NaN / 0

Mixed bed ion exchanger ion exchange systems cation anion dural bed DI water machine water deionizer machine system plant

Get Latest Price

US$ 4000

≥1 Sets

Quick Details

Core Components:

Auto generator, mixed bed ion exchange

Place of Origin:

Guangdong, China

Brand Name:

JISHUI

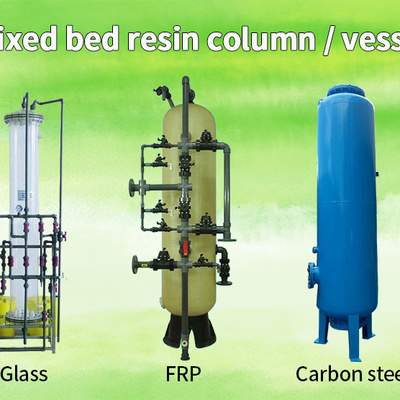

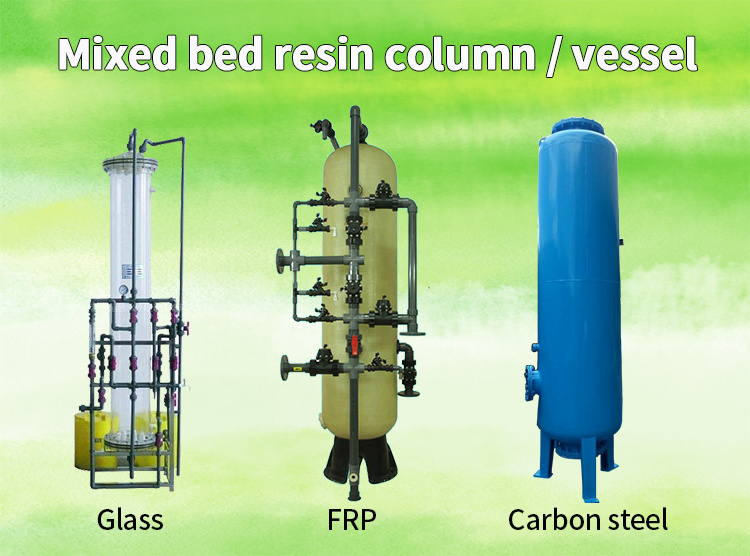

Material:

plywood case, UPVC or stainless steel

Product Details

Mixed bed ion exchanger ion exchange systems cation anion dural bed DI water machine water deionizer machine system plant

Product Description

Please Attention

HY FACTORY OFFER YOU :

1: FACTORY DIRECT PRICE.

2: NICE QUALITY.

3: ONLINE PAYMENT.

4: SUPPORT REFUND AFTER YOUR INSTALLED THE PLANT IF THERE ARE ANY PROBLME.

5: AFTER SALES SERVICES 24/7

6. Letters patent

7. ENGINNER CAN BE OVERSEA INSTALLNATION

We have 2 factories +300 workers+ Qualified engineer+ Engineer Overseas service

deionized water machine Process function description

1.Deionized water machine use automatic control and semi-control .Pretreatment parts can adopt fiber glass or stainless steel material.

2.Water deionizer machine has protected when no power, poor power, larger electrical current, leakage, short circuit.

3.Di water machine is compact, easy installation.

4.Industrial deionized water machine equipped with manual and auto control based on user needed.

5. Haiyuan di water machine produce as per ISO and SGS standard and main parts accessories have obtained CE certification.

6. All the plants will be commissioning well. Make sure don't have any problem when arrived site.

7.What we provide not only the good products, but also our whole team, the quality, experience, and service.

W ate r deionizer machine

·A mixed bed ion exchange in water treatment uses two ion exchange regenerative systems formed in beads shape. It allows the cation and anions resin beads to mix together to remove impurities to produce high-quality water.

·The mixed bed ion exchange acts as a deionizer and effectively removes the ions present in the water .

FEED WATER QUALITY AND TREATMENT TECHNOLOGY OF deionized water machine

How di water machine to work

· Water deionizer machine is a vessel filled with a mixture of cation exchange resin and anion exchange resin. During service, water flows through this resin mixture. Cations dissolved in the water are then exchanged for hydrogen ions (H+), while anions dissolved in the water are exchanged for hydroxide ions (OH-). Hydrogen ions and hydroxide ions react to water.

·

With increasing service life, the ion exchange resins deplete. Depleted mixed bed resins are regenerated, usually with both hydrochloric acid (HCl) and sodium hydroxide (NaOH). With each regeneration, potentially acidic or alkaline waste water is produced, which may need to be neutralised. In case of smaller mixed bed exchangers, the ion exchange resin is sometimes also discarded and exchanged once depleted, rather than regenerated.

· Usually, water deionizer machine is used either as a last polishing step downstream of another demineralisation process, or as a working mixed bed for demineralisation of already partly demineralised or low-TDS water (e.g. condensate).

Feature

benefits of water deionizer machine

-

water deionizer machine use automatic or semi-control.

- High salt rejection rate

-

DI water machine be protected while no power, poor power, larger electrical current, leakage, short circuit.

-

Industrial deionized water machine produce as per ISO and SGS standard and main parts accessories with CE certification.

-

deionized water machineCan supply oversea installation and commissioning.

- benefits of deionized water purify machine is compact, easy installation.

Process flow

- Source tank →Feed water pump → multi-media filter(sands filter) → active carbon filter → water softener ( or inhibitor dosing ) →PP filter→ high-pressure pump →RO system→PH adjust system →RO tank →EDI booster pump →UV sterilization →PP filter→ EDI system →EDI tank → transfer pump → outlet water

Hot Searches