NaN / 0

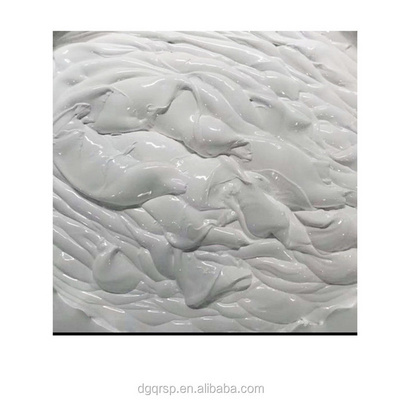

High quality thickness silicone printing ink heat transfer ink for screen printing

Get Latest Price

US$ 19

≥1 Kilograms

US$ 18

≥100 Kilograms

US$ 16

≥500 Kilograms

Quick Details

Type:

Plastisol Ink

Printing Type:

Screen printing

Place of Origin:

Guangdong, China

Brand Name:

QY

Product Details

Product Description

High quality thickness silicone printing ink heat transfer ink for screen printing

Silicone thick transfer and printing materials :

No need middle layer silicone heat transfer operation method

1.Material:

1)Silicone QR-8904A, QR-8904B, color paste, hot melt adhesive.

2)Silicone transfer film: matte and glossy.

2.Using teps:

1)Mix the silicone QR-8904A , QR-8904B according to 1:1, mix evenly, add the

color paste according to 8-10%, mix evenly, screen printing on the release film,

screen printing once, bake 120℃to the surface dry, until the desired effect and

thickness, color.The last time the silicone is not baked, let the hot melt glue.

2)For the last time screen printing silicone no need baking,directly spray

powder .Use the oven for 5 minutes.

3)Screen printing hot melt adhsive 5-8 times, add hot melt powder 20-30%.

Must bake dry each time, do not stick to the plate.(dilute hot melt adhesive with

#783 or cyclohexanone)

4)Bake temperature 140℃ ,put in oven for 30 minutes.

5)Pressing temperature is 150 ℃, positive and back each press 15 seconds,

pressure:4KG. According to the fabric thickness and silicone thickness to

increase the pressing time.

Packaging & Shipping

1KG/5KG/20KG/Bucket.

Our Services

1)We will stick to the principle of ‘customer satisfaction through quality product and customer service through well-established reputation’and do our best to go hand in hand with our customers for a bright future.

2)Considerate pre-sales,sales and after-sales service. Strain every nerve to meet customers demands.

3)Your orders are always well appreciated with great expectation.

Hot Searches