NaN / 0

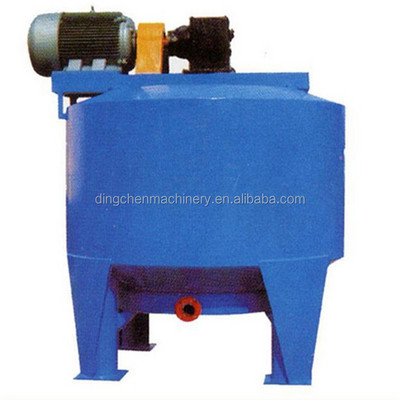

High quality and efficiency Pulper/Pulping Equipment/Paper Machinery

Get Latest Price

US$ 6000

≥1 Sets

US$ 5500

≥2 Sets

Quick Details

Type:

Pulping Equipment

Production Capacity:

Other

Max. workable width:

Other

Place of Origin:

Henan, China, Henan China (Mainland)

Product Details

Product Description

high quality Pulper/Pulping Equipment/Paper Machinery

♥ Description

We can according your demand provide you a suitable produce scheme

Low consisteny hydrapulper

Model‘D’hydrapulper is used for continuously pulping waste paper. The pulper

tank shape is‘DR’ structure, increasing the contact times between the rotor and

pulp, so the pulping time is shorter. The power transmission has pulley transmission

and reducer transmission two ways.

“D” type hydrapulper, hydrapurger II, drum screen, ragger and grapple make up of

continuous pulping and discharging system. This system is used for processing OCC, AOCC, etc, removing the plastics, styrol foam and other light and heavy impurities being broken and flow through the screen plate, so the capacity is higher and the pulp is cleaner.

|

Item \Type |

15m³D |

20m³D |

25m³D |

30m³D |

35m³D |

|

Volume (m³) |

15 |

20 |

25 |

30 |

35 |

|

Productivity(t/d) |

60-150 |

100-200 |

120-300 |

150-350 |

200-400 |

|

Power(KW) |

160 |

185 |

250 |

280 |

315 |

|

Consistency (%) |

3-5 |

||||

|

Item \Type

|

40 m³D |

45m³D |

50m³D |

60m³D |

75m³D |

|

Volume (m³) |

40 |

45 |

50 |

60 |

75 |

|

Productivity(t/d) |

260-450 |

280-500 |

300-550 |

360-700 |

420-850 |

|

Power(KW) |

355 |

400 |

450 |

560 |

630 |

|

Consistency (%) |

3-5 |

||||

|

Item \Type |

90m³D |

100m³D |

127m³D |

145m³D |

|

|

Volume (m³) |

90 |

100 |

127 |

145 |

|

|

Productivity(t/d) |

550-100 |

650-1100 |

760-1300 |

880-1500 |

|

|

Power(KW) |

160 |

185 |

250 |

280 |

|

|

Consistency (%) |

3-5 |

||||

High Consistency Hydrapulper

High consistency hydrapulper is used for pulping waste paper in high consistency. The rotor structure combines triple-thread and tooth profile bar and produce intense friction for fiber-to-fiber, so it can speed up the defibering of waste paper.

High consistency hydrapulper, hydrapulper III and drum screen is made up of intermittent high consistency pulping and discharging system.

|

Item \Type |

3m³ |

5m³ |

8m³ |

10m³ |

15m³ |

|

Nominal Volume (m³) |

3 |

5 |

8 |

10 |

15 |

|

Capacity (t/d) |

8-15 |

15-22 |

20-35 |

25-50 |

35-75 |

|

Power(KW) |

75 |

132 |

160 |

220 |

315 |

|

Consistency (%) |

14±2 |

||||

|

Item \Type |

20m³ |

25m³ |

30m³ |

40m³ |

50m³ |

|

Nominal Volume (m³) |

20 |

25 |

30 |

40 |

50 |

|

Capacity (t/d) |

50-90 |

70-120 |

80-150 |

120-210 |

150-260 |

|

Power(kw) |

400 |

450 |

560 |

710 |

900 |

|

Consistency (%) |

14±2 |

||||

Middle consistency paper pulp hydrapulper is used for middle consistency broken of commodity pulp board.

Middle consistency hydrapulper are used in the production line of wasted paper deinking in pulp-making industry. It has the ability to pulp wasted paper promptly, thick liquid board and paper machine decrease paper and makes its effort to have protected the iber original character. When added the chemical, it can make the ink particle and impurity to separate out form the fiber to get the thick liquid with high white degree. Has the advantages of great production ability, good efficiency pulping, saving steaming medicine and convenient to operating and maintaining.

|

Item/Type |

FSV1-06 |

FSV1-09 |

FSV1-12 |

FSV2-16 |

FSV2-20 |

FSV2-26 |

|

Nominal volume(m³) |

6 |

9 |

12 |

16 |

20 |

26 |

|

Production (t/d) |

20-50 |

30-80 |

40-100 |

50-130 |

60-160 |

80-210 |

|

Power(KW) |

45-90 |

55-132 |

75-160 |

110-250 |

132-315 |

160-355 |

|

Consistency (%) |

6-7 |

|||||

|

Item/Type |

FSV3-33 |

FSV3-43 |

FSV3-56 |

FSV4-72 |

FSV4-90 |

FSV4-120 |

|

Nominal volume(m³) |

33 |

43 |

56 |

72 |

90 |

120 |

|

Production (t/d) |

100-240 |

140-310 |

180-400 |

240-540 |

300-680 |

400-900 |

|

Power(KW) |

200-630 |

250-710 |

315-800 |

500-1200 |

630-1500 |

630-1500 |

|

Consistency (%) |

6-7 |

|||||

♣PICTURES

Packaging & Shipping

♣packing

1. The dryer is packed with wood chips for protecting its surface 2. The large diameter roll is packed with wood chips. 3. The steel rolls are packed with plastic film and straw ropes 4. Speed reducer, oil station, and suction box, hydraulic station is packed with wooden box. 5. Electric control cabinet is packed with three-ply board box 6. Some parts are nude cargo

Hot Searches