.

- Stainless steel electrolytic polishing: The stainless steel grating is immersed in the electrolytic solution that is energized and heated to 75 degrees for 1-3 minutes, can obtain a bright stainless steel surface.

Steel Grating Accessories for Installing

Steel grating accessories are used to install and fix steel grating. They are very necessary. Steel grating accessories have wear resistance, high strength and resistance to stress, rust-proof performance.

Classifications of steel grating accessories:

- Saddle clips: A special bent-clip type fastener for removable bar grating panels.

- G-clips: A special friction fastener can be used with aluminum, stainless steel and galvanized steel.

- Grate fast clips: Grating can be connected by one man only, working from above, without the need to drill the steel or weld on site.

- Weld lugs: Weld lugs may be used for installations where grating is subject to removal.

- Z-clip: This is the most versatile clip anchor. They are especially helpful in holding down riveted grating.

- R-clip: A special formed metal fastener available in various sizes to fit any job.

- Countersunk land: It is available for aluminum grating only. Not available for steel.

- Anchor block: It can be used to fasten permanent or removable grating panels.

Steel Grating Types

Irregular Steel Grating:

Packaging & Shipping

Packaging & Shipping

Hot Searches