NaN / 0

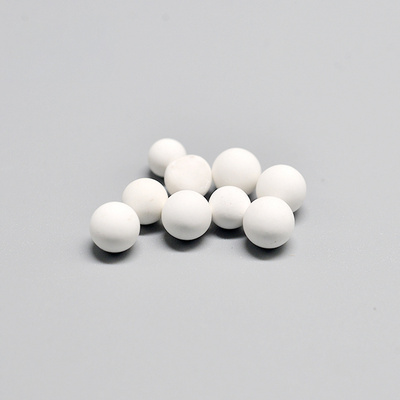

99% Al2O3 High Hardness Alumina Grinding Mill Ceramic Ball Ceramic Beads Abrasive Media for Industry Equipment

Get Latest Price

US$ 1

≥1000 Kilograms

Quick Details

Material:

Alumina Ceramic

Place of Origin:

Jiangxi, China

Model Number:

BS-GCB

Brand Name:

BESTN

Product Details

Product Description

The wear resistance of alumina grinding balls is higher than that of ordinary alumina balls, and it is suitable for grinding media used in ball mills. It does not contaminate the abrasive material when working, so it can maintain the purity and improve the stability of the abrasive material, especially the ceramic glaze. Alumina grinding balls have high density, high hardness and high grinding characteristics, which saves grinding time and expands the grinding space, which can improve grinding efficiency, making it widely used in ceramic raw materials in ceramic factories, cement factories, enamel factories and glass factories. and glaze in a ball mill.

Specification

|

Typical Characteristics

|

|

|

|

|

|

|

||||||

|

Specification

|

65Alumina Ball

|

75Alumina Ball

|

90Alumina Ball

|

92Alumina Ball

|

95Alumina Ball

|

99Alumina Ball

|

||||||

|

Al2O3(%)

|

≥65

|

≥75

|

≥90

|

≥92

|

≥95

|

≥99

|

||||||

|

Fe2O3(%)

|

≤0.5

|

≤0.5

|

≤0.1

|

≤0.1

|

≤0.1

|

≤0.1

|

||||||

|

Moh's Hardness

|

8

|

8~9

|

9

|

9

|

9

|

9

|

||||||

|

Water Adsorption (%)

|

≤0.05

|

≤0.05

|

≤0.02

|

≤0.02

|

≤0.02

|

≤0.01

|

||||||

|

Density (g/cm3)

|

≥2.95

|

≥3.25

|

≥3.55

|

≥3.60

|

≥3.65

|

≥3.8

|

||||||

|

Crush Strength (MPa)

|

≥1650

|

≥1700

|

≥1900

|

≥2000

|

≥2250

|

≥2500

|

||||||

|

Abrasion Loss (%)

|

≤0.03

|

≤0.02

|

≤0.01

|

≤0.01

|

≤0.01

|

≤0.01

|

||||||

|

Appearance Demand

|

|

|

|

|||

|

|

High Alumina Grinding Balls

|

Medium Alumina Grinding Balls

|

Carbonized Alumina Grinding Balls

|

|||

|

Color

|

White

|

White

|

Ash-black

|

|||

|

Crack

|

Not Permission

|

Not Permission

|

Not Permission

|

|||

|

Impurity

|

Not Permission

|

Not Permission

|

Not Permission

|

|||

|

Foam hole

|

Above ф1mm not permission, size in ф0.5mm permit 3 balls

|

|

|

|||

|

Flaw

|

Max. size in ф0.3mm permit 3 balls

|

|

|

|||

Advantages

.

High wear-resistance:

The alumina balls' wear-resistance is higher than the common alumina balls'. When it is working, the ball won't pollute the

grinding materials, so it can keep the purity and improve the stability of grinded materials especially the ceramic glaze.

. High density

High density, high hardness and the high grinding characters save the grinding time, enlarge the smashing room. So it can improve the grinding efficiency.

The alumina balls' wear-resistance is higher than the common alumina balls'. When it is working, the ball won't pollute the

grinding materials, so it can keep the purity and improve the stability of grinded materials especially the ceramic glaze.

. High density

High density, high hardness and the high grinding characters save the grinding time, enlarge the smashing room. So it can improve the grinding efficiency.

Application

1.Grinding ceramic ball is one ideal ball mill grinding media, it can keep the purity and improve the stability of grinded

materials.

2.The alumina grinding ball have been widely used in ball mills as abrasive media for ceramic raw materials and glaze materials in

ceramic factories, cement factories, enamel factories and glasswork.

3.The main features are high density, high hardness and strength, high wear resistance, thermal stability, corrosion resistance

and non-pollution etc.

4.During the abrasive/grinding processes, ceramic balls will not be broken, it will not contaminate the materials to be grinded.

5.Type: According to the content of aluminum oxide: 60-70%, 65-75%, 95%.

materials.

2.The alumina grinding ball have been widely used in ball mills as abrasive media for ceramic raw materials and glaze materials in

ceramic factories, cement factories, enamel factories and glasswork.

3.The main features are high density, high hardness and strength, high wear resistance, thermal stability, corrosion resistance

and non-pollution etc.

4.During the abrasive/grinding processes, ceramic balls will not be broken, it will not contaminate the materials to be grinded.

5.Type: According to the content of aluminum oxide: 60-70%, 65-75%, 95%.

Packing & Delivery

About us

Pingxiang Bestn Chemical Packing Co., Ltd was established in 2007, It is a professional manufacturer and exporter that has more than 10 years experience in Chemical Packing. We are located in Hi-Tech Industrial Park, Development area, Pingxiang city, Jiangxi Province, with convenient transportation access. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.Our main products are molecular sieve, activated alumina, ceramic ball, honeycomb ceramics, Plastic lamella clarifiers, MBBR Media, random and structured chemical packing in ceramic, plastic and metal material, can be used in all types of petrochemical chemical processes and environmental application.Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction. Besides, we have received ISO9001: 2008 certificate, SGS report, etc. As a result of our high quality products and outstanding customer service, we have gained a global sales network reaching seven Continents.Since its foundation, our company keeps living up to the belief of "honest selling, best quality, people-orientation and benefits to customers" We are doing everything to offer our customers with best services and best products. We promise that we will be responsible all the way to the end once our services begin.If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with you, also warmly welcome to visit our factory.

Hot Searches