NaN / 0

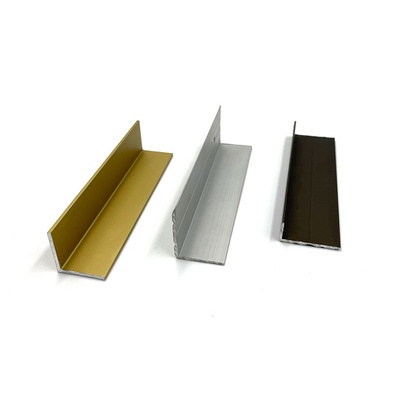

Top-selling Carpet Aluminum Transition Edge Strip Trim, Metal Floor Transition Strip

Get Latest Price

US$ 2.8

≥2000 Kilograms

Quick Details

After-sale Service:

Online technical support, Free spare parts

Project Solution Capability:

graphic design, Cross Categories Consolidation

Application:

Hotel

Design Style:

Modern

Product Details

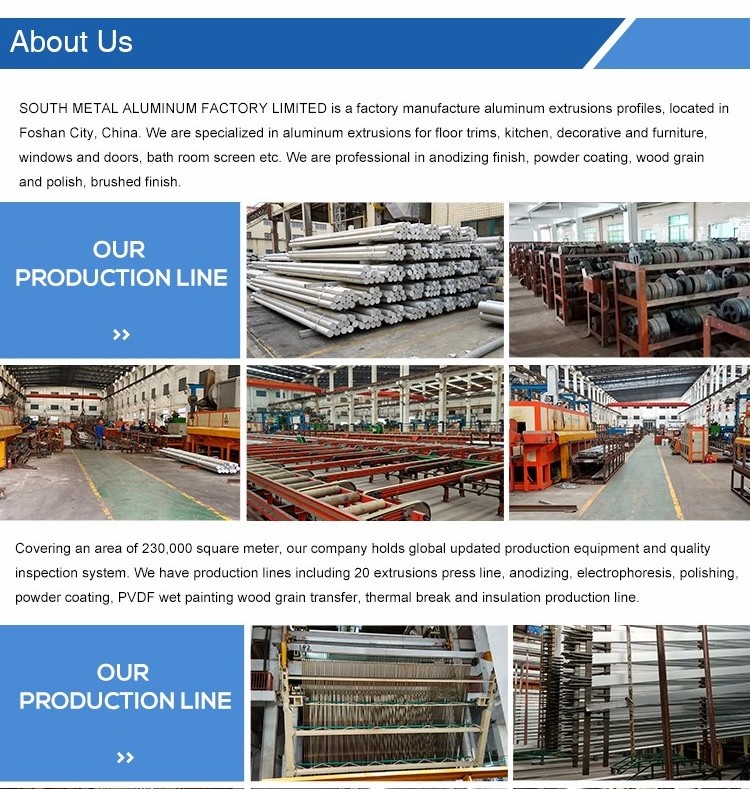

Product Description of Professional manufacture inside tile corner trim decorative chrome tile trim

1.Connect the gap between wall and floor perfectly.

2. Used for decoration, office, hotel, apartment etc.

3. Flame retardant, waterproof, mositure resistance, abrasive resistance, stain resistance and durable

4. Smooth surface, no toxic and enviromental protection.

5. Easy installation.

6. Color: silver, black, champagne, titanium, gold, copper, wooden, stone and at costomers' request.

7.Surface treatment: Anodizing, powder coating, wood Grain, Wire Drawing, Polishing, Cataphoresis.

8.Mould: free and at cusotmers' request

9.Skirting board cover sample: free

HOME-1

1. Basic information

a. Aluminum alloy: 6000 series, such as 6063 T5, 6061 T6, 6082 T6 etc.

b. The best online price of aluminum profiles supplier from China. And High quality 10 years Guaranteed.

c. Products with good finish clean and smooth, no scratch, no spot,

d. Lead time, 20 days and timely delivery.

e Aluminum profiles for windows, doors, curtain wall as well as industrial purpose.

Standard aluminum pipe, tubes, rectangular shape

Aluminum profiles for market in Kuwait, Mauritius, Nigeria, Ghana

Aluminum profiles for furniture and kitchen, wardrobe, skirting, tile trim

Aluminum profiles for handrail section and showing shelf sections

2,Meterial: Alloy 6063 T5

|

Chemical Composition |

6063 T5 |

|

|

|

|

||||

|

Si |

Fe |

Cu |

Mn |

Mg |

Zn |

Ti |

Cr |

Others |

total others |

|

0.2-0.6 |

M.0.35 |

M. 0.1 |

M. 0.1 |

0.45-0.9 |

M. 0.1 |

M. 0.1 |

M. 0.1 |

M. 0.05 |

0.15 |

|

Mechanical property |

|

|

|

|

|

||||

|

Yield Strength |

Tensile Strength |

Extensibility |

hardness |

|

|

|

|||

|

110Mpa |

160Mpa |

8% |

8 HW |

|

|

|

|||

HOME-2

3. Surface treatment for aluminum profiles

a.Anodizing finish

b.Electrophresis finish

c.Powder coating

d. Wood

e. Polished

f. PVDF coating

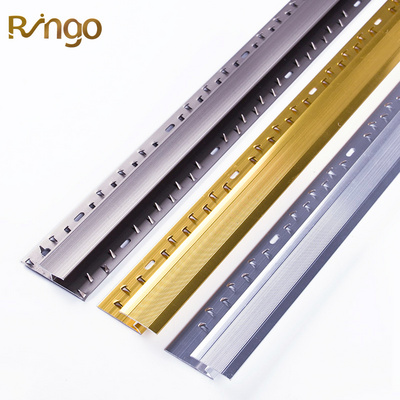

4. Manufacture technological process

Chief manufacture technological process:

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

equipment/workshop

(1) 20 extrusion production lines from 600T to 3600T;

(2) 3 horizontal billet casting production lines;

(3) 2 anodizing and electrophoresis production lines;

(4) 3 spraying production lines;

(5) 3 thermal insulation production lines;

(6) 1 wood grain production line.

The comprehensive production capacity has exceeded 50,000 tons.

Hot Searches