NaN / 0

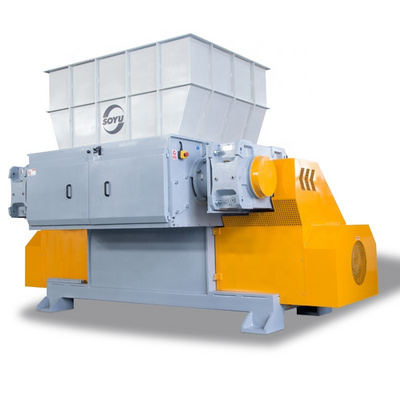

cheap plastic pipe crusher scrap textile shredder machine single shaft shredder

Get Latest Price

US$ 11500

≥1 Sets

Quick Details

Max.Production Capacity (kg/h):

10000

Place of Origin:

Henan, China

Production Capacity (kg/h):

300 - 10000 kg/h

Brand Name:

Derui Brand

Product Details

Single Shaft Shredder

Product Description2

Product introduction and application

Single shaft shredder is used to pre-crush different kinds of plastic materials, especially shredding very large and hard plastics such as lumps,barrels,pipes wood, die material, big block material, film to small pieces for easy reprocessing, storage and transportation, creating new value from reusable wastes.

Our company has many years experience in manufacturing the plastic shredder machine, we can produce shredder machine according to your requirement.

Working Principle3

Working Principle

The material enters into the shredder box through the feeding system, and the shredder system is mounted on the box, which is composed of knife shaft, moving knife, fixed knife and screen. The pushing system will push the material near the blade, and the material will be torn, squeezed and cut by the shredding blade. If the size of the torn material is smaller than the aperture of the sieve, the material will be discharged from the hole. If the size of the sieve is larger than the aperture of the sieve, the material will be cut for many times. According to the different physical properties of the material, the design of the single shaft shredder will be different

Product Feature1

Features

1. Designed with blades rotor and static knife. Blades rotor is composed of a base shaft and several shape quadrilateral knife block. The knife block has 4 sharp edges and can be reused. The knife blocks are along the axis of the base and fixed in multiple rows into type V, and finally fastened with screws in the radical axis. V blades blocks will rotate with the based shaft together, finally comprise a blade knife rotor. The static knife is fixed on the machine frame.

2. Screen, used to control discharged output size, can be customized ac cording to different needs.

3. Hydraulic cylinder, used to push scraps forward to blade rotor . The speed is stable and adjustable, and the propulsive force is large and uniform.

4. M ain shaft is driven by a gear box, smooth operation, low noise, large torque .

5. PLC control system with automatic overload protection and auto-reverse switch

Technical Parameter

Best Service

Pre-sale services,we do

1. Select equipment model;

2.Deign and manufacture products according to clients' special requirement;

3. Train technical personnel for clients.

Services during the sale,we do

1. Pre-check and accept products ahead of delivery;

2. help clients to draft solution.

After-sales service,we do

1. Assist clients to prepare for the first construction scheme;

2. Install and debug the equipment;

3. Provide technical exchanging;

4. Provide spare parts for big items.

FAQ

Q:What is the MOQ?

R:MOQ is 1 set,we allow OEM and sample order,but the cost are paid by your side.

Q: Where is your factory located? How can I visit there?

R: Our factory is located in Zhengzhou City, Henan Province, China.Contact us ahead before you go visit,then we can fully arrange the schedule and meet you.Welcome to visit us!

Q: What is the warranty time of your products?

R: The warranty time is 12 months from the date of the commissioning.After the warranty, any questions and needs,please contact us.

Q: How does your factory do regarding quality control?

R: All products have to pass strict inspection before they ship out.And we have gained ISO9001:2008 authentication.If you need other certificate and qualit control,please contact us.