NaN / 0

polyurethane spray foam closed cell pu foam chemicals for spray insulation

Get Latest Price

US$ 1.5

≥500 Kilograms

Quick Details

CAS No.:

MDI ISO

Other Names:

polyol and iso-cyanate MDI ISO

MF:

PU foam

EINECS No.:

PU insulation foam

Product Details

Product Description

Product Description of Double Component Polyurethane Foam Material

pu polyurethane spray foam closed cell raw material for spray insulation

DQT-501C is spray blend polyols, blowing agent is 365mfc/245fa instead of HCFC-141B, it reacts with iso-cyanate to produce foam which has excellent performances, which are as follows:

1) fine and uniformity cells

2) low thermal conductivity

3) good low temperature dimensional stability.

It applies to all kinds of thermal insulation engineering which uses the spray technology, such as cold rooms, pots, large-scale pipelines and construction metope etc.

Parameter

Parameter of Double Component Polyurethane Foam Material

pu polyurethane spray foam closed cell raw material for spray insulation

Physical Properties

|

Appearance Hydroxyl Value mgKOH/g Dynamic Viscosity (25 ℃) mpa.s Specific gravity (20 ℃ ) g/ml Storage Temperature ℃ Storage Stability month |

Pale yellow to brown viscous liquid 200-300 100-200 1.12-1.20 10-25 6 |

Recommended Ratio

|

|

pbw |

|

DJD-105 blend polyols iso-cyanate |

100 100-105 |

Reactivity Characteristics

(The temperature of the system is 20℃,and the exact value varied depending on processing condition)

|

Cream Time s Gel Time s |

3-5 6-10 |

Foam Performances

|

items |

Test Method |

Index |

|

Spray Density Closed-cell Rate Initial Thermal Conductivity(15℃) Compressive Strength Adhesive Strength Elongation at break Dimentional Stability 24h -20℃ 24h 70℃ Water Absorption Oxygen Index |

GB 6343 GB 10799 GB 3399 GB/T8813 GB/T16777 GB/T9641 GB/T8811

GB 8810 GB 8624 |

>40kg/m3 ≥90% ≤24mW/(m.K) ≥150kPa ≥120kPa ≥10% ≤1% ≤1.5% ≤3% ≥26 |

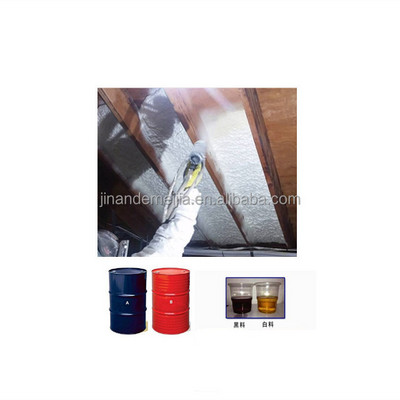

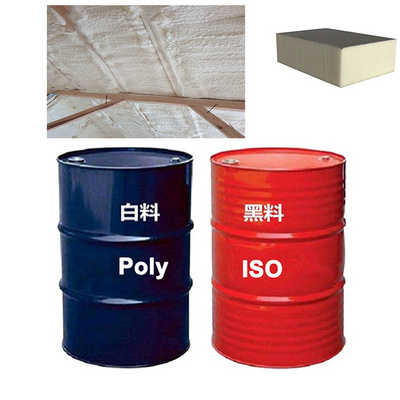

Detailed Images

Images of Double Component Polyurethane Foam Material

pu polyurethane spray foam closed cell raw material for spray insulation

Advantage of polyurethane spray foam insulation machine

PU Foam Polyurethane insulation raw material

1. The cylinder solenoid valves are all imported, more expensive than the common cylinders.

2. Free on-line training for technology, full way tracking and testing, high sales volume.

3. All accessories are supplied by the original manufacturer and are available to customers at cost price

4. The high pressure pipe is anti-corrosion.

5. The temperature control meter is dual display, which can display the actual temperature and the set temperature. Other manufacturers can only display the set temperature and can not see the actual temperature. Red meter shows the actual temperature, green shows the set temperature

6. The operation temperature control panel is independent module which can be replaced separately. For other factories ,there is an integrated board next to the temperature control table,if one is broken ,others temerature meters all should be changed .

Learn to maintain machine :

Main Machine Daily Use and Maintenance:

1 Replace DOP in oil cup of primary-secondary pump daily;

2 When equipment stops running, swerve Start/Reset switch to reset direction, making sure cylinder rod fully soaked inside DOP liquid, in this way it can prolong service life of seal ring.

3 Check sensitivity of the equipment heating system, if anything goes wrong, please fix the problem as soon as possible.

4 When equipment isn’t working, please turn off heating system timely, for not only it prevents potential danger also avoids low foaming quality cuz polyol material long-time heating.

5 Make sure turning on and off heating system in correct order. When turning on, first start main power,then turn on heating system; when turning off, first stopping heating system then turning off main power.

6 Remember to check if there’s enough oil inside oil-water separator and the water expelled from the separator;

Hot Searches