NaN / 0

Fully Automatic Metal Powder Coating Line for Aluminium Profile

Get Latest Price

US$ 21000

≥1 Sets

US$ 18800

≥20 Sets

US$ 10999

≥1999 Sets

Quick Details

Machine Type:

powder coating line, Spray Booths, Curing oven, Coating Equipment

Place of Origin:

Zhejiang, China

Brand Name:

COLO

Voltage:

100-240V

Product Details

Products Description

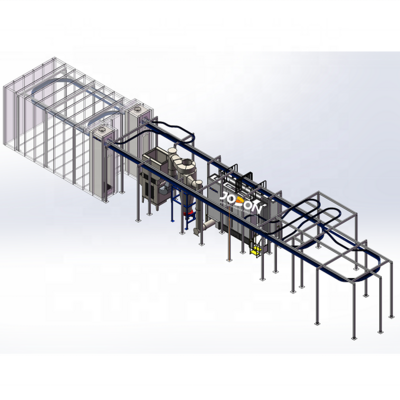

Automatic powder coating line includes

complete aluminium profile powder coating line, powder coating plants, powder coating system, coating machine, curing tunnel, overhead conveyor system , spraying booth, conveyor systems and pretreatment system and so on.

This automatic powder coating line is Ideal for long length or heavy workparts, such as aluminum profiles, metal frames, furniture, etc.

Features of Automatic Powder Coating Line

1) Conveying system: closed-circuit overhead conveyor for powder coating.

2) Automatic powder booth: with cyclone or filter recovery stage, made of plastic material

3) Automatic spray gun and reciprocator: for consistent and uniform powder coating

4). Powder supply center: maximize the performance of powder feeding, cleaning and control

5) Curing tunnel: uniform heating temperature ensure quality cured results

2) Automatic powder booth: with cyclone or filter recovery stage, made of plastic material

3) Automatic spray gun and reciprocator: for consistent and uniform powder coating

4). Powder supply center: maximize the performance of powder feeding, cleaning and control

5) Curing tunnel: uniform heating temperature ensure quality cured results

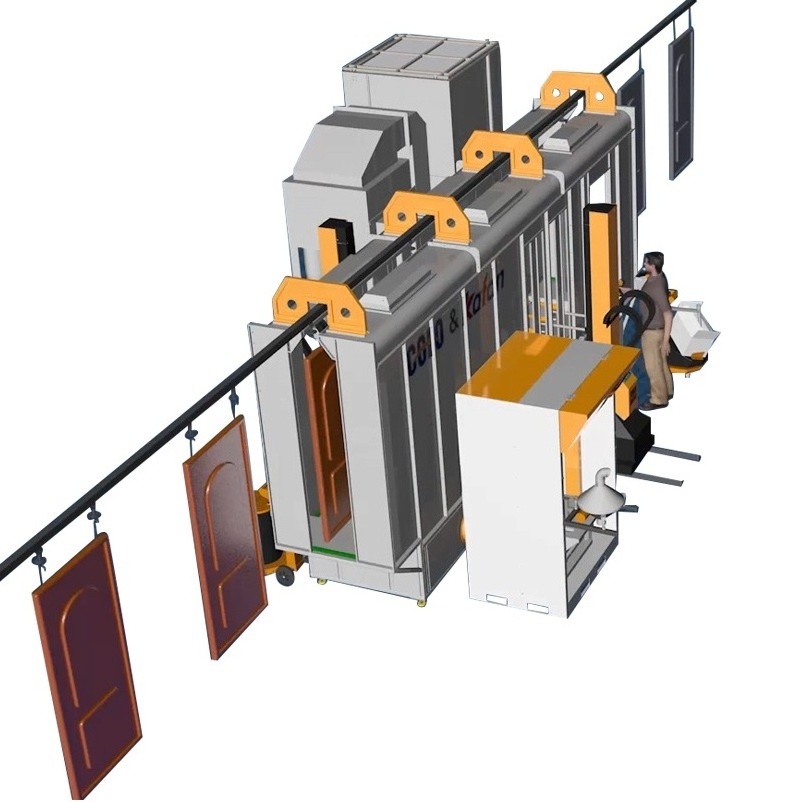

COLO-2000D Automatic Powder Coating Reciprocator

COLO-2000D Reciprocator is designed for consistent and uniform coating in automatic production line. spraying guns are mounted on an arm extended from a carriage, whose movement is programmed in various speeds & strokes to suit conveyor speed & object height respectively.

|

Model

|

COLO-2000D

|

|

Power Supply

|

AC 220V/110V 50-60hz

|

|

Motor Power

|

0.75 kW

|

|

Speed

|

0-0.8m/s(0-50m/min)

|

|

Acceleration

|

1 m/s

|

|

Max. Loading Capacity

|

25 kg

|

|

Controller

|

Digital

|

|

Motor

|

Frequency Adjustable

|

|

Stroke

|

1.5m / 2m / 2.5m

|

|

Qty of Spray Guns Loading

|

2-12 pcs

|

Overhead Conveyor Powder Coating Line

Overhead conveyor system is the most commonly used solution for wet paint or powder coating finishing. The type of conveyor selected for your operation will depend on the weight , size and even the shape of the items being transported. We provide conveyor systems based on your specific products , designs varies from product weight , size and even the shape.

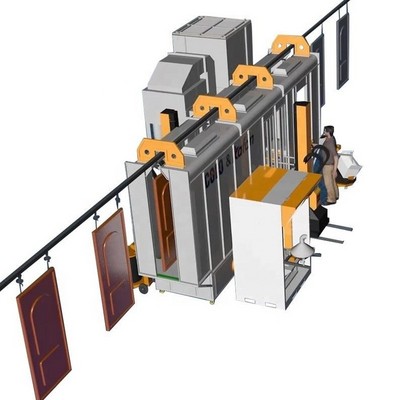

Our automatic powder coating booth constructed with plastic booth chamber and stainless steel cyclone, which is specially built for multi-color coating lines. As the booth wall is made of anti-static plastic it does not attract powders which minimizes powder accumulation on the surface. It is the best choice for quick color change and high powder recovery demands.

Industrial Powder Coating Cure Oven

This powder coating oven is designed for curing longer workparts in batches. It is recommended to take gas or diesel as fuels, which fearures higher heating efficiency and lower energy expense.

COLO provides standard and custom powder paint curing ovens for every industrial needs, and built with top-quality components that extends to longest lifespan.

COLO provides standard and custom powder paint curing ovens for every industrial needs, and built with top-quality components that extends to longest lifespan.

Customer Case

Powder coating line is ideal for continuous batch production, based on manual operation with overhead conveyor, includes pass thru powder coating booth and curing ovens, as well as manual powder painting machine.

It will help user expand output, form mass production and reduce cost in order to make products’ price more competitive.

It will help user expand output, form mass production and reduce cost in order to make products’ price more competitive.

Customer Feedback

Recommend Products

Product packaging

Hot Searches