NaN / 0

2023 hay round pine grass bale making baling packing machine for alfalfa straw corn silage baler and wrapper machine price sale

Get Latest Price

US$ 3500

≥1 Sets

US$ 3000

≥5 Sets

US$ 2000

≥10 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

QD

Application:

Silage baler wrapper

Dimension(L*W*H):

2200*1500*1500mm

Product Details

Livestock Machine Hay Silage Grass Corn Stalk Rice Straw Baler and Wrapper Machine rhodes grass baling machines

Product Description

Description of straw silage baler wrapper machine

This silage baling machine is a fully-automatic product, it can match with 5.5kw motor. and operating speed can reach 60-70bundles/h. There are 2-4 coated layer, and bale density is 450kg/m3. Round shape with film has long storage time that is useful for feeding animals. Hay and straw baler machine is suitable for nearly all kinds of silage,fresh or dry straws of wheat, rice, soybean, corn, etc.

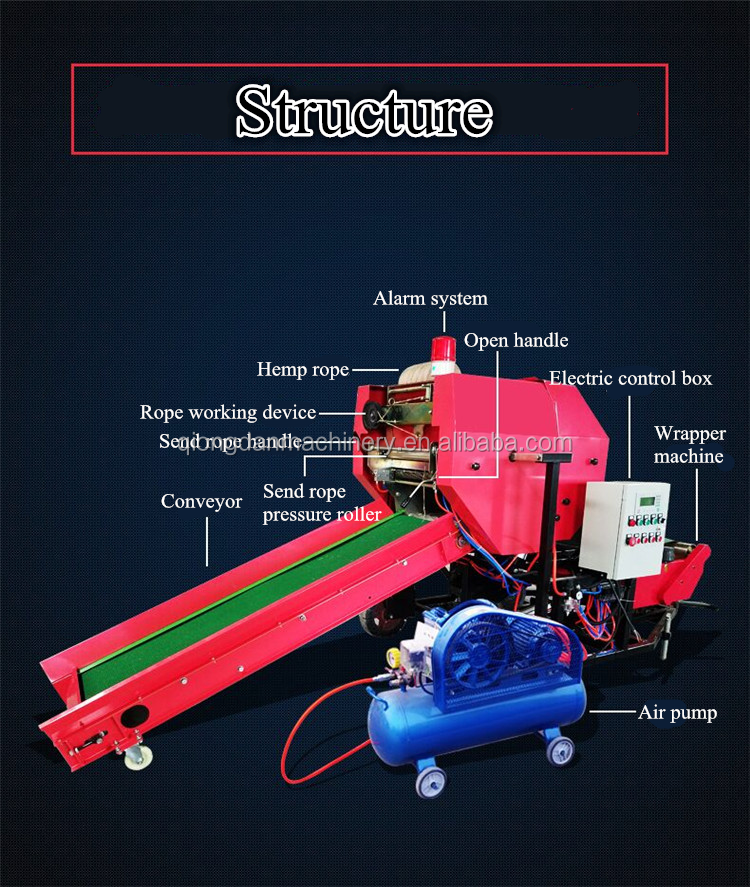

Structure of straw silage baler wrapper machine

Parameter of straw silage baler wrapper machine

| Model | QDDK-1 | QDDK-2 |

| Power | 5.5+0.55kw | 5.5+0.55kw |

| Capacity | 3-5t/h | 4-6t/h |

| Baler size | 550*520mm | 550*520mm |

| Bale size | 65-75kg | 65-75kg |

| Film layer | 2-4 layer | 2-4 layer |

| Wrapper efficiency | 18s/2 layer; 24s/3 layer; 32s/4 layer | 18s/2 layer; 24s/3 layer; 32s/4 layer |

| Machine size | 2200*1500*1500mm | 2400*1500*1650mm |

| Weight | 750kg | 800kg |

Advantage

s

of straw silage baler wrapper machine

1.There is no any influence on wrapped feed even they are exposed in the weather and it can be stacked in the open air for 2 or 3 years.

2.The machine is equipped with a control cabinet and warning light,so the operation is pretty safe and easy.

3.The wrapped feed has high quality and the utilization of it can reach 98%.

Crusher part

The silage or grass are smashed by a smashing part, which destroys the hard stem segments on the surface of the straw by crushing, slitting, squeezing them. Finally, it processes the straw which cannot be directly eaten by the livestock into filamentous type. Such forage can keep its original nutrients that is easy to digest and absorb for livestock. Cattle and sheep like this kind of forge very much. The straw after smashing is easy to bundle, improving the efficiency of fermentation and decomposition of crude fiber and improving palatability.

Baling part

The forage is fed into the working chamber of the baler quickly, uniformly and evenly for compression. When the weight of each bundle reaches about 80kg.When the signal wheel rotates at a constant speed, the winding clutch handle can be pulled and the fine rope can be used for baling.

After baling,the rope is cut, and user starts up the opening handle to make the bundles come out. In this way, the bundling process is completed.

Wrapping part

The bales are placed on the two parallel belts of the wrapping machine, and the wrapping switch drives the bales by rotating frame to rotate. The bales stretch the plastic film to wrap automatically. Then,users can set the number of coating layers(2 to 4 layers).

How to prepare before use baling and wrapping machine?

First, connect the main power supply, and adjust all delayer and timers for a total of five. Then, adjust the air pressure to 6MPa. Place the film on the holder and fix it;

Next, turn the switch to the automatic gear and open the emergency stop button. Set the procedure to be automatic. Press the button to start the machine;

Finally,pass the rope. Firstly, pass the rope through the barrel. Then there is a compression port. After pulling the rope out, adjust the screw to tighten and pass through the guide hole. In the end, let the rope roll from the wire feeding tube and all in finished.

Details

of straw silage baler wrapper machine

Silage baler and wrapper machine also can match with diesel engine as power.

Related Products

Hot Searches