NaN / 0

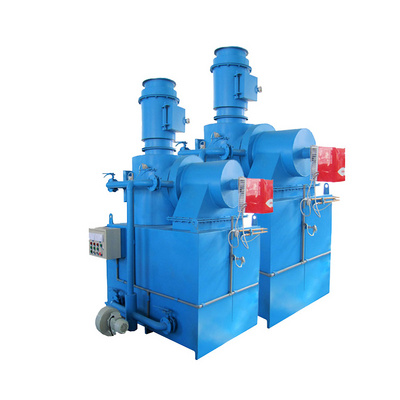

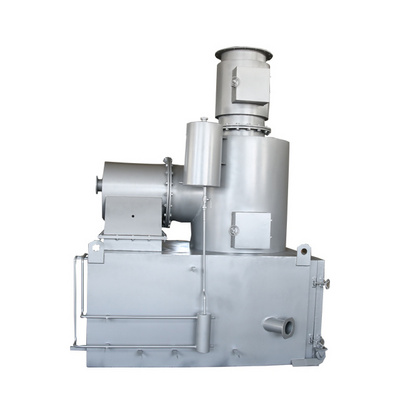

30kg 50kg 100kg 150kg 200kg 600KG pet animal hospital medical garbage waste incinerator

Get Latest Price

US$ 4850

≥1 Sets

Quick Details

Production Capacity:

200L/H

Place of Origin:

Henan, China

Brand Name:

LUY

Model Number:

WFS

Product Details

WFS series of domestic (medical) waste incinerators adopt the most advanced incineration method of one pyrolysis gasification + mixed combustion around the wind + two incineration + burn out treatment. The design of the primary combustion chamber of the incinerator uses gasification incineration technology to make the air temperature in the incinerator move from 200 ℃ to 400 ℃, so there will be no frit, slag sintering and other problems in the incineration process. The secondary combustion chamber is equipped with a secondary combustion burner and an annular air supply device. At high temperature, the combustible gas in the flue gas can be fully burned, and the gas produced by the gasifier can be fully mixed with the air for combustion with high efficiency, so as to prevent the carbon material in the gas flame from overflowing and burning late. When the flue gas enters the high temperature combustion chamber, the tangential entry and the tangential entry of combustion supporting air are adopted, so that the flue gas can be fully combusted again in the combustion chamber and the rotary air flow is used for flue gas dust removal. The residence time of the incineration flue gas in the furnace is more than 2 seconds, so that the combustible gas in the flue gas and the combustible in the fly ash are completely incinerated. The upper part of the incinerator is equipped with a dry tail For gas purification equipment, hydrogen chloride and sulfur oxide produced in incineration are adsorbed to treat the odor in flue gas and other components which are decomposed under high temperature. The flue gas purification system is equipped with calcium hydride filter brick and acid gas for neutralization reaction to achieve the purpose of adsorption of acid gas and purification of tail gas. So that the harmful components in the flue gas can be reduced below the value specified in the national pollution control standard for hazardous waste incineration (GB18484-2001) and other standards.

|

Model Item |

WFS-30 |

WFS-50 |

WFS-150 |

WFS-300 |

WFS-500 |

|

Capacity |

20-30kg/Item(3-6Item/day) |

30-50kg/Item(3-6Item/day) |

100-150kg/Item(3-6Item/day) |

200-300kg/Item(3-6Item/day) |

300-500kg/Item(3-6Item/day) |

|

Capacity size(L×B×H)m |

1.45×0.9×1.75 |

1.8×1.15×3 |

2×1.4×3.5 |

2.2×1.4×3.8 |

3×2×4.8 |

|

Wasteinlet size(mm) |

400×600 |

620×800 |

760×960 |

900×1100 |

1080×1280 |

|

Chimney(mm) |

Outer Diameter280 |

Outer Diameter280 |

Outer Diameter300 |

Outer Diameter400 |

Outer Diameter460 |

|

Air Fan |

0.37KW |

0.37KW |

0.5KW |

1.1KW |

1.1KW |

|

Combustion Bumer |

Power 0.11KW, oil Consumption 4-6kg/h |

Power, 0.11KW, oil Consumption 4-10kg/h |

Power, 0.11KW, oil Consumption 5-12kg/h |

Power, 0.22KW, oil Consumption 7-14kg/h |

Power, 0.22KW, oil Consumption 7-14kg/h |

|

Re-combustion Bumer |

Power 0.11KW, oil Consumption 4-6kg/h |

Power 0.11KW, oil Consumption 4-10kg/h |

Power 0.22KW, oil Consumption 7-14kg/h |

Power 0.37KW, oil Consumption 10-20kg/h |

Power 0.37KW, oil Consumption 15-26kg/h |

|

Voltage |

380V 220V |

380V 220V |

380V 220V |

380V 220V |

380V 220V |

|

Weight(kg) |

2300 |

4000 |

7000 |

8000 |

13000 |

1.What is the max size can you do?

Reply:According to your product size to customize.Diameter from 800 mm to 1500mm.

2.How many products can you treat for one circle ?

Reply:According to your product size and packages size.

3.How long to finish one circle ?

Reply:Generally is one hours. is up to your products’ packing and product details.

4.Is it manual or automatic operation ?

Reply:We have full automatic type and semi-automatic type.

5.Can we install the equipment by ourselves ?

Reply:Of course ,we have full set drawing which will send to you after order.

6.lf your engineer is aviliable to oversea to install ?

Reply:,if you need ,we can arrange the engineer to install for you.

Hot Searches