NaN / 0

Industrial Alkaline Water Machine Equipment for Alkaline Water

Get Latest Price

US$ 13500

≥1 Sets

Quick Details

Place of Origin:

Jiangsu, China

Brand Name:

King machine

Material:

Wooden case

Weight:

Depends

Product Details

Water Treatment

1 / Water treatment equipment description.

The methods of water treatment include physical treatment and chemical treatment.

The physical method includes the use of various filter materials with different pore sizes, and the impurities in the water are excluded by adsorption or blocking. The most important adsorption method is adsorption by activated carbon, and the blocking method is to pass water through the filter material to make the volume. Larger impurities cannot pass, resulting in cleaner water. The chemical method uses various chemicals to convert impurities in water into substances that are less harmful to the human body, or concentrates impurities. After the impurities in the water are collected, the volume becomes larger, and the impurities can be removed by filtration.

RO Reverse osmosis system

Hollow ultrafiltration

EDI Ultra-pure water system

Product Details

Application field.

(1)

Power industry

: boiler feed water, cooling dam;

(2)

Electronics industry

: ultra-pure water for semiconductor industry, cleaning water for integrated circuits, and formula water;

(3)

Food industry

: formula water, production water;

(4)

Pharmaceutical industry

: process water, preparation water, washing water, water for injection, and sterile water;

(5)

Beverage industry

: formula water, production water, washing water;

(6)

Chemical industry

: production water, wastewater treatment;

(7)

Drinking water project

: preparation of ultrapure water and purification of drinking water;

(8)

Petrochemical industry

: advanced treatment of oilfield injection water and petrochemical wastewater;

(9)

Seawater desalination

: production and domestic water in island areas, coastal water-deficient areas, ships, seawater oil fields, etc.;

(10)

Environmental protection field

: recovery of precious metals and water in electroplating rinse water to achieve zero or micro emissions.

Reverse Osmosis.

Reverse osmosis is a membrane separation technique that uses pressure as a driving force by selecting a function of permeating (semi-transmissive) membrane. When the pressure applied in the system is greater than the osmotic pressure of the aqueous solution, the water molecules continuously permeate the membrane. The impurities flowing into the central tube through the product water channel and then flowing out of the water at one end, such as ions, organic matter, bacteria, viruses, etc., are trapped on the water inlet side of the membrane, and then flow out at the concentrated water outlet end, thereby achieving the purpose of separation and purification.

Reverse osmosis water treatment equipment mainly has the following applications:

(1) The production of pure water and ultrapure water for industrial production such as monocrystalline silicon semiconductor integrated circuit blocks, picture tubes, glass bulbs, and liquid crystal displays.

(2) Water for the pharmaceutical industry: pharmaceutical, formulation process water, medical hemodialysis, biochemical analysis, infusion, etc.

(3) To prepare thermal and thermal power boilers, softened water and demineralized pure water required for medium and low pressure boiler feed water in factories and mines.

(4) The drinking water, distilled water, natural water, mineral water, mineralized water, liquor production, white wine blending with pure water, beer saccharification feed water and pure draft beer filtration are prepared.

(5) Hotel, building, community quality water supply network system and swimming pool water purification.

(6)Prepare the electroplating process with deionized water, battery (battery) production process of pure water, automotive, household appliances, building materials, surface coating, cleaning pure water, coated glass with pure water, textile printing and dyeing process required to remove hard brine.

(7) Petrochemical industry such as chemical reaction cooling, chemical agents, fertilizers and fine chemicals, cosmetics manufacturing process with pure water.

UF water treatment equipment.

Ultrafiltration water treatment equipment is a membrane separation process with pressure as the driving force. The micropores of the membrane surface can be used to intercept particles and impurities between 0.002-0.1μm in diameter, which can effectively remove colloid, silicon, protein and microorganisms in water. And macromolecular organics.

Equipment use.

Pure water and ultrapure water equipment; medical sterile pyrogen-free water equipment, industrial beverages, drinking water, mineral water purification, industrial separation, concentration, purification, industrial wastewater treatment, electrophoretic paint, electroplating oily wastewater treatment.

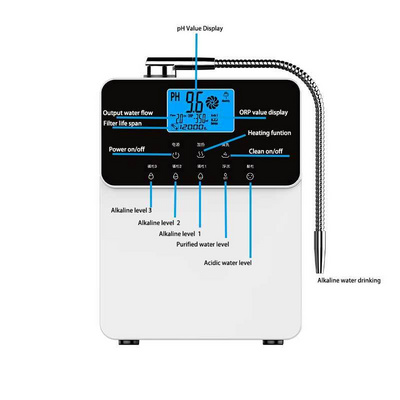

Alkaline water treatment.

Ultrapure water system.

About King Machine

About King Machine

1 / Standardized workshop of total 20,000 square meters.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

King Machine Factory

<1> Standardized workshop of total 20000 square meters.

Different types of processing units, such as water jet cutter, plasma cutter, laser cutter, CNC machine from Taiwan chevalier &Korea Daewoo, ensure the precision of parts.

Different types of processing units, such as water jet cutter, plasma cutter, laser cutter, CNC machine from Taiwan chevalier &Korea Daewoo, ensure the precision of parts.

<2>The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechanical stability.

<3>Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<4>Engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers’ requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

<3>Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<4>Engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers’ requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

Certificate &Patent

International certification, National Certificate of equipment verification, and more than 30 invention patents are done in King machine .

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark

registration,etc.

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark

registration,etc.

King Machine Serivce

*7/24 Online Service::Machine running video / Watch our factory online / More service contact us

*Sucessful Beverage Plant::Supply a running beverage line in your country , you can see machine runing directly.

*Installation / Debug / Training:

1 - We will arrange seasoned technician for equipments installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

*After-sales Service:

1 - After checking, we offer 12 months as a quality guarantee, free offer wearing parts and offer other parts at the lowest price.

2 - If you could not solve the problems, we will arrange a technician to your factory solving the problems.

3 - After quality guarantee, we offer technical support and after-sales service.

*Sucessful Beverage Plant::Supply a running beverage line in your country , you can see machine runing directly.

*Installation / Debug / Training:

1 - We will arrange seasoned technician for equipments installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

*After-sales Service:

1 - After checking, we offer 12 months as a quality guarantee, free offer wearing parts and offer other parts at the lowest price.

2 - If you could not solve the problems, we will arrange a technician to your factory solving the problems.

3 - After quality guarantee, we offer technical support and after-sales service.

Customers Feedback

King Machine is a professional manufacturer of beverage machinery in China.With the scientific progressive conception of rapid

introduction, we make our machinery cover all over the overseas market. We have been producing our goods with mature techniques and first-class quality. We warmly welcome customers all over the world to visit our manufacture.

Customer Reviews

Cooperative Customer Brands

FAQ

HOW TO FIND KING MACHINE?

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

● Visit exhibition in different countries

● Send King Machine an request and tell your basic inquiry

● King Machine sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to King Machine site

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed& research team,we

can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE KING MACHINE HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to

ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF KING MACHINE!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or

instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

● Visit exhibition in different countries

● Send King Machine an request and tell your basic inquiry

● King Machine sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to King Machine site

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed& research team,we

can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE KING MACHINE HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to

ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF KING MACHINE!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or

instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

Hot Searches