NaN / 0

Customized Heavy Duty Selective Pallet Rack Boltless Adjustable Metal Frame Garage Shelving 5 Layer Storage Shelf Rack

Get Latest Price

US$ 1.1

≥3000 Kilograms

US$ 1.05

≥10000 Kilograms

US$ 0.98

≥40000 Kilograms

Quick Details

Type:

Selective Pallet Rack

Material:

Q235B steel

Feature:

Corrosion Protection

Use:

Warehouse Rack

Product Details

CE certificated heavy duty warehouse picking equipment storage rack

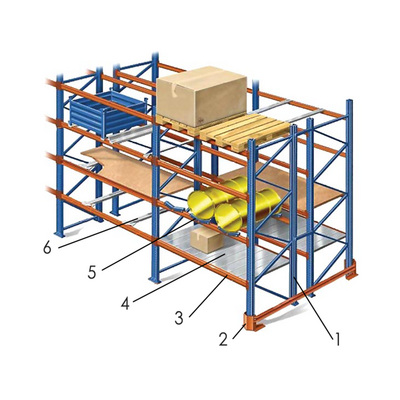

Standard Pallet Rack

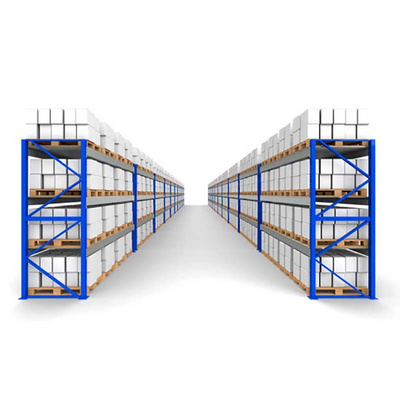

Standard Pallet Rack is the most common form of storage rack. Pallets of materials are placed directly on the rack system by a forklift. Each load in pallet racks is readily accessible , making the 100% selective storage rack systems are both economical and efficient . Pallet rack designs come in numerous configurations to handle any storage need and can be easily expanded as your company grows. They are well built and extremely durable.

Warehouse picking equipment

Features of pallet racking system:

1. Pallets can be located, accessed and moved individually.

2. Rapid handling of almost all types of palletized goods.

3.

Different sizes, various specifications and colors are available according to different needs.

4.

Easy access to installment and simple to adjust by the pitch of 75mm or 76mm.

5. Strength and rigidity prevents compression damage to goods.

6. Bottom level of pallets can be stored on the floor, lowering structure costs.

Three upright rack is also acceptable, then the depth can be max 2400mm.

|

Load Capacity & Dimension: |

|

| Surface treatment |

|

|

Material: |

High-quality Q235B steel plate purchased from the big steel Group in China. |

|

Others: |

|

Quotation

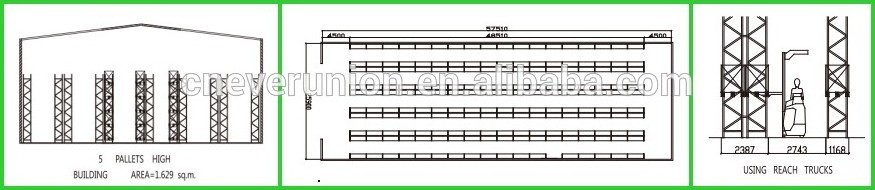

Please inform us the listed information for a quick quotation of pallet rack:

1) drawings of your warehouse or rack system if possible

2

)

Your pallet size:

Height (with goods)*Depth*Length? Which side is for forklift entry?

3 ) How many start bays and add on bays you want.

4 ) Clear warehouse height or Max forklift lifting height

5 ) Loading capacity of each level

6) Aisle width needed for forklift operation, as common 3000mm

We can provide free and professional warehouse rack Auto CAD drawing design based on your these above info, to solve your warehouse storage solutions.

Or pls let us know your rack size(H*D*W), nons of level, loading each level, qty of starter rack + Add-on rack.

Related Products

Hot Searches