NaN / 0

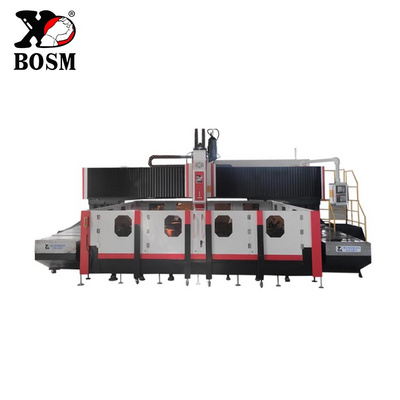

Raintech CNC High Speed Gantry Moving Type Steel Plate Metal Flange Drilling Machine BT Spindle Boiler Sheet Drilling Machine

Get Latest Price

US$ 53000

≥1 Sets

US$ 52000

≥3 Sets

US$ 51000

≥5 Sets

Quick Details

type:

Planar Drilling Machine

Max. Drilling Dia. (mm):

50mm

Range of Spindle Speed(r.p.m):

30 - 4500 r.p.m

Place of Origin:

Shandong, China

Product Details

High Speed Gantry Moving Type

CNC

Steel Plate Metal Flange Drilling Machine for

boiler sheet

steel structure

Product Description

Advantage and Highlight:

1.Steel plate welded bed workbench.

2.Honeycomb mobile gantry .

3.Double screw synchronous drive system.

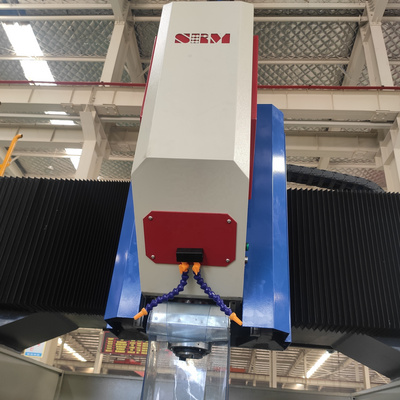

4.Servo motor power head.

5.BT40/50 precision spindle.

Product Parameters

|

Model

|

|

PHD1616

|

PHD2016

|

PHD2020

|

|||

|

Processing range

|

LxW(mm)

|

1600*1600

|

2000*1600

|

2000*2000

|

|||

|

|

Max. Thicknesss(mm)

|

15-100

|

|

|

|||

|

Slide Ram type power head

|

Number of spindle ( pcs )

|

1

|

|

|

|||

|

|

Spindle model

|

BT40/BT50

|

|

|

|||

|

|

Spindle speed(r/min)

|

30-4500

|

|

|

|||

|

|

Feed stroke (mm )

|

260

|

|

|

|||

|

|

Tapping diameter (mm )

|

M20

|

|

|

|||

|

Motor Power(KW)

|

Spindle Servo Motor

|

7.5/11

|

|

|

|||

|

|

X axis

|

2x2.3

|

|

|

|||

|

|

Y axis

|

2.3

|

|

|

|||

|

|

Z axis

|

2.3

|

|

|

|||

|

Positioning accuracy ( mm)

|

|

0.1

|

|

|

|||

|

Repeated positioning accuracy ( mm )

|

|

0.08

|

|

|

|||

|

Control method

|

|

Siemens 808D CNC system/PLC+host computer

|

|

|

|||

|

Weight (T)

|

|

5.5

|

6.6

|

7.2

|

|||

|

Dimensions (mm)

|

|

3800x2050x2750

|

4200x2450x2750

|

4200x2850x2750

|

|||

Finished workpiece

The machine is mainly used for drilling and milling of steel structure,irontower,bridge,

mechanical processing and other industries,such as connectingplate and floor board,drilling and milling of tubes,baffles and flanges inindustries such as boiler petrochemical,pressure vessel and so on; drillinoholes,blind holes,step holes,chamfering and light milling

Product Details

The bed&worktable are whole welded bysteel plates. In order to eliminate theresonance generated during drilling andprolong the service life of the alloy drilthe integrated structure of the bed andworktable is adopted.

The movable gantry is welded withhigh-quality steel plate, honeycombstructure, and the stress is removed by twotempering heat treatments

The movable gantry is welded withhigh-quality steel plate, honeycombstructure, and the stress is removed by twotempering heat treatments

Double screw synchronous drive system,stable performance, fexible movementand accurate positioning

Equipped with a centralized lubricationdevice, which can automatically lubricatevarious transmissions such as guide railslead screws and bearings

Manufacturing Process

We have cooperated with experienced shipping forwarders for many years, they arrange the shipment. No matter by express, by air or by sea, we will track the course of the goods all the way, to make sure goods arrive at you on time and in good condition.

Company Introducation

Why Choose Raintech SANS?

CERTIFICATE

International exhibitions

Customer visits

FAQ

♥1.How to operate the machine ?

We will deliver English manual and video with the machine to you. lf you still need our help, please contact us.

♥2.

If some problems happen to this machine during warranty period, what should I do?

We will supply free charge of spare parts and regularly maintenance service during machine warranty period if machine have some problems. So any doubts, just let us know, we will give you solutions.

♥3.

Does the machine can be customized according to my requirements ?

Yes,

we have a strong technical team and have rich experience.

♥4.

What about the package and shipment ?

The machine will be packaged by multilayer plastic wrap for anti-humidity on the sea. The strong steel wire roops will be used for fix the machines in container to avoid any damage in transportation.

Hot Searches