NaN / 0

Good Selling Grass Feed Pellet Line Cattle Mixer Pakistan Pallet Making Machine

Get Latest Price

US$ 8000

≥1 Sets

Quick Details

Max. Capacity:

1 ton/h

Place of Origin:

Henan, China

Brand Name:

xinhengfu

Voltage:

380, 380v, 50hz, 3phase

Product Details

Good Selling Grass Feed Pellet Line Cattle Mixer Pakistan Pallet Making Machine

Product Description

Powder Feed Line features

1. Simple and flexible arrangement, save factory area.

2. High performance dust collection system, no dust flying, environment friendly.

3. Low energy consumption, low noise.

4. Auto-control box

5. Easy operation

6. Low cost.

7. Grinding, conveying, mixing system are integrated.

8. It can produce powder feed. it’s suitable for livelock, poultry and aquatic product farms to produce feed.

9. We can design manual and full –automatic complete machine according to your demands, and responsible for the installation and adjustment of machine, otherwise we can supply you free wearing parts for one year .

Feed Mixer parameters

| Model | SSHJ0.5 | SSHJ1 | SSHJ2 | SSHJ4 | SSHJ7 | |

| Transmission Type | Chain drive | Chain drive | Chain drive | Chain drive | Chain drive | |

| Power(kw) | 5.5 | 11 | 18.5 | 30 | 45 | |

| Machine dimensions(mm) | 1900*1700*1250 | 2400*1900*1500 | 2500*2300*1800 | 3275*2720*2155 | 3469*3110*2410 | |

| Capacity(t/batch) | 0.25 | 0.5 | 1 | 2 | 3 | |

| Mixing uniformity CV(%) | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | |

| Mixing time | 0.5-2min | 0.5-2min | 0.5-2min | 0.5-2min | 0.5-2min | |

| Weight (kg) | 1280 | 2150 | 3175 | 5960 |

8780

|

|

Feed Crusher parameters

| Model | SFSP56*36 | SFSP56*40 | SFSP708*40 | SFSP66*60 | SFSP968*40 | |

| Rotor diameter (mm) | 560mm | 560mm | 708mm | 660mm | 968mm | |

| Crush room width (mm) | 360mm | 400mm | 400mm | 600mm | 400mm | |

| Rotate Speed (r/min) | 2940 | 2950 | 2970 | 2970 | 1480 | |

| Number of Hammers | 40 | 40 | 80 | 96 | 44 | |

| Sieve Dimension | 355*800 | 395*800 | 1050*395 | 1800*355 | ||

| Capacity (t/h) | 1-3 | 2-5 | 3-8 | 5-8 | 6-10 | |

| Main Power (kw) | 22 | 37 | 55 | 55-75 | 90-110 | |

| Weight (kg) | 605 | 760 | 1125 | 1250 | 2570 | |

| Dimension (L*W*H) | 1430*800*1050 | 1600*800*1050 | 1900*1000*1450 | 2100*1000*1200 | 2200*1800*1900 | |

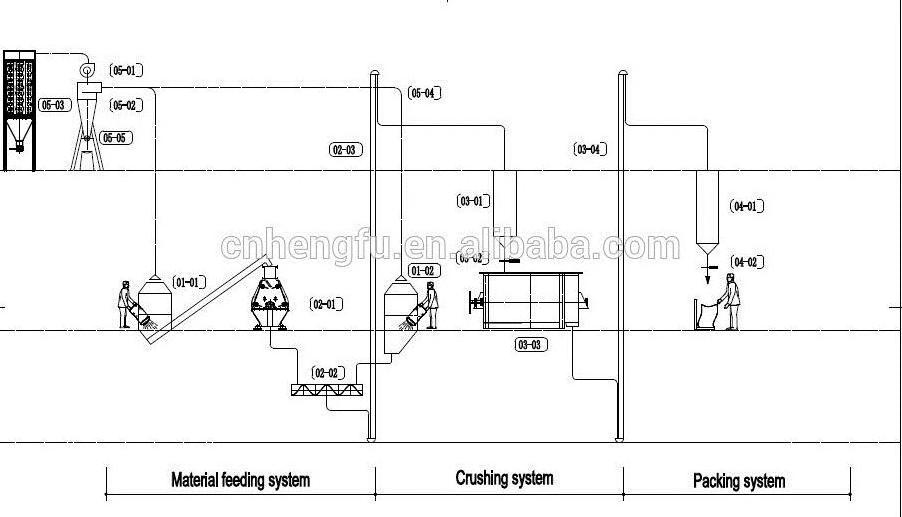

5t/h Animal powder feed plant equipment diagram

---Receiving and cleaning section of raw material

As we received the material, there will be possibility of having unwanted material such as iron pieces, jutes threads, oversize pieces which can jam the silos\ system. So for cleaning we use a pre-cleaning machine. Then these pre-cleaned materials are transpired to silos through mechanical conveyors and elevators.

---Grinding section

Grinding system is a process of breaking solid ingredients to a required size. Finer the material higher will be the surface area exposure to heat and moisture to accomplish the gelatinization in conditioning. A fine granding material can transfer his maximum energy to the animal as compared to a course grinded material. It is a very energy consuming process.

---Mixing section

Mainly use mixer to mix raw material fully. Multiform liquid adding system is available.

---Packing section

In the finally packing process, which is effectively handled by automatic packing machine .

Related Products

Feed production line

flat die type grass pellet mill

powder feed plant pellet feed plant

Pellet feed machine

flat die pellet mill ring die pellet mill

Feed grinder

water drop hammer mill 9fq feed grinder

Feed mixer

single shaft mixer double shaft mixer

Feed mixer and grinder

Animal farm equipment

Packaging & Shipping

Specialized design of wooden box packing, ensure that the goods are not damaged,; Container transport.

Our Services

Pre-sale service:

1.Provide our client with investment guide for free.

2.Provide our client with evaluation investment scheme for free

3.Free visit to our factory.

4.Design of production line scheme is provided for free.

In-sale service:

1. Experienced workers are sent to provide track service when equipment is transported.

2. Experienced technicians or engineers will be sent for on-site installation, adjustment and technical devices according to clients' engineering requirement.

3. "Operating instruction manual", equipment assembly drawings and wearing parts list in duplicate will be provided for free.

Post-sale service:

1. On the premise that equipment is operated correctly and in warranty period, we accept repair, exchange, and return items.

2. We provide permanent favorable spare parts for our clients.

3. We provide permanent technology support and related help.

² Professional engineering design

² E arliest delivery ,high quality with best price

² Safe and efficient transport services

² Efficient installation guide can send video installation and operation

² One year guarantee for whole machine, except the wearing parts .

² We can provide engineers available to service machinery overseas.

² 24 hours technical support by E-mail or telephone.