Welcome to contact us for the

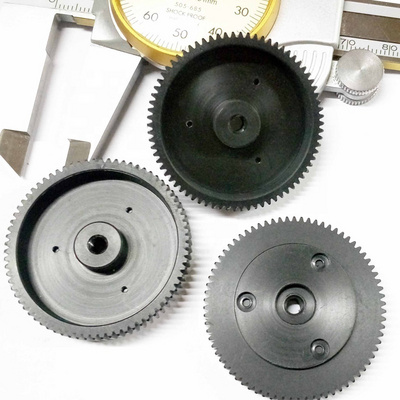

stainless steel bicycle gear hub

.